Aniline/2,3-dimethylaniline copolymer

A technology of dimethylaniline and copolymers, which is applied in the field of copolymers, can solve the problems of low electrical conductivity of products, and achieve the effects of simple operation, convenient source of raw materials, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0020] Add 50ml of distilled water and 0.023mol of concentrated hydrochloric acid into the reactor, stir to mix evenly; add 0.008mol of aniline and 0.004mol of 2,3-dimethylaniline, stir to mix evenly; weigh 0.01mol of ammonium persulfate and dissolve in 25ml of distilled water, add the obtained ammonium persulfate solution dropwise into the reactor, and react at room temperature for 2 hours; filter with suction, wash the filter cake with distilled water until the filtrate is colorless; dry the filter cake at 60°C for 6 hours, take it out and grind it, and obtain Aniline / 2,3-Dimethylaniline Copolymer. The conductivity measured by a four-probe conductivity meter is 0.0078S / cm.

[0021]

experiment example 2

[0023] Add 50ml of distilled water and 0.089mol concentrated hydrochloric acid into the reactor, stir to mix evenly; add 0.016mol aniline and 0.004mol 2,3-dimethylaniline, stir to mix evenly; weigh 0.025mol ammonium persulfate and dissolve in 25ml of distilled water, add the obtained ammonium persulfate solution dropwise into the reactor, and react at room temperature for 10 hours; filter with suction, wash the filter cake with distilled water until the filtrate is colorless; dry the filter cake at 60°C for 8 hours, take it out and grind it to obtain Aniline / 2,3-Dimethylaniline Copolymer. The conductivity was measured with a four-probe conductivity meter to be 0.15 S / cm.

[0024]

experiment example 3

[0026] Add 50ml of distilled water and 0.22mol concentrated hydrochloric acid into the reactor, stir to mix evenly; add 0.004mol aniline and 0.016mol 2,3-dimethylaniline, stir to mix evenly; weigh 0.05mol ammonium persulfate and dissolve in 25ml of distilled water, add the obtained ammonium persulfate solution into the reactor, and react at room temperature for 12 hours; filter with suction, wash the filter cake with distilled water until the filtrate is colorless; dry the filter cake at 60°C for 12 hours, take it out and grind it, and obtain aniline / 2,3-Dimethylaniline copolymer. The conductivity measured by a four-probe conductivity meter is 0.00057S / cm.

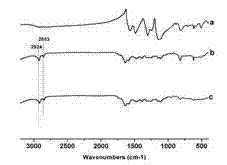

[0027] As can be seen from the accompanying drawings and Examples, the aniline / 2,3-dimethylaniline copolymer provided by the invention effectively solves the problem of poor electrical conductivity of poly-2,3-dimethylaniline, and its conductivity can reach 0.15S / cm, it is expected to be used in electronic components, e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com