Magnetic slot wedge and preparation process and application thereof

A preparation process and technology of magnetic slot wedges, which are used in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve the problems of inapplicability of magnetic slot wedges, etc., and achieve the effects of reliable fixed coil, improved performance, and reduced surface loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

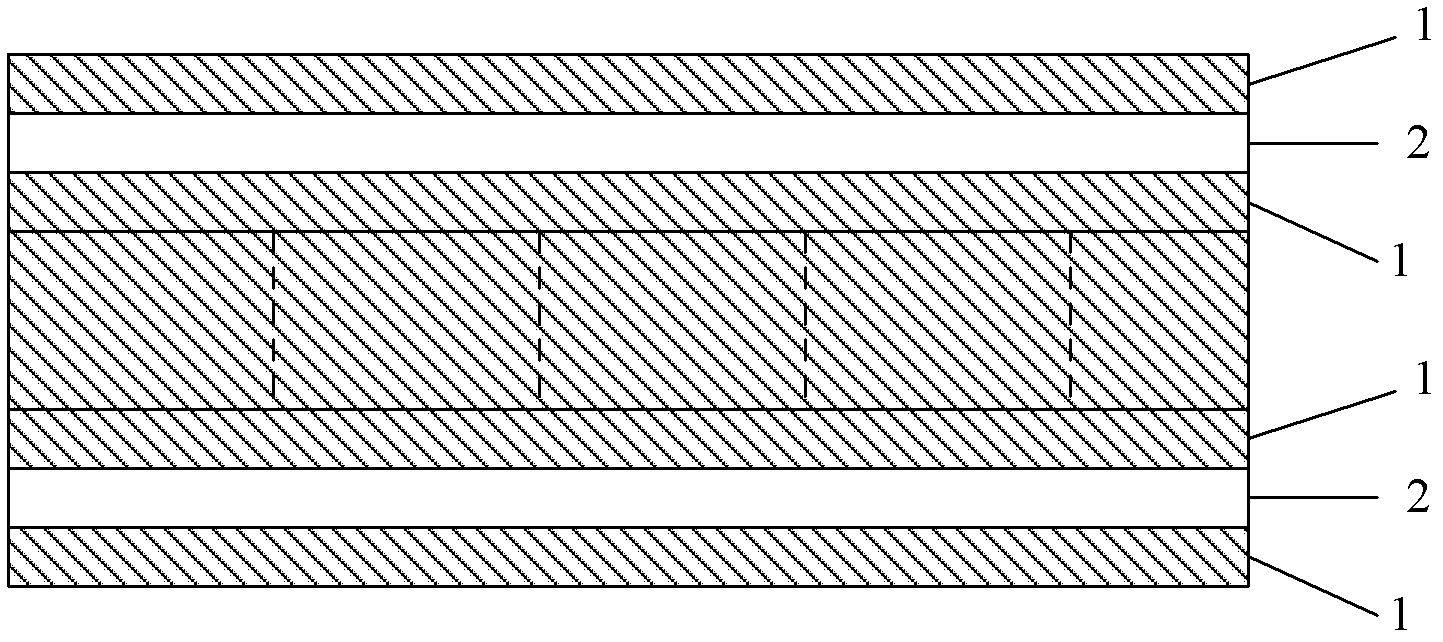

[0036] Embodiment 1 Magnetic slot wedge

[0037] 1. Glue matching:

[0038] (1) Iron powder is soaked in alcohol for 30 minutes;

[0039] (2) Add phenolic resin, and stir fully, so that the iron powder does not unite and gather, and when the color is uniform, the stirring is completed to obtain a paste;

[0040] (3) After laying the glass fibers on the surface of the paste, dipping, try not to wrinkle, to ensure that the grid structure in the glass fiber cloth is not damaged, and the mechanical strength of the made slot wedge is high and similar; Then put it on the tray, spread it slowly, and volatilize for 4 hours to completely volatilize the alcohol and water; put it in an oven, keep it warm at 80°C for 20 minutes, and then cool it to obtain a blank with rubber; the weight of iron powder, phenolic resin and glass fiber cloth The ratio is 90:5:5;

[0041] 2. Molding

[0042] (1) After the mold is heated to 100°C, a layer of release agent is applied, and the rubber-contain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com