A product for preventing and treating cervical lesions and wounds

A technology for cervical lesions and trauma, which is applied in the field of products for the prevention and treatment of cervical lesions and traumas. It can solve the problems of inability to treat cervical lesions and traumas, incomplete coverage of treatment parts, and slow treatment effects, so as to shorten the recovery period of surgery, Promoting normal growth and avoiding the effect of surgical treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

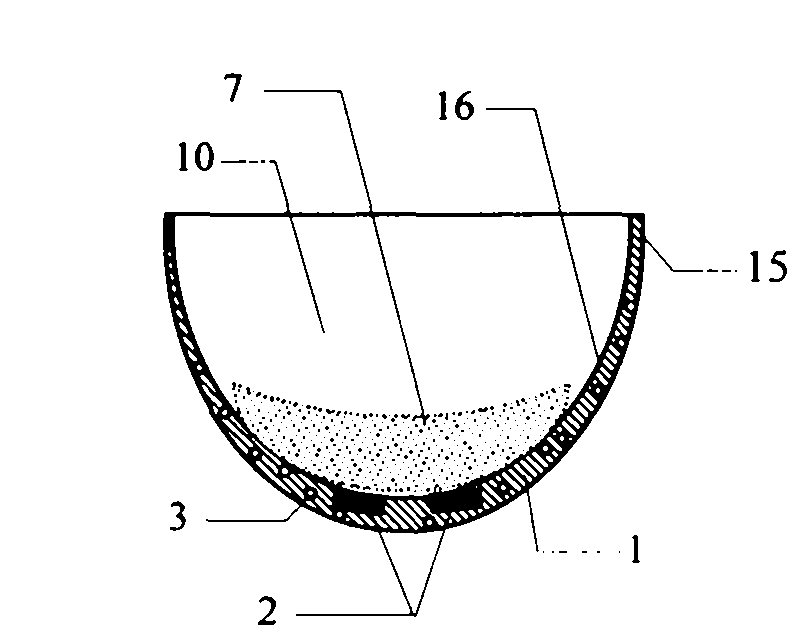

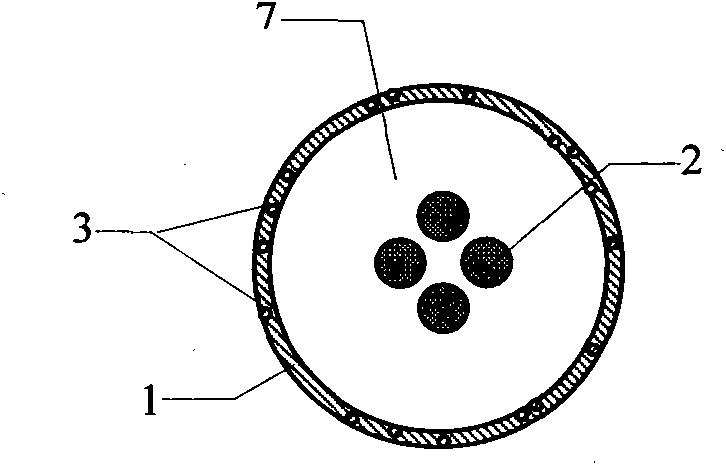

[0105] see figure 1 , figure 2, Fig. 28, the present embodiment provides a kind of product of prevention and treatment of cervical lesions and wounds, the manufacturing process is: prepare 7% polyvinyl alcohol, 2% sodium alginate, 2% far-infrared ray ceramic nanopowder, the balance is to remove The mixed slurry of ionic water is stirred evenly, and after vacuum defoaming, the slurry is injected into the mold, dried at 30°C-40°C, and thermally cross-linked and cured in an oven at 60°C for 40 minutes to form the sticking wall 1, There is a formed groove on the bottom of the sticking wall 1, and four pieces of silver-plated NdFeB circular magnets are embedded in the groove, the diameter of the magnets is 3mm, and the thickness is 1mm. The diameter of the opening of the application wall 1 is 26mm, the depth of the cavity 10 surrounded by the application wall 1 is 16mm, the wall thickness at the opening of the application wall 1 is 1mm, and gradually thickens towards the bottom, ...

Embodiment 2

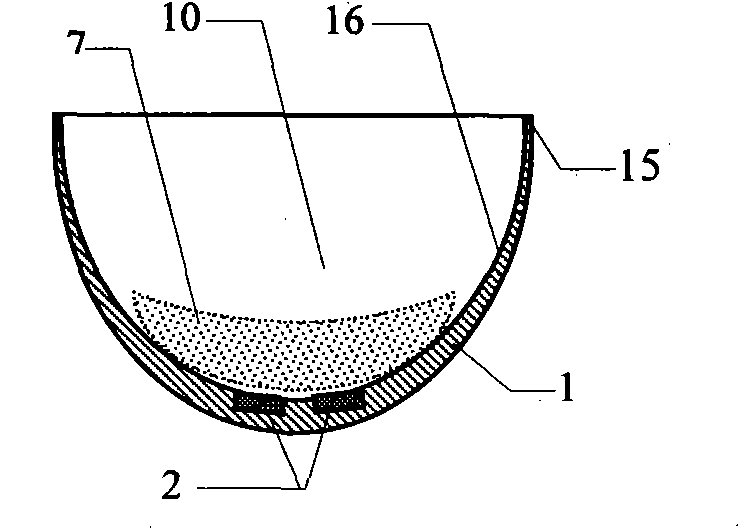

[0107] see image 3 , Figure 28, the present embodiment provides a product for preventing and treating cervical lesions and wounds, the production process is: prepare 7% polyvinyl alcohol, 2% sodium alginate, 0.01% sodium selenite, and the balance is deionized The water mixed slurry is stirred evenly, and after vacuum defoaming, the slurry is poured into a mold, dried at 30°C-40°C, and thermally cross-linked and cured in an oven at 60°C for 40 minutes to form the sticking wall 1 . There is a formed groove on the bottom of the sticking wall 1, and four pieces of silver-plated NdFeB circular magnets (that is, the magnetic material 2) are embedded in the grooves. The diameter of the magnets is 3mm and the thickness is 1mm. The diameter of the opening of the application wall 1 is 26mm, the depth of the cavity 10 surrounded by the application wall 1 is 16mm, the wall thickness at the opening of the application wall 1 is 1mm, and gradually thickens towards the bottom, and the wall t...

Embodiment 3

[0109] see Figure 4 , The present embodiment provides a product for preventing and treating cervical lesions and wounds. The manufacturing process is: using medical liquid silicone rubber raw materials, injecting molding to stick to the wall 1 . The diameter of the opening of the application wall 1 is 26mm, the depth of the cavity 10 surrounded by the application wall 1 is 16mm, the wall thickness at the opening of the application wall 1 is 1mm, and gradually thickens towards the bottom, and reaches 1.7mm at the bottom . The bottom of the application wall 1 has a drain hole 12 with a diameter of 3 mm, and a coating 5 is coated on the inner surface 16 of the application wall. The thickness of the coating 5 is less than 5 mm, preferably 0.1-1 mm.

[0110] Wherein the preparation process of coating coating 5 is: the preparation process of 6% polyvinyl alcohol, 0.3% methyl hydroxyethyl cellulose, 0.01% sodium selenite, 3% tourmaline powder, 1% nanometer zinc oxide powder, The b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Opening diameter | aaaaa | aaaaa |

| Surface diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com