Preparation process of alkaloid tabersonine

A preparation process and the technology of taponin, which are applied in the field of preparation process of alkaloid taponin, can solve the problems of high cost, unfavorable large-scale production, difficulty in purification and purification and separation of resin column, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

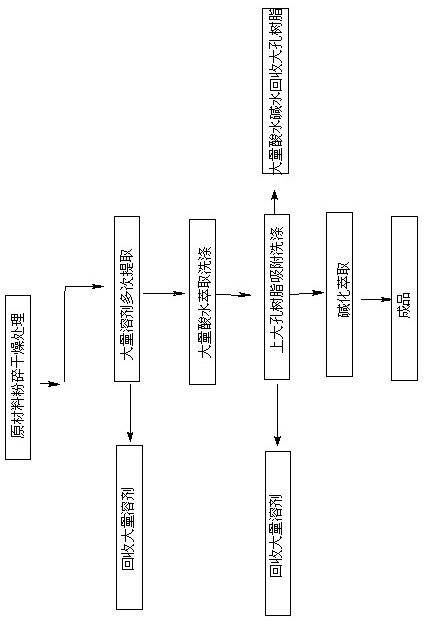

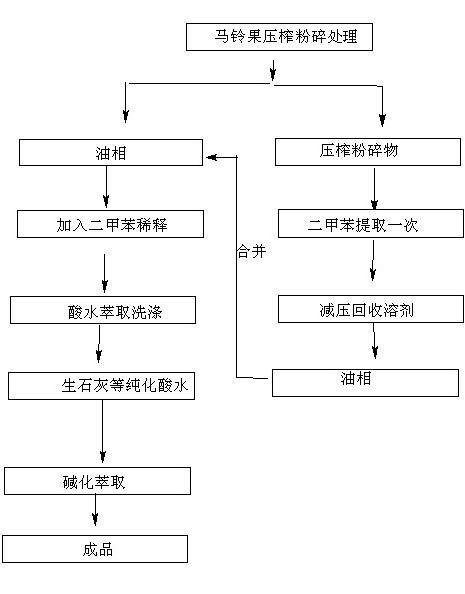

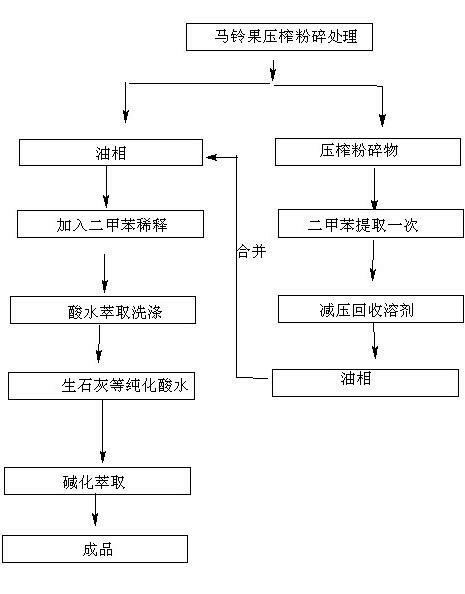

Method used

Image

Examples

Embodiment 1

[0024] One, the pretreatment of potato seed: the mature potato seed 50Kg, without drying, directly cold press with oil press, collect oil phase weight 10Kg, press cake 38Kg, pulverize into 80 orders with pulverizer, wait use.

[0025] 2. Solvent extraction: 190Kg of xylene (content ≥ 98%, boiling point 138.35°C-144.42°C) was added to 38Kg of crushed cake residue, stirred for 3 hours at 35°C, cooled to 20°C, pumped Filter to dryness, and evaporate the solvent to dryness under reduced pressure to obtain 3Kg of oil, which is set aside.

[0026] 3. Extraction and washing with acid water: add 6.5Kg of oil to 65Kg of xylene and stir for 30 minutes; the first extraction and washing: add 50Kg of sulfuric acid aqueous solution with a mass percentage concentration of 2.5%, stir for 1 hour, stand still for 2 hours, layer and separate The organic phase and the acidic aqueous phase are produced, and the acidic aqueous phase is I.

[0027] The second extraction and washing: add 50Kg of su...

Embodiment 2

[0032] One, the pretreatment of potato seed: the mature potato seed 100Kg, without drying, directly cold press with oil press, collect oil phase weight 25Kg, press cake 70Kg, pulverize into 100 orders with pulverizer, wait use.

[0033] 2. Solvent extraction: Add 140Kg of xylene (content ≥ 98%, boiling point 138.35°C-144.42°C) into 70Kg of crushed cake residue, stir for 3 hours at 55°C, cool down to 20°C, and suction filter to dryness , The solvent was evaporated to dryness under reduced pressure to obtain 5Kg of oil.

[0034] 3. Sour water extraction and washing: Add 15Kg of oil to 75Kg of xylene, and stir for 30 minutes;

[0035] The first extraction and washing: Add 50Kg of 3.5% sulfuric acid aqueous solution, stir for 1 hour, stand still for 2 hours, separate layers, and the acidic aqueous phase is I.

[0036] The second extraction and washing: Add 50Kg of 3.5% sulfuric acid aqueous solution to the organic phase, stir for 1 hour, stand still for 2 hours, separate layers,...

Embodiment 3

[0042] One, the pretreatment of potato seed: the ripe potato seed 100Kg, need not dry, directly cold press with oil press, collect oil phase weight 25Kg, press cake 70Kg, pulverize into 90 orders with pulverizer, wait use.

[0043] 2. Solvent extraction: Add 175Kg of xylene (content ≥ 98%, boiling point 138.35°C-144.42°C) into 70Kg of crushed cake residue, stir for 3 hours at 45°C, cool down to 20°C, and suction filter to dryness , The solvent was evaporated to dryness under reduced pressure to obtain 5Kg of oil.

[0044] 3. Extraction and washing with acid water: Add 15Kg of oil to 105Kg of xylene, and stir for 30 minutes;

[0045] The first extraction and washing: Add 50Kg of 3.0% sulfuric acid aqueous solution, stir for 1 hour, stand still for 2 hours, separate layers, and the acidic aqueous phase is I.

[0046] The second extraction and washing: Add 50Kg of 3.0% sulfuric acid aqueous solution to the organic phase, stir for 1 hour, stand still for 2 hours, separate layers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com