Electric heating element and manufacturing method thereof

A technology for heating elements and manufacturing methods, which is applied in the field of electric heating elements and its manufacturing, can solve the problems of unstable quality of carbon fiber products, weak research and development foundation, and substandard performance, and achieve the effects of eliminating human fatigue, low cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

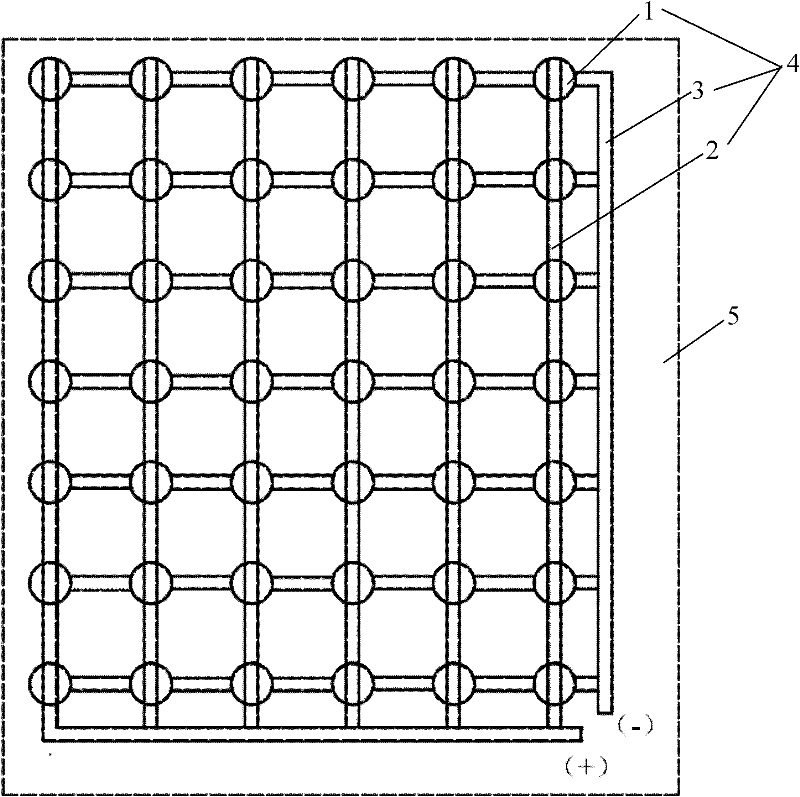

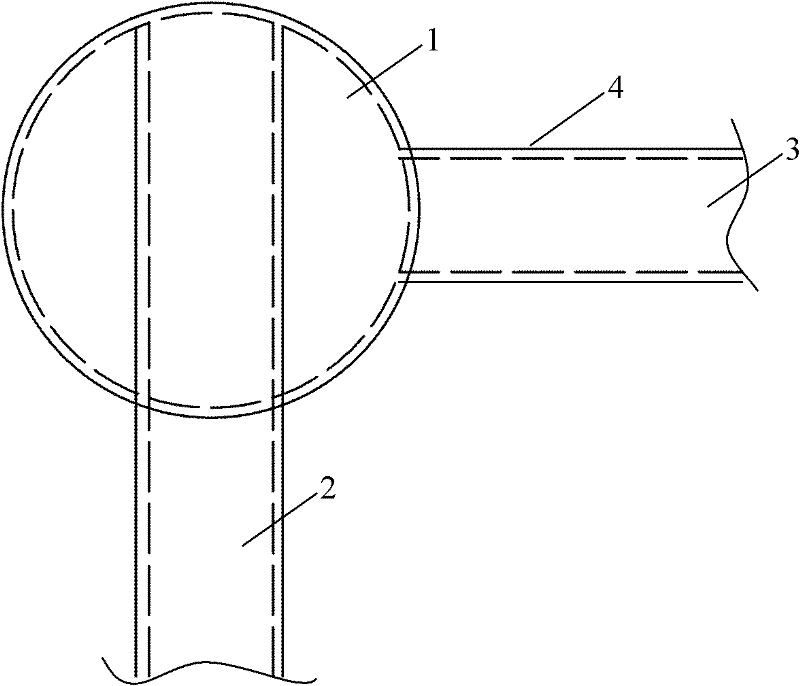

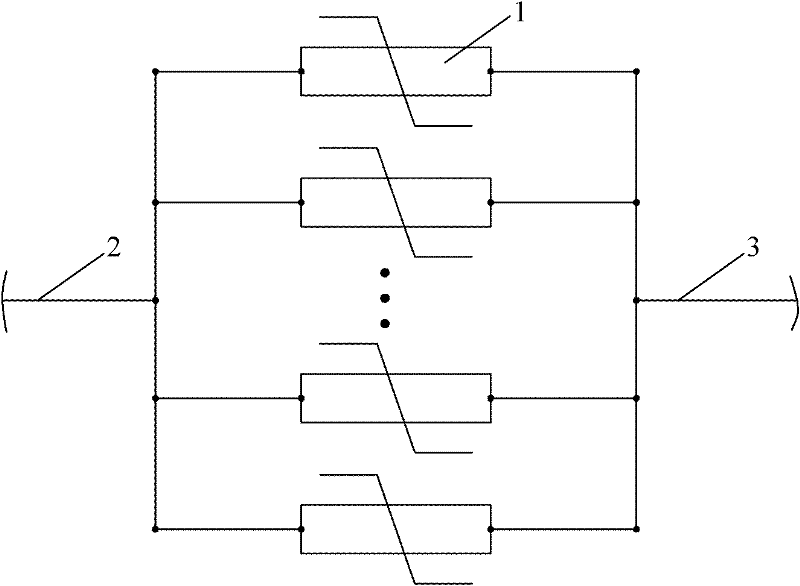

[0040] See Figure 1~4 as shown, Figure 1~4 What is shown is a specific embodiment of the electric heating element of the present invention, which is a relatively simple and common design scheme of a network structure composed of PTC thermistors 1 .

[0041]The thermally conductive positive electrode 2 and the thermally conductive negative electrode 3 are closely attached to the upper and lower surfaces of the PTC thermistor 1, and the two are only connected through the PTC thermistor 1; the thermally conductive positive electrode 2, the thermally conductive negative electrode 3 and multiple PTC thermistors The combination of sensitive resistors 1 (m rows×n columns of PTC thermistors 1) constitutes a polygonal network structure, and the thermally and electrically conductive positive electrodes 2 and thermally conductive and conductive negative electrodes 3 are arranged parallel to each other and criss-crossed. figure 1 and Figure 4 It can be seen that the thermally conduct...

Embodiment 2

[0052] See Figure 5 as shown, Figure 5 Shown is the electric heating heating element made into the electric heating cushion. Designed to use a DC power supply: output 12VDC, maximum current: 2A, select a Curie temperature of 55°C, R25 resistance of 500±50Ω, and a withstand voltage of more than 500V. The ceramic positive temperature coefficient thermistor is made according to the aforementioned method. Figure 5 Shown is a network structure composed of 9×7 PTC thermistors 1; the initial heating power is 18W, and the actual measurement shows that the continuous heating of the electric heating cushion takes 135 seconds from normal temperature to the thermal equilibrium temperature, and the temperature at thermal equilibrium is 49.5°C, and the heat is generated at this time The power is 9.3W.

[0053] The specific manufacturing method is as follows:

[0054] (1) Select the appropriate PTC thermistor 1 according to the needs: the Curie temperature is 55°C, the R25 resistance i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure capacity | aaaaa | aaaaa |

| Curie temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com