Method for testing tar amount of cigarettes treated differently

A technology of testing methods and processing methods, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as the influence of cigarette burning, the impact of cigarette tar testing, and differences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

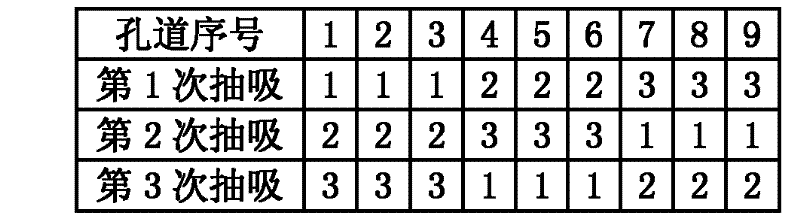

[0061] Formulation of 3-treatment suction scheme for 20-hole smoking machine

[0062] The number of holes in the smoking machine is 20, the number of cigarettes to be processed is 3, 20 divided by 3 equals 6 and 2, rounded down to 6, 3×6=18, only the first 18 holes are used to formulate the smoking plan. Cigarettes with 3 treatments in each puff, each treatment occupying 6 holes.

[0063] During the first puff, cigarettes with the first treatment are placed in holes 1-6, cigarettes with the second treatment are set in holes 7-12, and cigarettes with the third treatment are set in holes 13-18; , cigarettes with the second treatment in 1-6 holes (the treatment number of cigarettes with the first b holes is equal to the number of puffs), cigarettes with the third treatment in 7-12 holes (the number of cigarettes with the next b holes is equal to the number of puffs), Add 1 to the number of treatments set for the first b tunnels), and set the cigarettes of the first treatment in ...

Embodiment 2

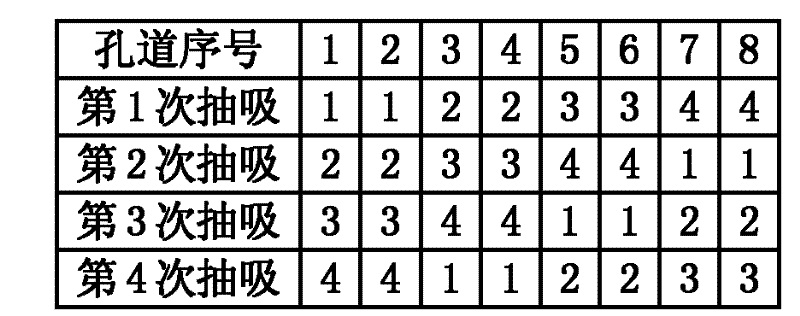

[0066] Comparative Analysis of Tar Tests on Three Kinds of Treated Cigarettes Using a 10-hole Smoking Machine

[0067] ① Selected smoking plan and cigarette smoking

[0068] There are 3 kinds of cigarettes processed by different processes, according to figure 1 Cigarette smoking is carried out according to the scheme, and each hole continuously sucks 4 cigarettes of the same treatment in each puff (every 4 cigarettes share a filter filter); in each puff, each treatment cigarette Occupying 3 holes, 12 cigarettes were smoked for each treatment; 9 holes were shared, and a total of 36 cigarettes were smoked in each smoking experiment. After smoking according to the selected scheme, the total particulate matter of cigarettes with different puffing times, different holes and different treatments is obtained. The nicotine and moisture of cigarettes with different puffing times, different holes and different treatments are measured, and the different puffing times and different hole...

Embodiment 3

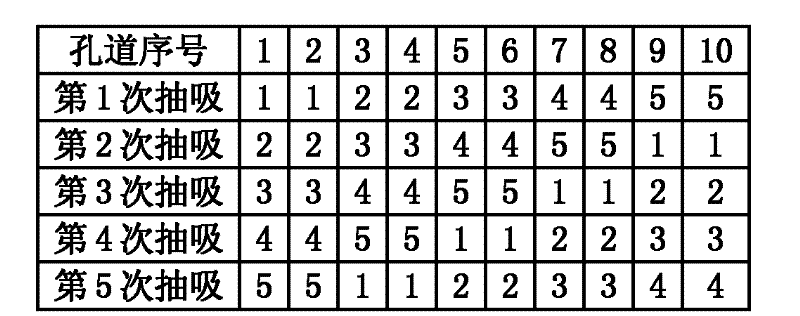

[0126] Comparative analysis of tar test on five processed cigarettes using a 20-hole smoking machine

[0127] In order to study the effectiveness of cigarette coke reducers, different amounts of coke reducers were added to the same kind of cigarettes. , the newly made cigarettes are referred to as the first treated cigarettes, the second treated cigarettes, the third treated cigarettes, the fourth treated cigarettes, and the fifth treated cigarettes. according to Figure 6 Cigarette smoking is carried out according to the scheme, in each puff, 4 cigarettes of the same treatment are continuously sucked in each puff, and the total particulate matter of cigarettes with different puff times, different puffs and different treatments are obtained after smoking, and the different puffs are measured. The nicotine and moisture of cigarettes with different puffs and different treatments in the number of puffs can be used to obtain the tar content of cigarettes with different puffs and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com