Steel cord belt flaw detection system and detection method therewith

A technology of steel wire rope core and tape, applied in the direction of material magnetic variables, etc., can solve the problems of manufacturing trouble, affecting signal processing and analysis, and reducing bearing capacity, and achieve the effects of convenient manufacturing and use, and scientific and reasonable detection methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The system of the present invention consists of a belt conveyor and a monitoring system.

[0026] The present invention will be described in detail below with reference to the accompanying drawings.

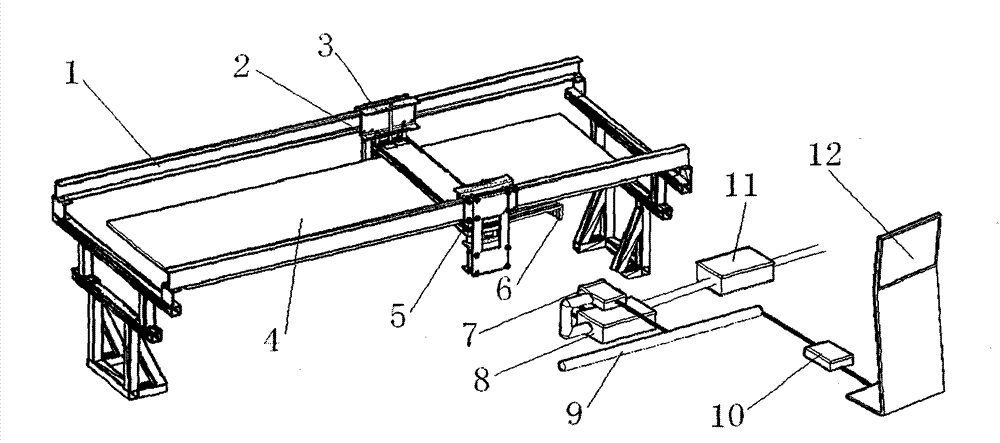

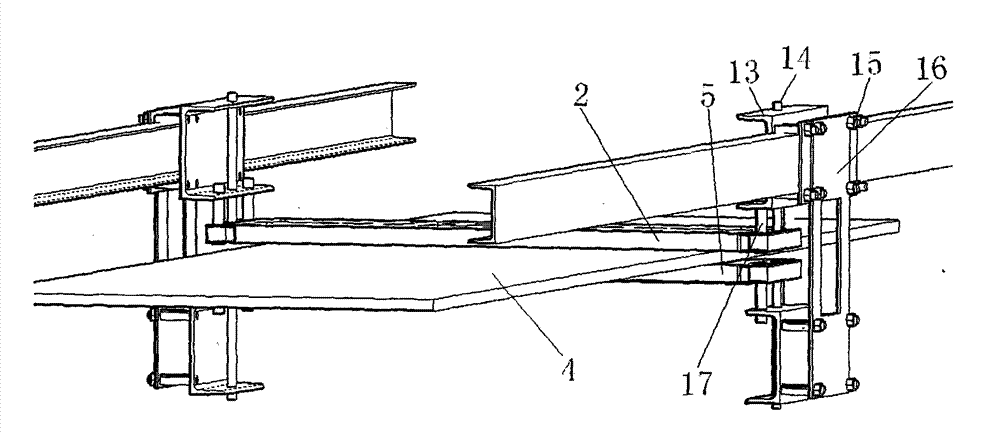

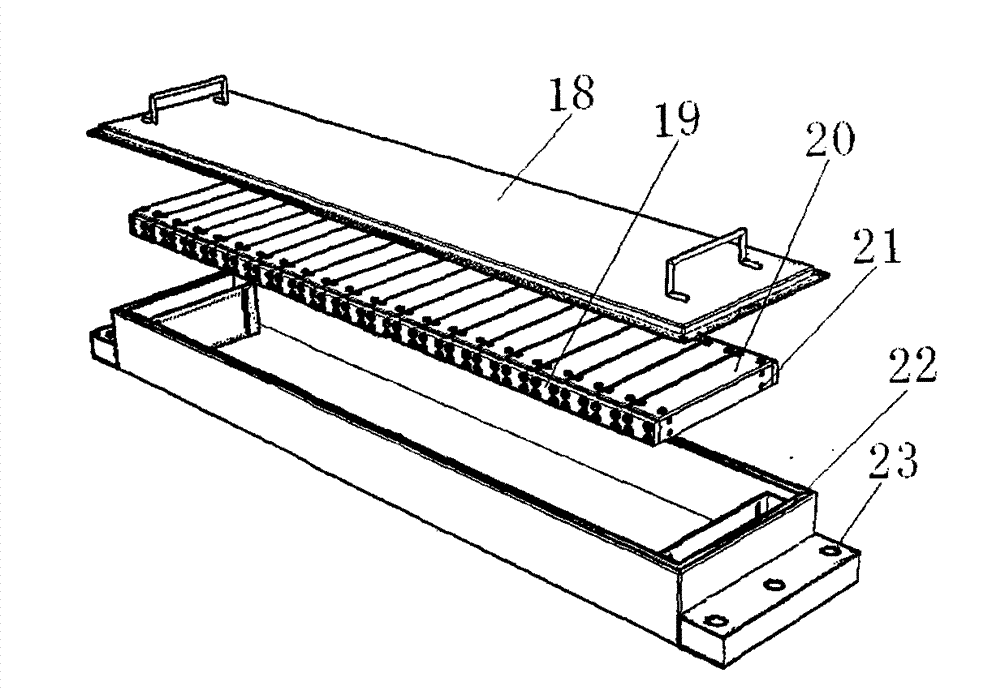

[0027] refer to figure 1 , the magnetizer 2 and the detection sensor 5 are fixed on the belt conveyor 1 through the mounting bracket 3, there is a space for placing the steel wire core tape 4 between the magnetizer 2 and the detection sensor 5, and the detection sensor and the signal processor 8 installed on the belt conveyor pass the detection The signal line 6 is connected, the downhole optical fiber transceiver 7 is connected with the uphole optical fiber transceiver 10 through the communication optical cable 9, the electrical signal converted by the uphole optical fiber transceiver enters the well computer 12, and the signal processor 8 is connected to the belt conveyor operation controller 11. The optical fiber transceivers in the upper and lower wells use the existi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com