Defoliant

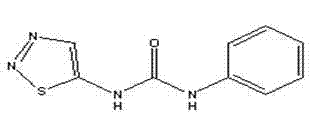

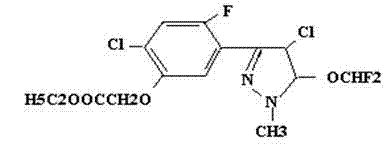

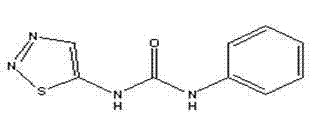

A technology of defoliant and thiadizuron, which is applied in biocides, animal repellents, plant growth regulators, etc., to achieve the effect of reducing dosage and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1: 10% thiadizuron + 1% baconate suspending agent

[0049] Thidiazuron 10%

[0050] Bacao Ling 1%

[0051] Sodium methylnaphthalenesulfonate formaldehyde condensate 10%

[0052] Xanthan Gum 1%

[0053] Bentonite 1%

[0054] Glycerol 5%

[0055] Water to make up to 100%

[0056] Mix active components, dispersant, wetting agent, water and other components according to the ratio of the formula, and grind and / or high-speed shear to obtain 10% thiadizuron + 1% tyrazolin suspension concentrate.

[0057]

Embodiment 2

[0058] Example 2 30% thiadizuron + 0.15% bacuron wettable powder

[0059] Thidiazuron 30%

[0060] Ba Cao Ling 0.15%

[0061] Sodium Lauryl Sulfate 2%

[0062] Sodium lignosulfonate 5%

[0063] Silica 10%

[0064] Kaolin supplemented to 100%

[0065] The above components were mixed in proportion, ground and pulverized to prepare wettable powder of 30% thiadizuron + 0.15% bacuron.

[0066]

Embodiment 3

[0067] Example 3 50% thiadizuron + 0.1% bacuron emulsion in water

[0068] Thidiazuron 50%

[0069] Ba Cao Ling 0.1%

[0070] N-Methylpyrrolidone 15%

[0071] Calcium dodecylbenzenesulfonate 5%

[0072] Farm milk 600# 5%

[0073] Water to make up to 100%

[0074] Add the original drug, solvent, and emulsifier together to dissolve into a uniform oil phase; mix the water-soluble components with water to obtain a water phase; mix the oil phase with the water phase under high-speed stirring to obtain a 50% thiamine Benuron + 0.1% Bacaoling water emulsion.

[0075]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com