Device and method for drilling tap hole on submerged-arc furnace through oriented plasma

A technology of plasma mine and furnace hole opening, which is applied to furnaces, furnace components, lighting and heating equipment, etc., can solve the problems of long time required for furnace hole opening, high labor intensity, high power consumption, etc., and shorten the time of furnace hole opening , reduce labor intensity, the effect of high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

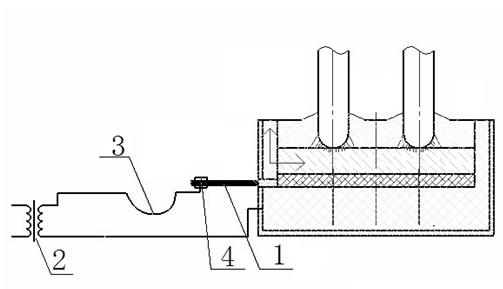

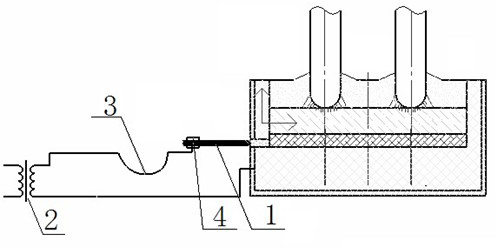

[0017] A furnace opening device for a directional plasma submerged arc furnace, such as figure 1 As shown, it includes carbon rod 1, power supply 2, cable 3, carbon rod clamping and holding mechanism 4, etc., wherein: one end of carbon rod 1 (hereinafter referred to as the clamping operation end) is provided with carbon rod clamping and holding mechanism 4, It is convenient for the operator to operate; the diameter of the carbon rod is 120mm ~ 180mm, and a through hole with a diameter of 6 ~ 16mm is drilled in the center of the carbon rod, and a pipe joint is installed at the end thread of the clamping operation end of the carbon rod. For access to inert gas; the clamping operation end of the carbon rod is connected to the power supply 2 through the cable 3, the power supply can be AC or DC power supply, and the power supply voltage is 50V-240V.

[0018] The present invention also provides a method for opening holes in a directional plasma submerged arc furnace, comprising t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com