Antifreezing method of sulfide ore bioleaching ore heap

A technology for bioleaching and sulfide ore, applied in the direction of improving process efficiency, can solve problems such as low temperature of ore heap, and achieve the effects of reducing heat loss, improving biological heap leaching efficiency, and improving bacterial concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

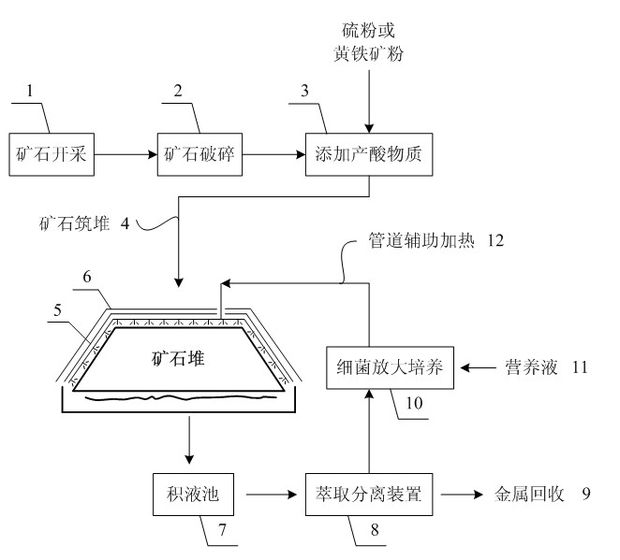

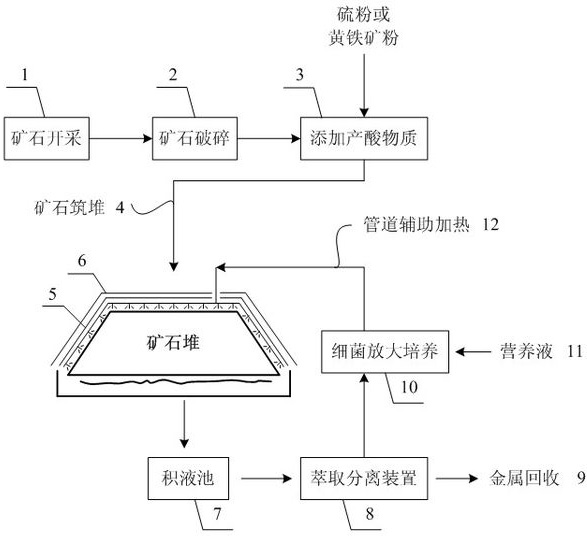

[0032] Such as figure 1 As shown, antifreeze methods for sulfide ore bioleaching piles:

[0033] Firstly, the ore 1 is mined according to a known method, and sent to the crushing operation process 2. In the crushing process, the ore is crushed to a predetermined particle size, usually within 0--50mm.

[0034] The crushed ore is conveyed into the drum, wetted by dilute sulfuric acid with a concentration of 0.1-1.0mol / L3, and mixed with 1-2% of the total mass of the ore. The drum is rolling, and biological oxidation exothermic substances are added during the rolling process, and the nozzle continuously sprays dilute sulfuric acid onto the surface of the ore. Most of the fine ore will adhere to the surface of coarse ore particles or spontaneously bond into group. The ore is transported to the storage yard after being processed by the drum, and is stacked into single or multiple ore piles according to known methods.

[0035] As we all know, it is necessary to level the yard an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com