Automatic rib processing machine

A processing machine and automatic umbrella technology, applied in the direction of walking sticks, etc., can solve the problems of low efficiency, high cost, and difficulty in quality assurance of manual processing of umbrella ribs, and achieve the effects of smooth movement, reduced labor costs, and improved processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

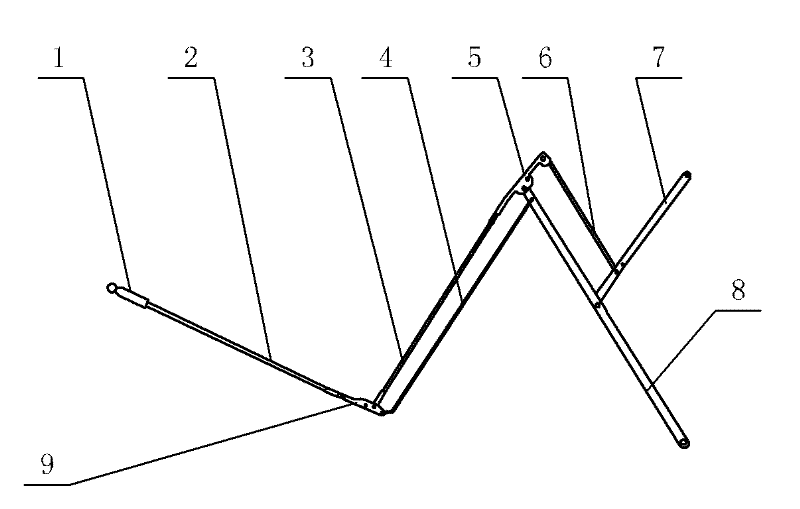

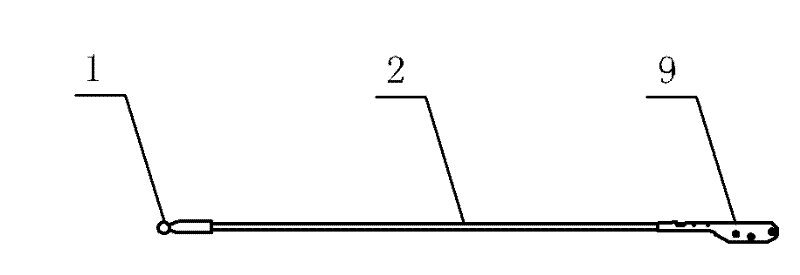

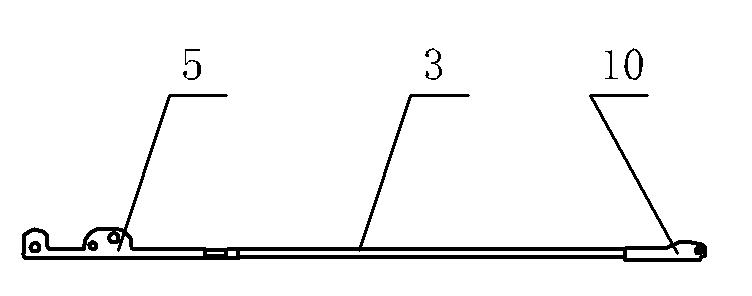

[0043] The automatic umbrella rib processing machine of the present invention will be further explained and described below by taking the automatic glass fiber rib processing machine for processing the first-grade ribs of glass fiber materials as an example.

[0044] refer to Figure 7 , 8 , the automatic fiberglass rib processing machine in this example is composed of glass fiber blanking mechanism, rib conveying mechanism, saddle pushing device, stamping device, power mechanism, unloading box 29 and other parts arranged on the frame. The glass fiber unloading mechanism is arranged at the front end of the frame 11, suspended above the rib conveying mechanism, and the stamping device is located in front of the pushing action direction of the saddle pushing device; the missing material box 29 is arranged on the frame 11 rear lower part of the tail. The rib conveying mechanism is a double conveying chain mechanism intermittently driven by a ratchet mechanism. The conveying ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com