C2 front-end hydrogenation catalyst containing carrier with two peaks pore size distribution and preparation method

A pore size distribution and catalyst technology, which is applied in the field of carbon dioxide pre-hydrogenation catalysts and its preparation, can solve the problems of unsuitable specific surface and pore size distribution, low dispersion of catalyst active components, high acidity of catalyst surface, etc., to improve resistance to heavy metals Poisoning ability, low surface acidity, effect of improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

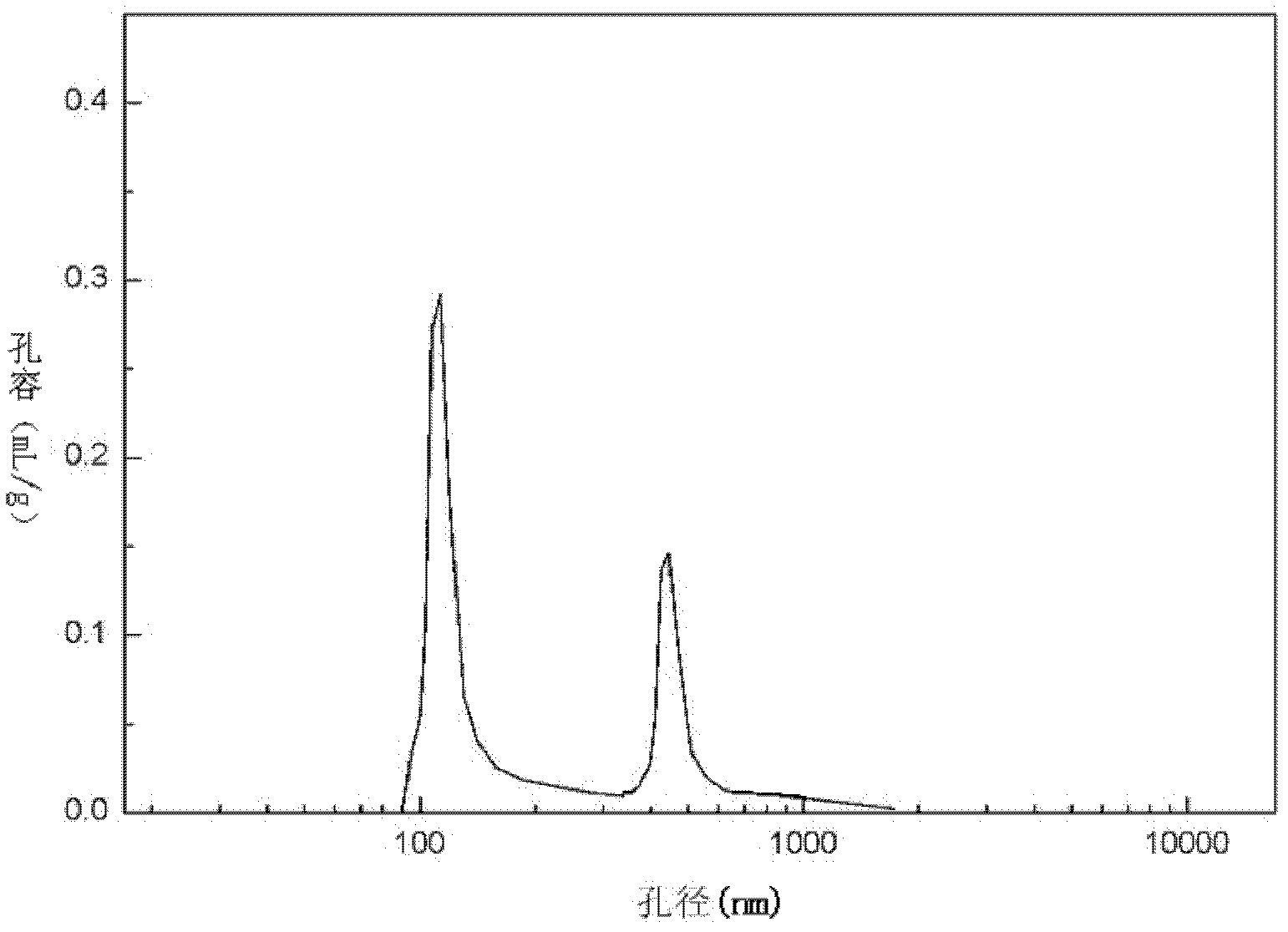

[0046] With stirring, containing NaAlO 2 The solution was neutralized with NaOH solution at 50°C, the hydroxide co-precipitated, stirred for 10 hours to make the hydroxide form uniform fine particles, filtered and washed with distilled water to remove Na + and Cl - ions, adding 7.65% citric acid as a pore-expanding agent, kneading and extruding to make a Φ4mm strip, drying at 120°C for 4 hours and then calcining at 1200°C for 5 hours to obtain an alumina macroporous carrier. Among them, the bulk density is 0.92g / ml, the pore volume is 0.432ml / g, and the specific surface area is 22.4m 2 / g, the carrier has a bimodal pore size distribution at 120nm and 450nm, with an average pore size of 190nm. The pore size distribution of the carrier is as follows: 1% for less than 10nm; 73.30% for 10-200nm; 25.5% for pore size greater than 200nm but less than or equal to 1000nm; 0.2% for pore size greater than 1000nm. The carrier pore size distribution diagram is detailed in figure 1 .

Embodiment 2

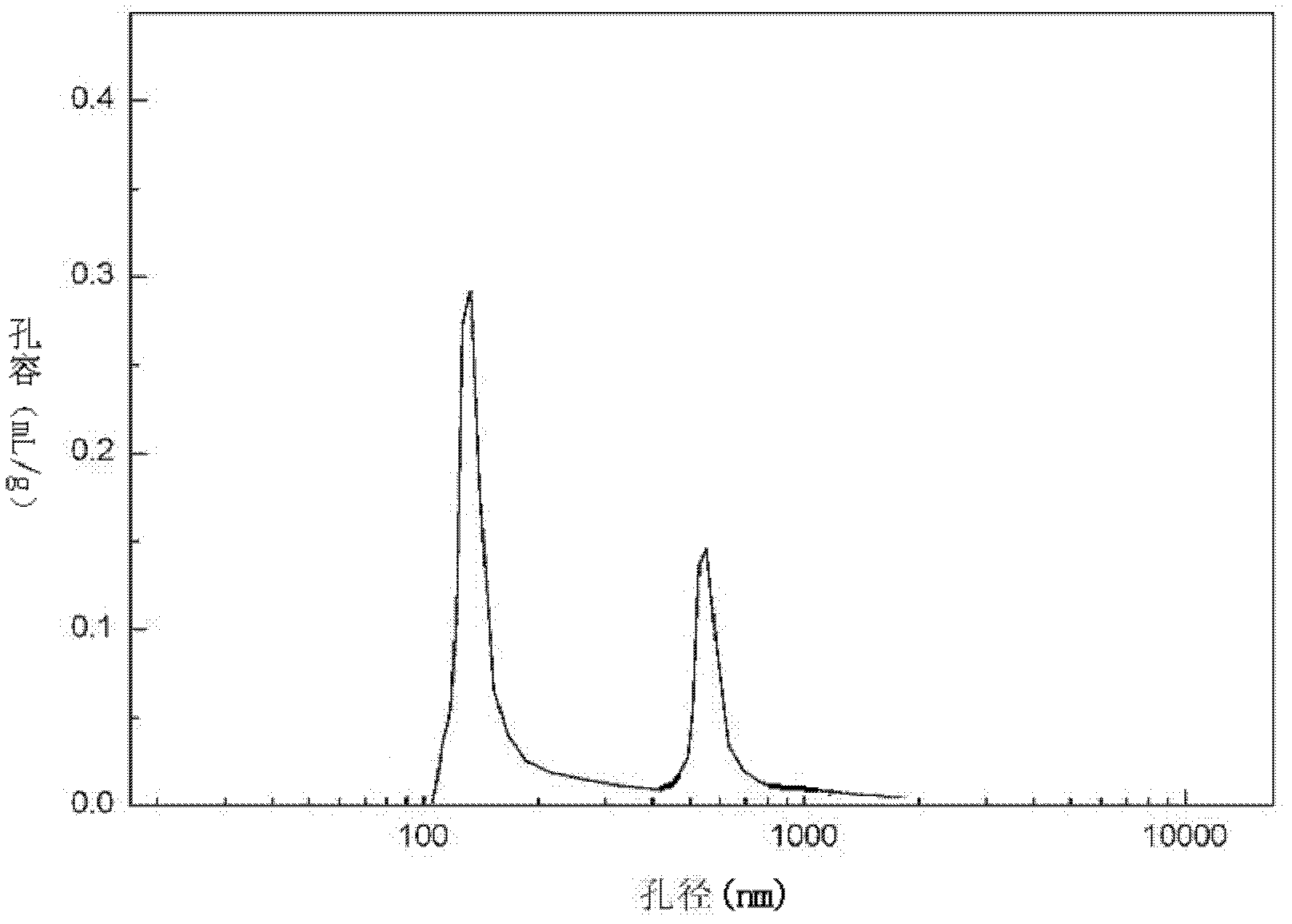

[0048] 850g of alumina, 20g of citric acid and 30g of carbon black were stirred in a mechanical stirrer, extruded into strips of Φ4.2mm, dried at 110°C for 5 hours, and then calcined at 1250°C for 4 hours to obtain an alumina carrier. The pore volume is 0.389ml / g, the bulk density is 0.97g / ml, and the specific surface area is 13.1m 2 / g; the carrier has a bimodal pore size distribution at 155nm and 570nm, with an average pore size of 260nm; the carrier pore size distribution is as follows: 0% for less than 10nm; 73.16% for 10-200nm; 0.18% at 1000nm. The carrier pore size distribution diagram is detailed in figure 2 .

Embodiment 3

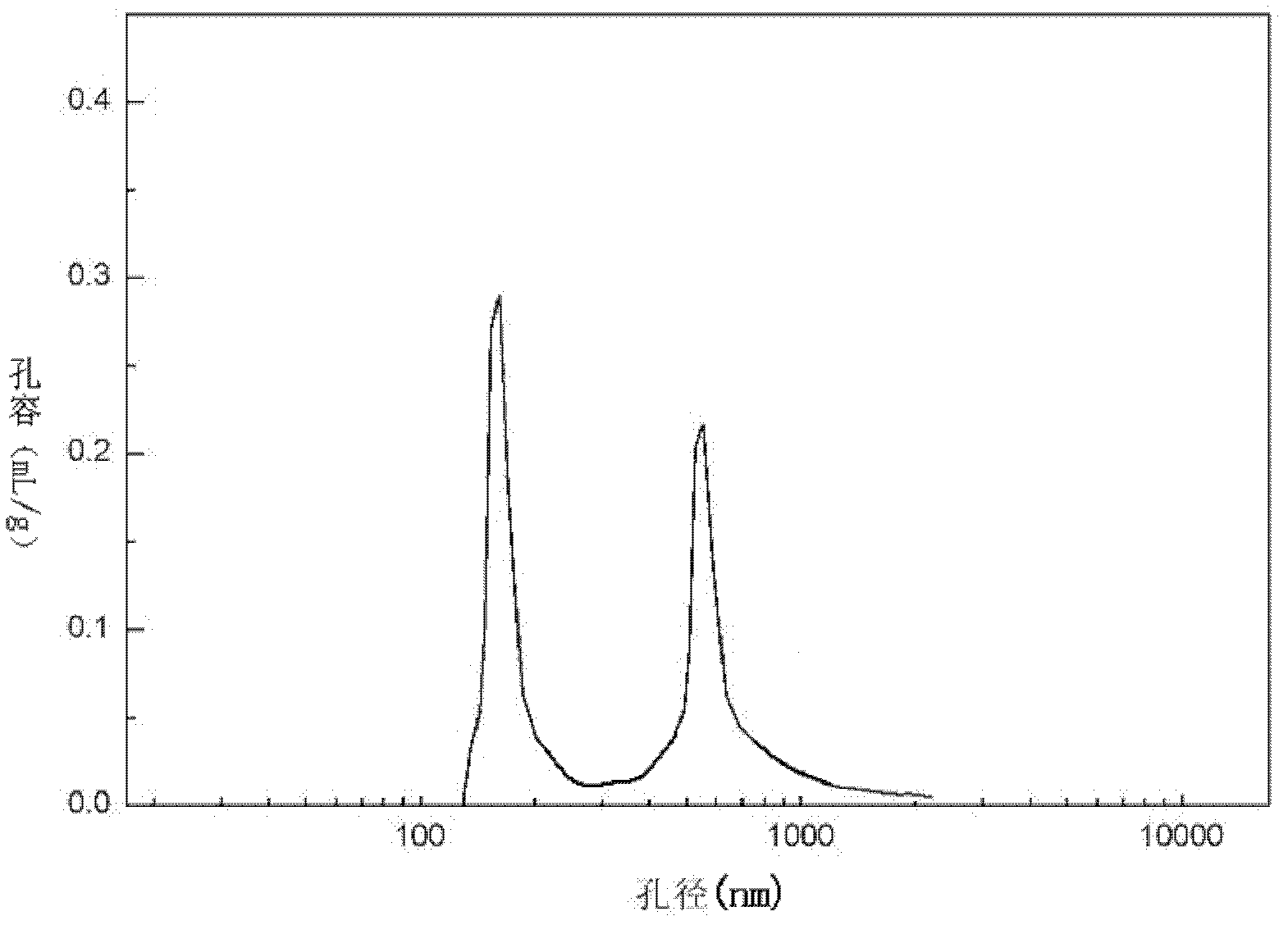

[0050] Under stirring, containing 1000g NaAlO 2 The solution was neutralized with KOH solution at 50°C, the aluminum-titanium hydroxide co-precipitated, stirred for 10 hours to make the aluminum-titanium hydroxide form uniform fine particles, and the product was filtered and washed with deionized distilled water to remove Na + and Cl - ions, adding 15% polyvinyl alcohol as a pore-expanding agent, rolling the ball after kneading, drying at 130°C for 2h and then roasting at 1350°C for 6 hours to obtain α-Al 2 o 3 The carrier has a bulk density of 1.05g / ml, a pore volume of 0.307ml / g, and a specific surface area of 6.5m 2 / g, the carrier has a bimodal pore size distribution at 175nm and 580nm, with an average pore size of 280nm. The pore size distribution of the carrier is as follows: 0% for less than 10nm; 68.50% for 10-200nm; 31.36% for pore size greater than 200nm but less than or equal to 1000nm; 0.14% for pore size greater than 1000nm. The carrier pore size distributio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com