A submerged hollow fiber membrane module

A fiber membrane and membrane module technology, applied in the field of hollow fiber membrane modules, can solve the problems of high cost of replacement, inconvenient disassembly and assembly, poor hydraulic conditions, etc., achieve independent disassembly and installation, easy installation and disassembly, operation and maintenance convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

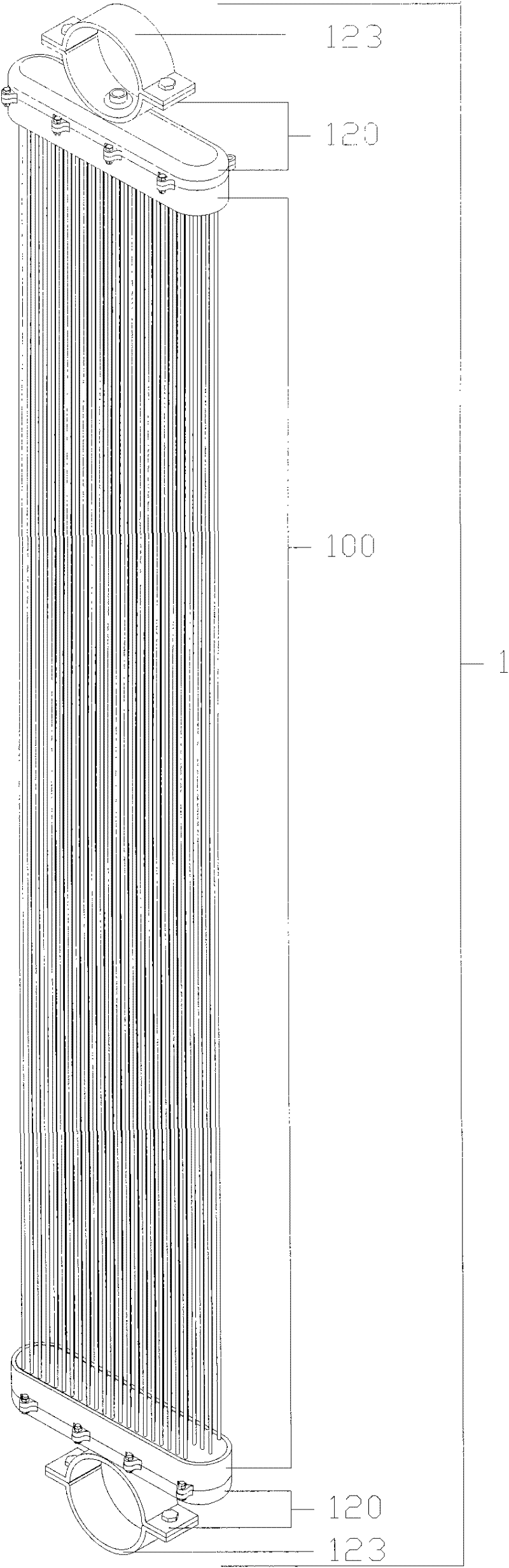

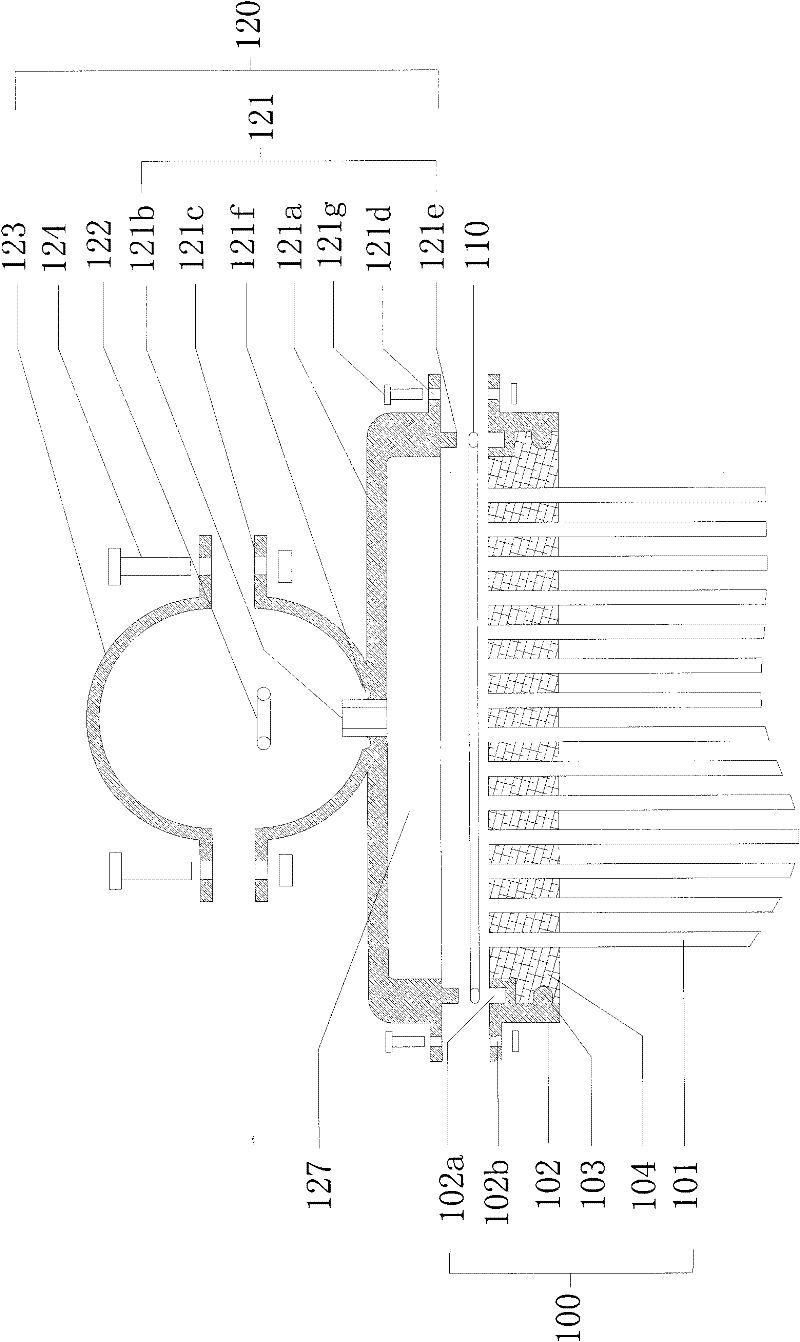

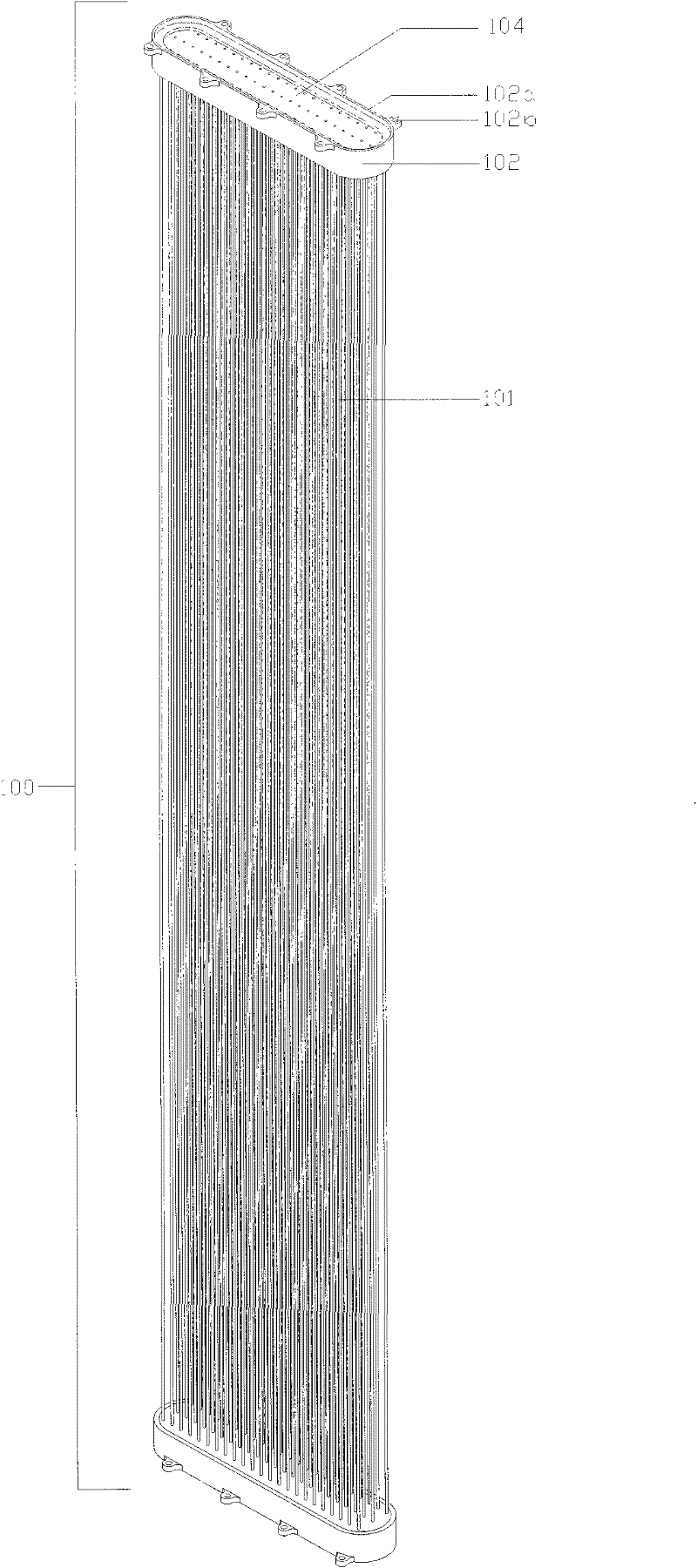

[0017]This embodiment describes the basic form of a submerged membrane element according to the present invention and the basic form of the membrane module formed by it, as shown in Figures 1, 2, 3 and 5. The specific implementation of this example can be completed in three steps. In the first step, the hollow fiber module (100) is fabricated. The specific method is to encapsulate the two ends of several hollow fiber membranes (101) with the same length and arranged in parallel in a curtain shape with resin (104) in the membrane package groove (102) at one time respectively, and wait for the resin (104) ) after curing, use a special tool to cut the resin (104) at one end of the sealing groove (102a) of the membrane filament packaging groove (102) flat, and expose the inner cavity of one end of the membrane filament encapsulated thereon to form a whole, That is the hollow fiber module (100). In the second step, the hollow fiber module (100) and the water collecting part (120)...

Embodiment 2

[0020] This embodiment describes a membrane module composed of two membrane columns composed of submerged membrane elements of the present invention, as shown in Figures 1, 2, 3 and 6. The specific implementation of this example can be completed in three steps. In the first step, the hollow fiber module (100) is fabricated. The specific method is to encapsulate the two ends of several hollow fiber membranes (101) with the same length and arranged in parallel in a curtain shape with resin (104) in the membrane package groove (102) at one time respectively, and wait for the resin (104) ) after curing, use a special tool to cut the resin (104) at one end of the sealing groove (102a) of the membrane filament packaging groove (102) flat, and expose the inner cavity of one end of the membrane filament encapsulated thereon, forming a whole , namely the hollow fiber module (100). In the second step, the hollow fiber module (100) and the water collecting part (120) are assembled toge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com