Liquid heating type metering jet pump in SCR (selective catalytic reduction) system

A SCR system, heating technology, applied in the direction of mechanical equipment, engine components, dispersed particles separation, etc., can solve the problems of SCR system usage limitation, battery life impact, increase wire connection, etc., to save heating devices, facilitate daily maintenance, The effect of improving the utilization rate of energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions in the preferred embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

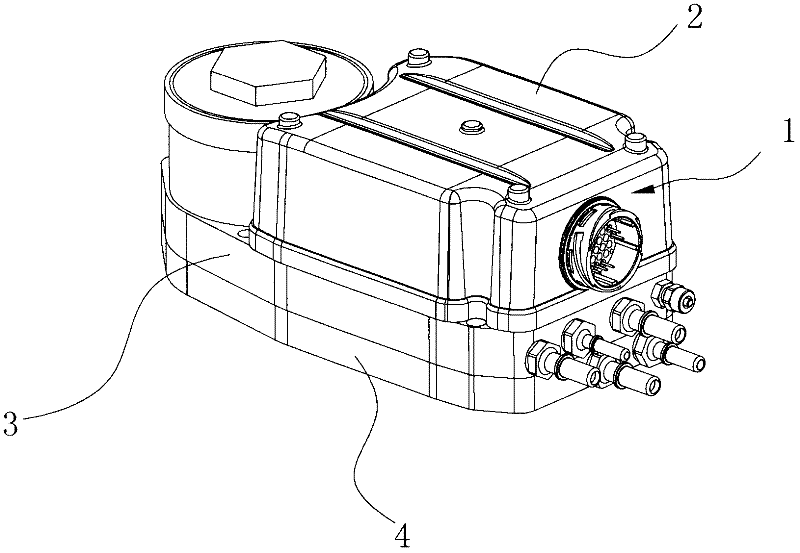

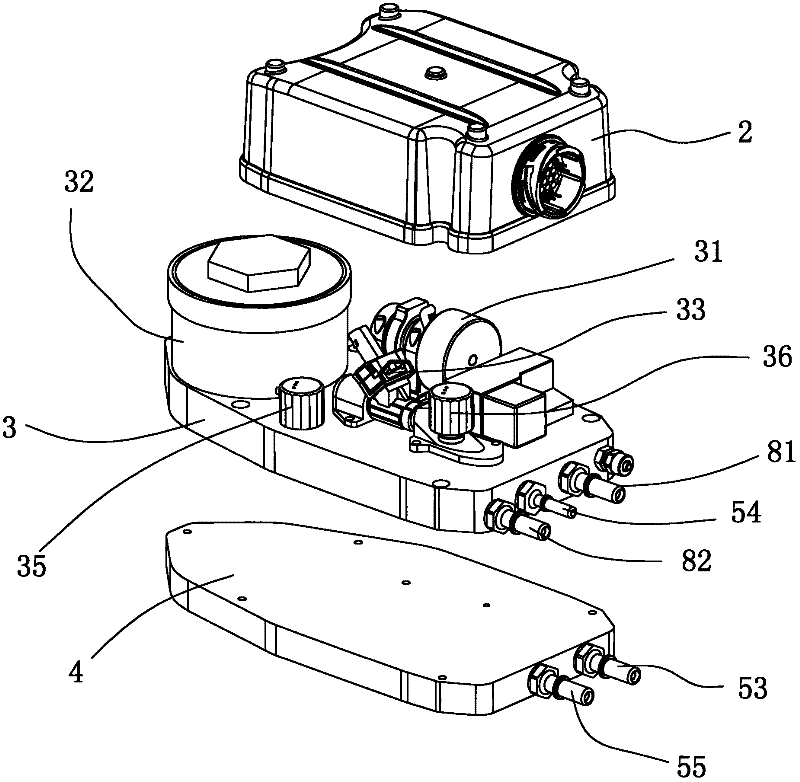

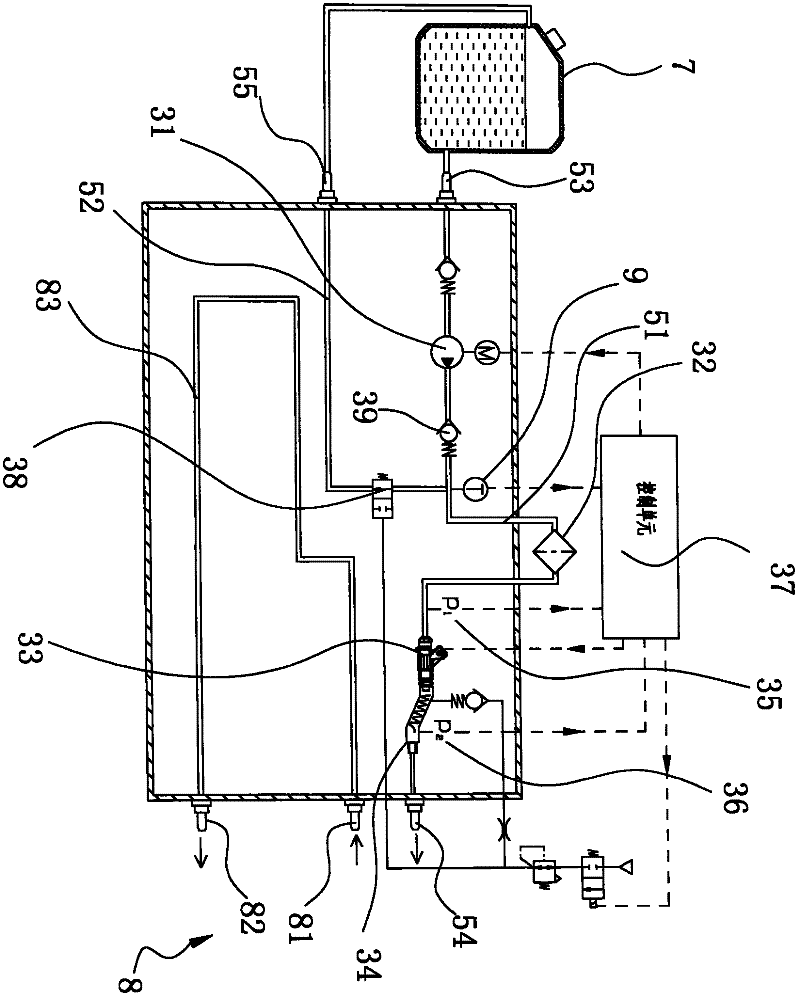

[0036] Such as Figure 1-Figure 6 As shown, the liquid heating metering injection pump in the SCR system of the present invention is used to inject the reducing agent in the SCR system into the exhaust pipe, and it includes a metering injection unit 1 and a water heating unit for heating the metering injection unit 8. The metering injection unit includes a cover body 2, a pump body 3, a base plate 4, a diaphragm pump 31, a filter 32, a metering valve 33, a mixing chamber 34, a first pressure sensor 35, a second pressure sensor 36, and a control unit 37, and the liquid flow channel 5 formed on the pump body for the reducing agent to flow.

[0037] combine figure 1 , figure 2 and image 3 As shown, the cover body 2 is fastened on the pump body 3, forming a closed space wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com