Method and device for purifying waste incineration smoke

A technology for incinerating flue gas and waste, applied in chemical instruments and methods, combined devices, separation methods, etc., can solve problems such as high moisture content, bag dust collector paste, black smoke, etc., to avoid resynthesis temperature, Avoid sticky bags and efficiently remove pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

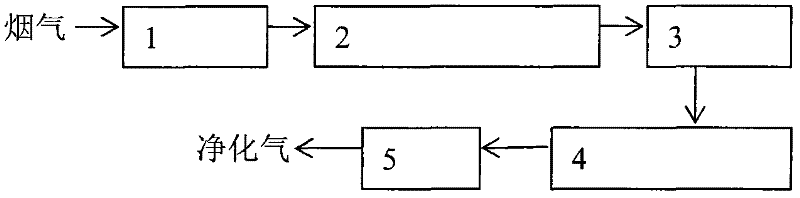

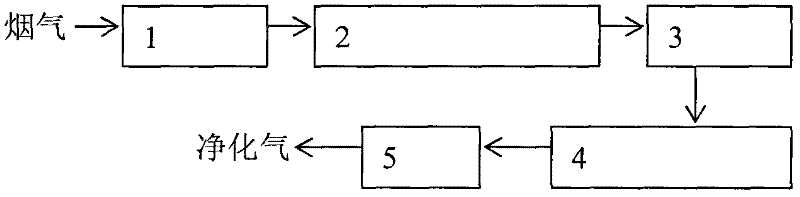

[0025] This example is an example of flue gas purification in medical waste incineration. The flue gas generated in the waste incineration process is sent to the quenching absorption tower 1 through the flue gas pipeline. The flue gas is in countercurrent contact with the lye to remove most of the acidic substances and organic pollutants, and the temperature drops to 100°C within 2 seconds. Then enter the heater 2, use the high-temperature flue gas of fuel combustion and the flue gas after wet acid removal to heat up, and the temperature rises to about 130 ° C and enter the activated carbon adsorption device 3 for deep purification, and the purified flue gas enters the bag type. After the dust collector 4 performs dust removal, the purified gas is discharged from the chimney 5 . The emission of harmful substances in the flue gas purified by this method is lower than the maximum allowable emission standard.

Embodiment 2

[0027] This example is an example of flue gas purification in domestic waste incineration. The difference from Example 1 is that after the flue gas generated in the waste incineration process is sent to the quenching absorption tower through the flue gas pipeline, the absorption tail gas directly enters the activated carbon adsorption device for deep purification, and the deeply purified flue gas enters the heater, which is burned with fuel. The high-temperature flue gas from the cyclone is mixed with the flue gas after wet acid removal to heat up, and the temperature rises to about 130 °C and enters the bag filter for dust removal, and the purified gas is discharged from the chimney 5. The emission of harmful substances in the flue gas purified by this method is lower than the maximum allowable emission standard.

Embodiment 3

[0029] This example is similar to Example 1, the difference is that after the flue gas enters the heater 2, the high temperature flue gas generated by the incinerator and the hot air generated after heat exchange with the air are mixed with the flue gas after wet acid removal to heat up. The emission of harmful substances in the flue gas purified by this method is lower than the maximum allowable emission standard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com