Novel CT (Captive Test) machine data acquiring and imaging system

A data acquisition and imaging system technology, applied in computerized tomography scanners, echo tomography, etc., can solve the problems of high current in X-ray tubes, great harm to human body, high waste rate, etc., and achieve simple physical structure and low radiation dose , the effect of high work stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

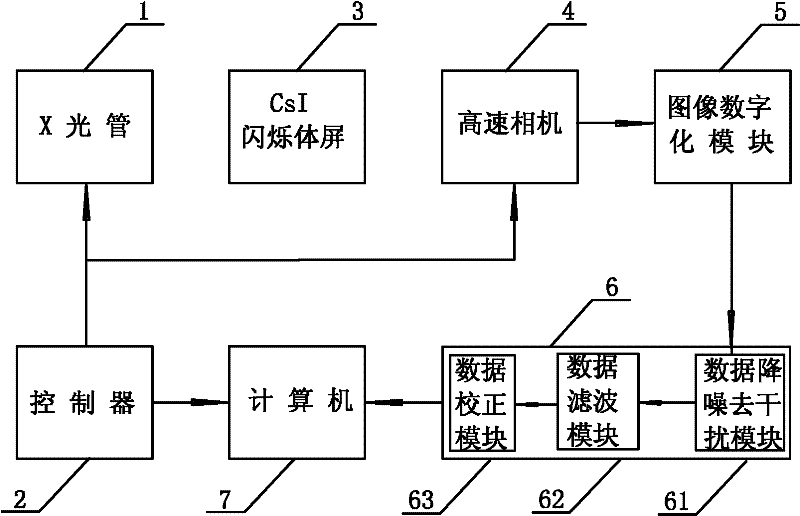

[0016] like figure 1 As shown, a novel CT machine data acquisition imaging system includes an X-ray tube 1, a controller 2, a CsI scintillator screen 3, a high-speed camera 4, an image digitization module 5, a data processing module 6, and a computer 7; the controller 2 Electrically connect the X-ray tube 1, the high-speed camera 4 and the computer 7 respectively, the high-speed camera 4, the image digitization module 5, the data processing module 6, and the computer 7 are electrically connected in sequence; use the CsI scintillator screen 3 as the imaging screen When, the CsI scintillator screen 3 is not electrically connected with the controller 2, it is between the detected object and the high-speed camera 4;

[0017] The data processing module 6 includes a data noise reduction and interference removal module 61 , a data filtering module 62 , and a data correction module 63 connected in sequence.

Embodiment 2

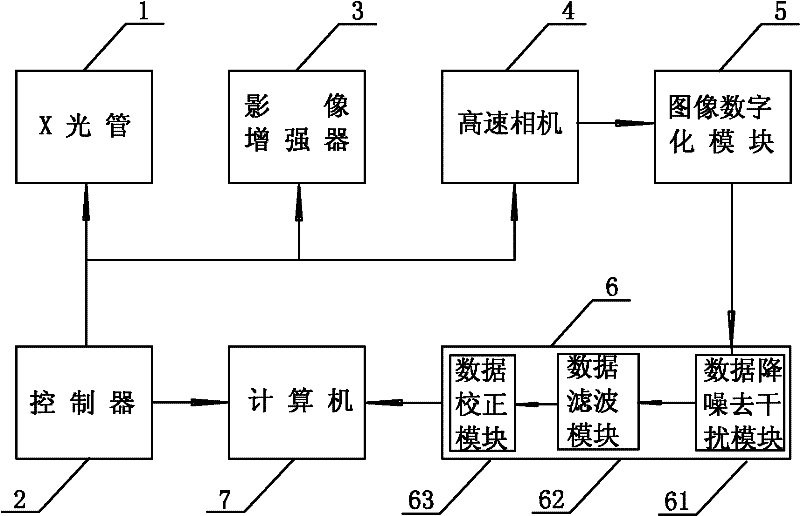

[0019] like figure 2 As shown, a novel CT machine data acquisition imaging system includes an X-ray tube 1, a controller 2, an image intensifier 3, a high-speed camera 4, an image digitization module 5, a data processing module 6, and a computer 7; the controller 2 The X-ray tube 1, the image intensifier 3, the high-speed camera 4 and the computer 7 are respectively electrically connected, and the high-speed camera 4, the image digitization module 5, the data processing module 6, and the computer 7 are electrically connected sequentially;

[0020] The data processing module 6 includes a data noise reduction and interference removal module 61 , a data filtering module 62 , and a data correction module 63 connected in sequence.

[0021] The working principle and working process of the present invention are as follows:

[0022] like figure 1 , 2 As shown, the detected object is placed between the X-ray tube 1 and the CsI scintillator screen 3 (or image intensifier 3); the X-r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com