Method for preparing fluoridated hydroxyapatite by one step

A technology of fluorinated hydroxyapatite and potassium fluoride, which is applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., to achieve the effects of reduced preparation costs, simple process flow, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

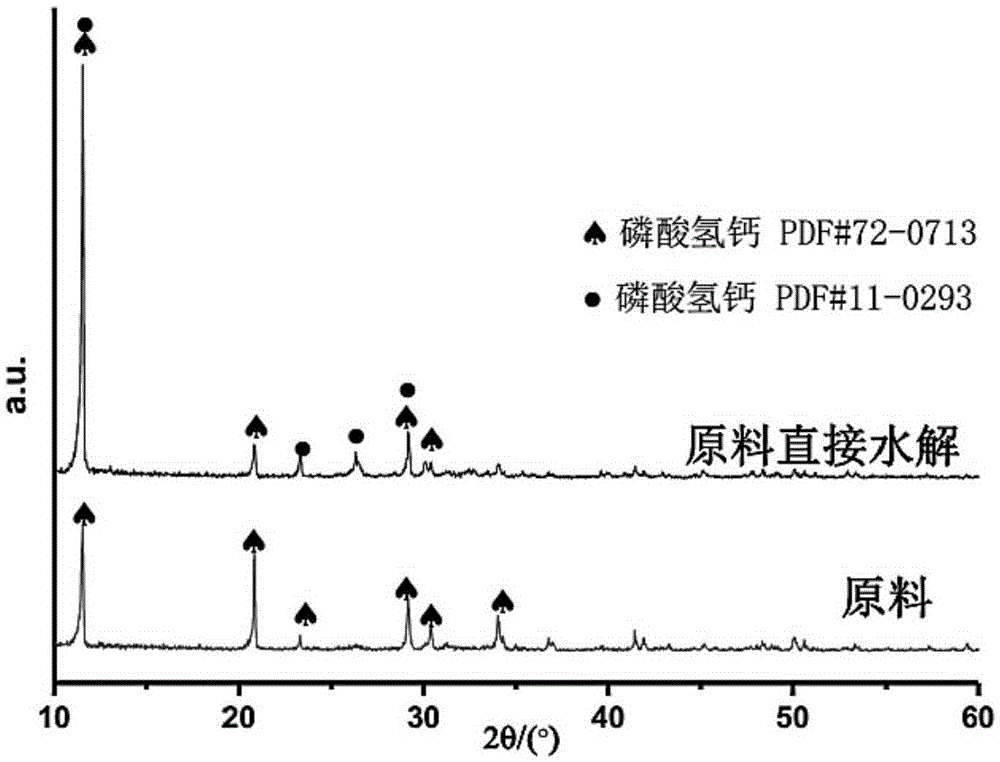

Method used

Image

Examples

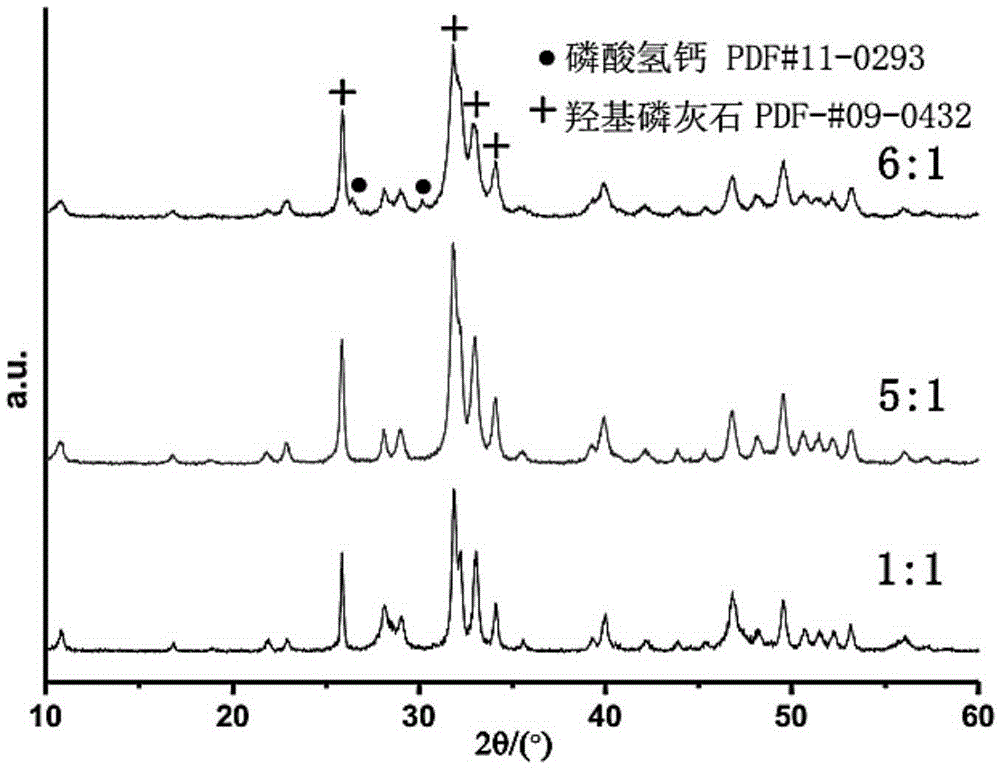

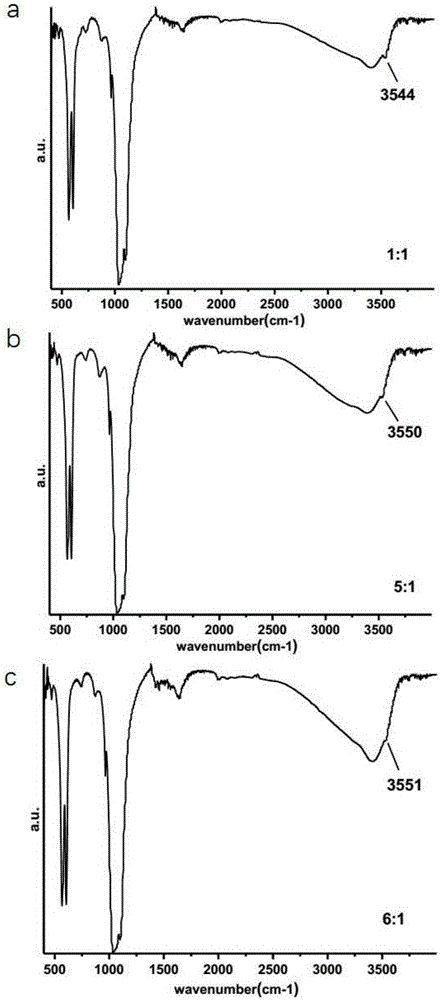

Embodiment 1

[0027] This embodiment includes the following steps: dissolving 0.02 mol of calcium hydrogen phosphate dihydrate in 200 mL of ultrapure water, and electromagnetically stirring for 30 minutes to form a uniform suspension. Dissolve 0.02mol potassium fluoride dihydrate in 120mL ultrapure water, and stir with a glass rod to form a uniform solution. The potassium fluoride solution was added dropwise to the calcium hydrogen phosphate solution at a rate of 0.05mL / s, and the electromagnetic stirring was continued, and the upper opening of the reaction vessel was covered and sealed, and reacted at room temperature for 4 hours, and then stood still for 12 hours. The precipitate was washed and dried at 80° C. for 3 hours to obtain fluorinated hydroxyapatite.

Embodiment 2

[0029] This embodiment includes the following steps: dissolving 0.02 mol of calcium hydrogen phosphate dihydrate in 200 mL of ultrapure water, and electromagnetically stirring for 30 minutes to form a uniform suspension. Dissolve 0.004mol potassium fluoride dihydrate in 120mL ultrapure water, and stir with a glass rod to form a uniform solution. Potassium fluoride solution was added dropwise to the calcium hydrogen phosphate solution at a rate of 0.05mL / s, and the solution was mixed continuously under electromagnetic stirring, and the upper opening of the reaction vessel was covered and closed, and reacted at room temperature for 4 hours, and then stood still for 12 hours. The precipitate was washed and dried at 80°C to obtain fluorinated hydroxyapatite.

Embodiment 3

[0031] Dissolve 0.02mol of calcium hydrogen phosphate dihydrate in 200mL of ultrapure water, and stir it electromagnetically for 30 minutes to form a uniform suspension. Dissolve 0.0033mol potassium fluoride dihydrate in 120mL ultrapure water, and stir with a glass rod to form a uniform solution. Potassium fluoride solution was added dropwise to the calcium hydrogen phosphate solution at a rate of 0.05mL / s, and the solution was mixed continuously under electromagnetic stirring, and the upper opening of the reaction vessel was covered and closed, and reacted at room temperature for 4 hours, and then stood still for 12 hours. The precipitate was washed and dried at 80°C to obtain fluorinated hydroxyapatite and a small amount of calcium hydrogen phosphate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com