High precision ultrasonic double sheet detector

An ultrasonic and detector technology, applied in the field of high-precision ultrasonic double-sheet detectors, to achieve the effect of ensuring stability, reducing costs, and ensuring rapidity

- Summary

- Abstract

- Description

- Claims

- Application Information

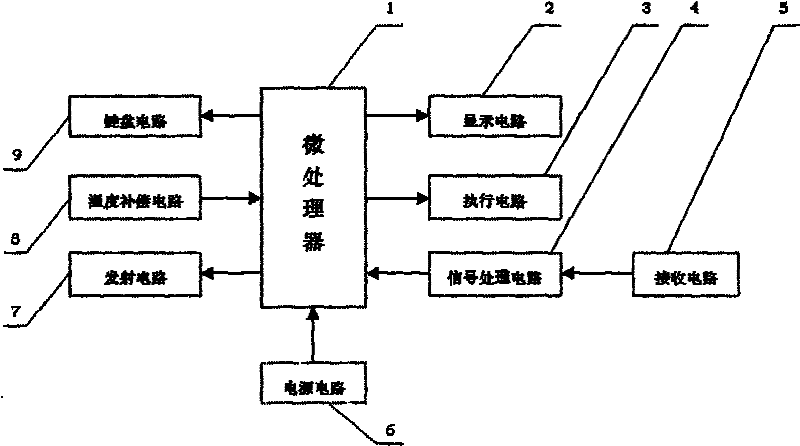

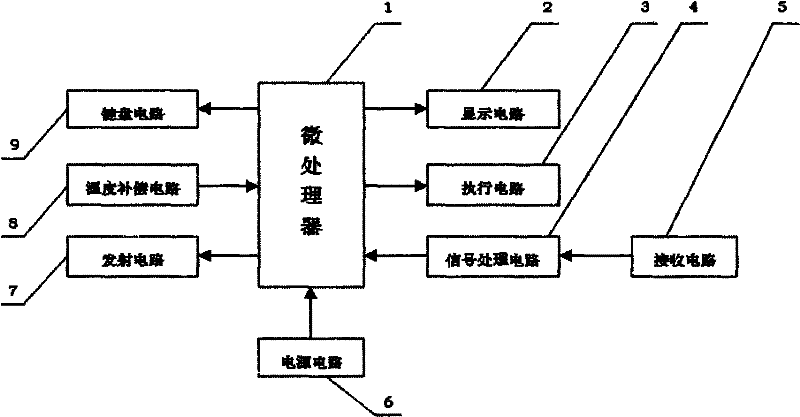

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

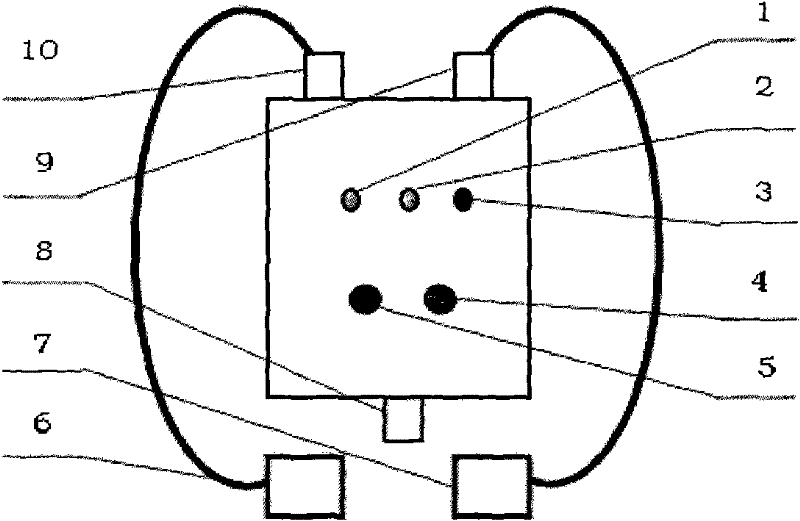

[0030] When installing this high-precision ultrasonic double-sheet detection, ensure that the surface of the two probes is at a distance of 25mm to 35mm. After the installation is completed, first calibrate the paper to be tested, and specifically place the paper in the middle between the probes (work and calibration) The position of the paper is the same), press the calibration key in the keyboard circuit 9, and all the light-emitting diodes in the display circuit 2 will light up, indicating that the calibration is completed, and then the detector can perform detection work; when the ambient temperature changes, the system will be based on The temperature value replaces the corresponding correction value offset, thereby realizing temperature compensation. The selected modules are:

[0031] Microprocessor 1 adopts the high-performance, low-power system-on-chip CC2430 launched by Chipcon. The core clock of this microprocessor can run at 32MHz, which provides a guarantee for hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com