Preparation method of 1,1,1,5,5,5-hexafluoro acetylacetone

A technology of hexafluoroacetylacetone and trifluoroacetoacetate, which is applied in the field of fluorine compound preparation, can solve the problems of environmental pollution, complicated process, and high production cost, and achieve the effects of less environmental pollution, simple process, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

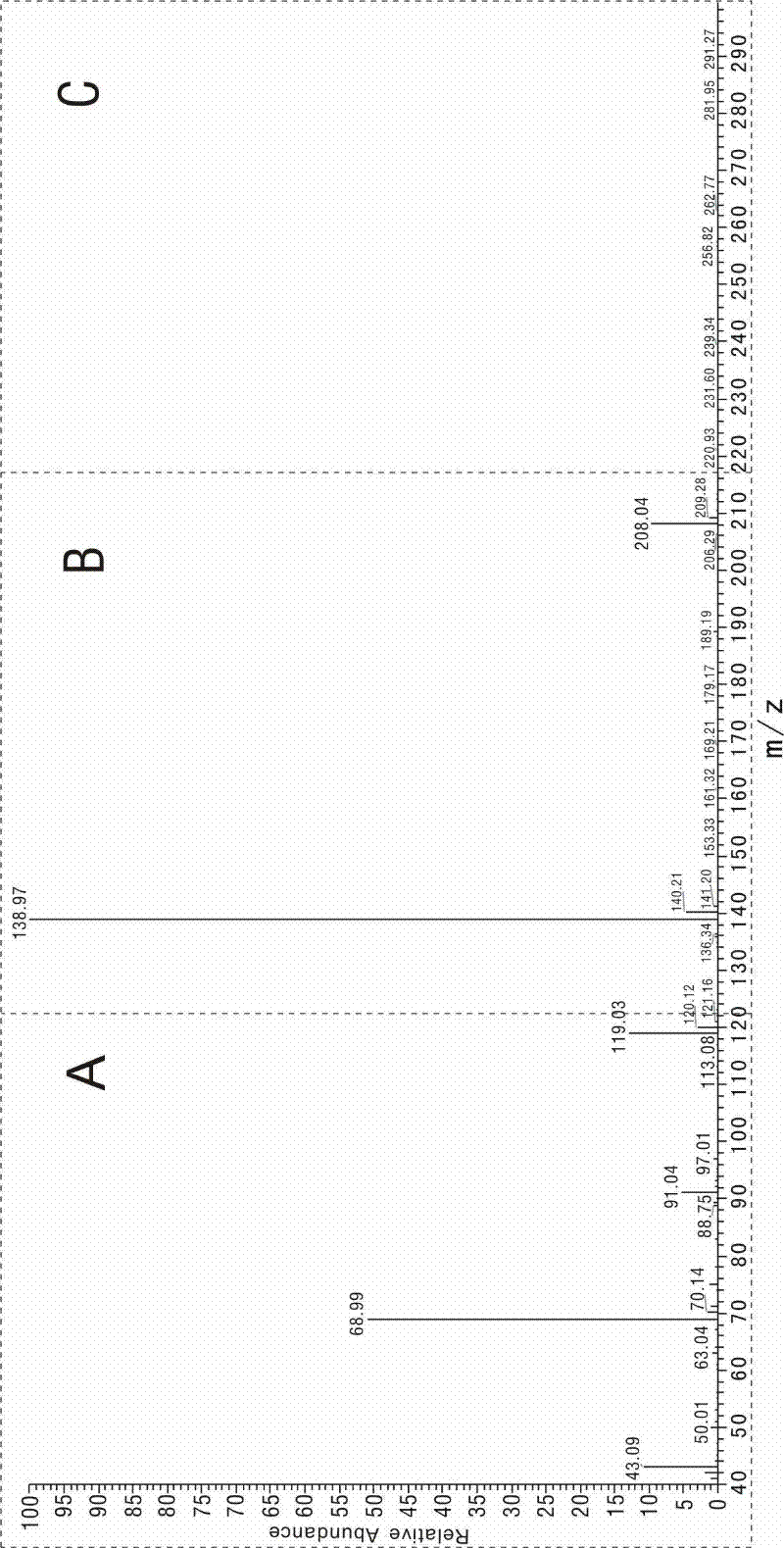

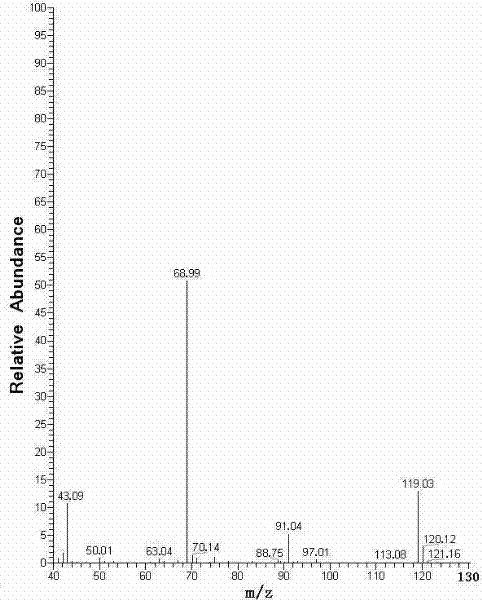

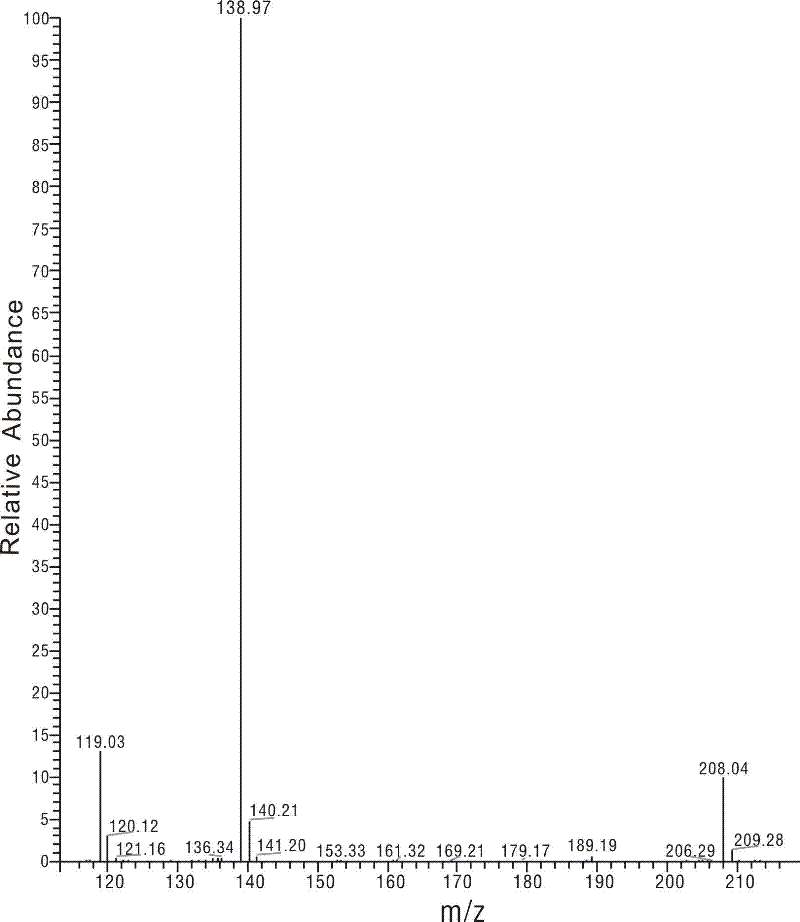

Image

Examples

Embodiment 1

[0023] In a 1000mL three-neck flask, add 696 g (3 moles) of phenyl trifluoroacetoacetate, 210 g (1 mole) of trifluoroacetic anhydride and 1.2 g (0.03 moles) of magnesium oxide, start stirring, and heat the mixture in the bottle to 50 °C React for 8 hours; then increase the temperature and heat the mixture in the bottle to 140°C, and distill the generated 1,1,1,5,5,5-hexafluoroacetylacetone while reacting to obtain 1,1,1,5, 5,5-hexafluoroacetylacetone crude product; the resulting 1,1,1,5,5,5-hexafluoroacetylacetone crude product was rectified, and the fraction with a boiling range of 69-71°C was collected to obtain a colorless liquid 140 g, namely 1,1,1,5,5,5-hexafluoroacetylacetone, yield 67.3%.

Embodiment 2

[0025] In a 1000mL three-necked flask, add 552 g (3 moles) of ethyl trifluoroacetoacetate, 210 g (1 mole) of trifluoroacetic anhydride, and 1.2 g (0.03 moles) of magnesium oxide, start stirring, and heat the mixture in the bottle to 40 ℃ for 5 hours; then increase the temperature and heat the mixture in the bottle to 140 ℃, and distill the generated 1,1,1,5,5,5-hexafluoroacetylacetone while reacting to obtain 1,1,1,5 , 5,5-hexafluoroacetylacetone crude product; the obtained 1,1,1,5,5,5-hexafluoroacetylacetone crude product was rectified, and the fraction with a boiling range of 69-71°C was collected to obtain a colorless liquid 126 g, namely 1,1,1,5,5,5-hexafluoroacetylacetone, yield 60.5%.

Embodiment 3

[0027] In a 1000mL three-neck flask, add 738 g (3 moles) of benzyl trifluoroacetoacetate, 210 g (1 mole) of trifluoroacetic anhydride and 2 g (0.05 moles) of magnesium oxide, start stirring, and heat the mixture in the bottle to 60°C React for 10 hours; then increase the temperature to heat the mixture in the bottle to 140°C, and distill the generated 1,1,1,5,5,5-hexafluoroacetylacetone while reacting to obtain 1,1,1,5, 5,5-hexafluoroacetylacetone crude product; the obtained 1,1,1,5,5,5-hexafluoroacetylacetone crude product was rectified, and the fraction with a boiling range of 69-71°C was collected to obtain a colorless liquid 142 g, namely 1,1,1,5,5,5-hexafluoroacetylacetone, yield 68.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com