Shallow slot negative bevel terminal structure and preparation method thereof

A terminal structure and bevel technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of large chip area and poor stability, and achieve the effect of reducing process cost and taking into account stability and mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

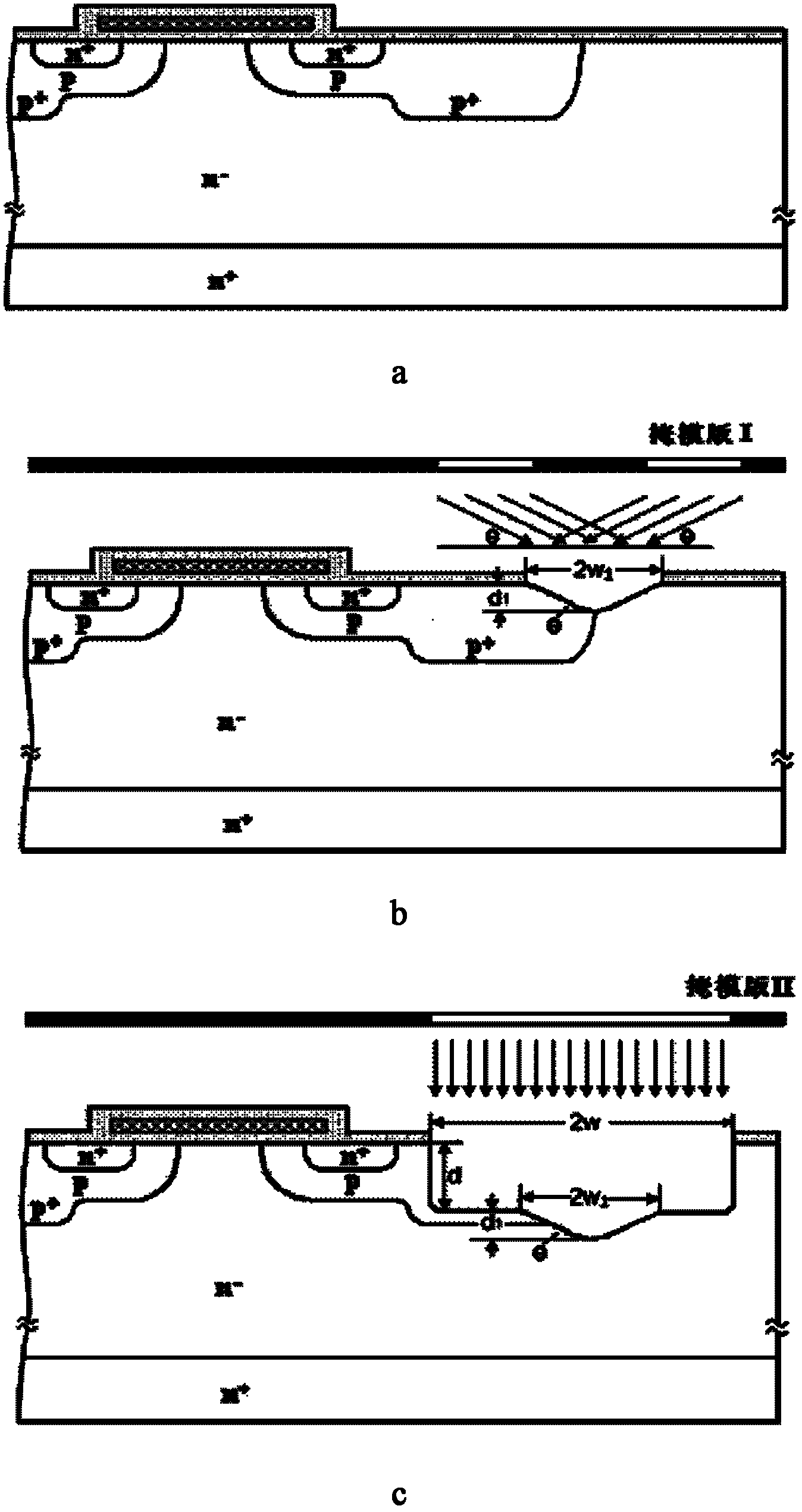

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0018] refer to figure 1 d, the shallow groove negative bevel terminal structure suitable for power MOS devices of the present invention is that the center of the chip is the active area, the periphery is the terminal area, and the common n of the active area and the terminal area + The bottom of the substrate is the drain D of the device, n + n - drift zone;

[0019] n in the active area - There are multiple cells in the drift area, and the bottom of each cell is p + well area, p + Above the well region is the p-body region, and the n-body region is set in the p-body region. + source area, n + Above the source region is the source electrode S, and the source electrode S will be n + The source region is short-circuited to the p-body region; a polysilicon gate G is provided between two adjacent source electrodes S, and a gate oxide lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com