Porous soil block

A technology of porosity and mud, which is applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of not being able to fully perform the role of ecological mud, failing to achieve full cooperation, and insufficient matching water. , to achieve the effect of ensuring ecological stability and structural stability, inhibiting material separation, and improving the coordination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to analyze the effects obtained by using fiber reinforcement materials, hemp fibers of surface porous natural fibers, hydrophilic synthetic fibers-polyvinyl alcohol fibers, and general synthetic fibers-polypropylene were prepared. Refer to Table 1 for the physical properties of the fiber reinforced material.

[0035] 【Table 1】

[0036] fiber reinforced material

Elastic coefficient (GPa)

61*10 3

1.1*10 3

4.5*10 3

1.26

1.26

1.14

Fiber length (mm)

3

6

19

Tensile strength (MPa)

510

686

896

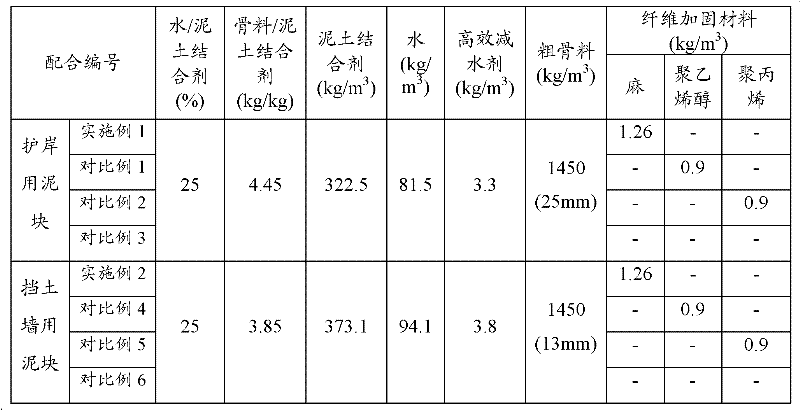

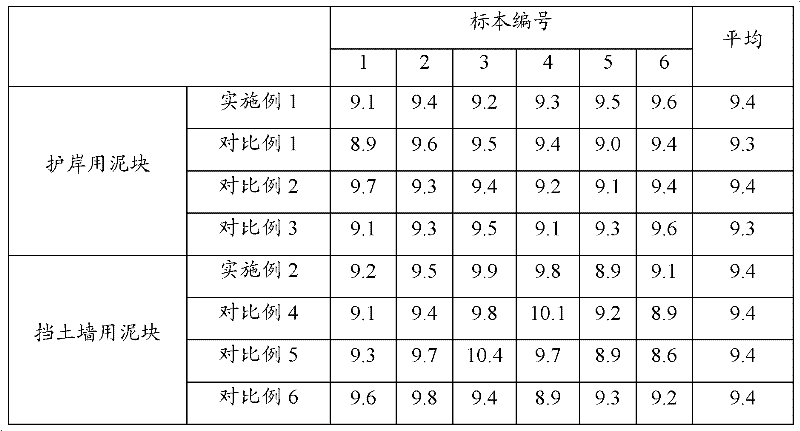

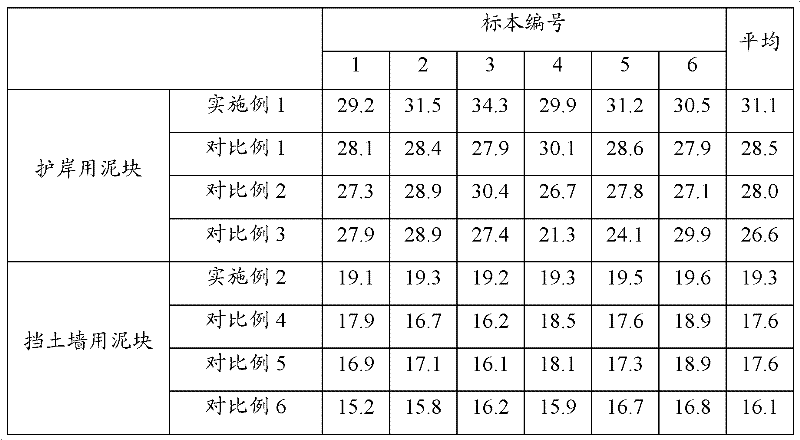

[0037] Table 2 is a comparison table of performance experiments based on the presence or absence of fiber-reinforced materials and the type of fiber-reinforced materials.

[0038] 【Table 2】

[0039]

[0040] In Table 2, the amount of water (mixed water) in the water / soil binder (%) is exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com