Sputtering carrier

A carrier and sputtering technology, which is applied in the field of carriers, can solve the problems of difficult cleaning and high cost, and achieve the effects of no static residue, low manufacturing cost and small deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

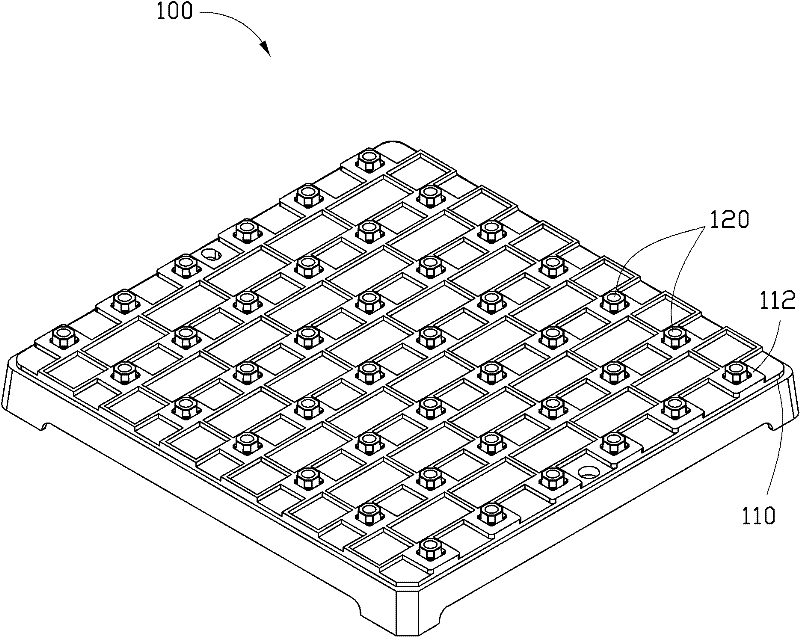

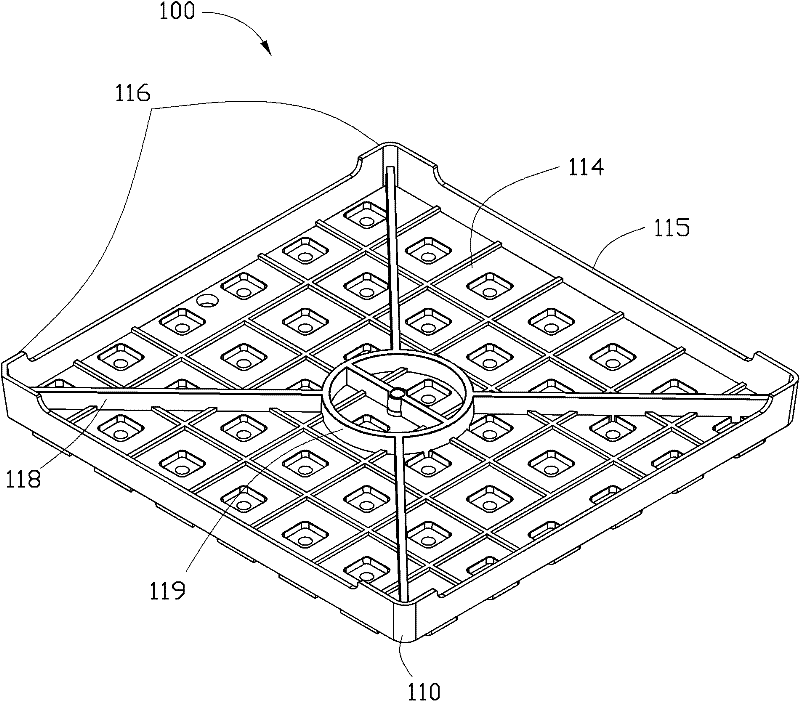

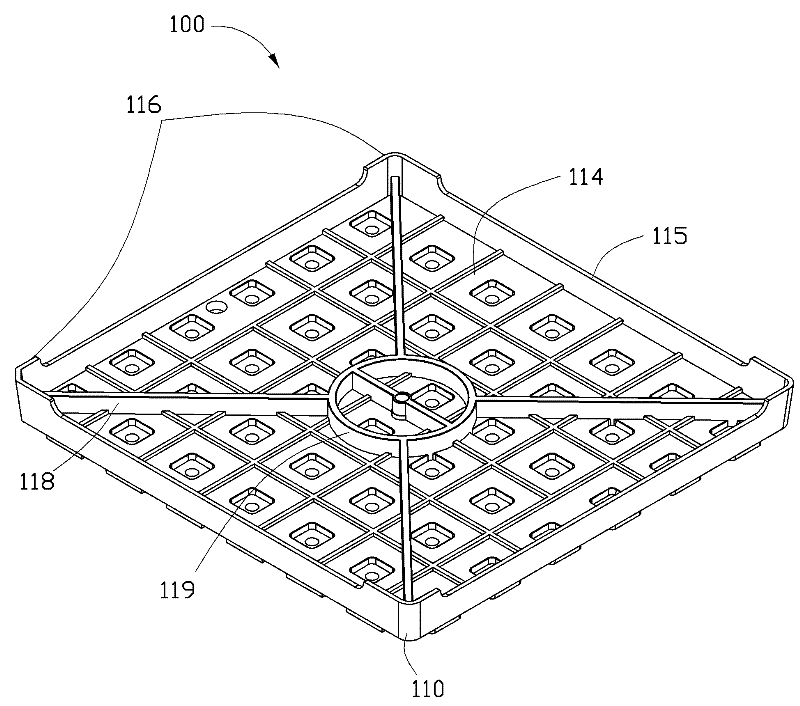

[0018] see figure 1 , a sputtering carrier 100 provided by a preferred embodiment of the present invention includes a base 110 and a plurality of support bases 120 arranged in an array on one side of the base 110 . The base 110 is rectangular and includes an upper surface 112 and a lower surface 114 opposite to the upper surface 112 . The supporting bases 120 are evenly spaced on the upper surface 112 of the base 110 . A supporting wall 115 extends around the lower surface 114 of the base 110 . Four corners of the supporting wall 115 respectively extend a leg 116 along a direction perpendicular to the lower surface. A reinforcing rib 118 extends from the inner side of each leg 116 toward the center of the base 110 . The plurality of reinforcing ribs 118 intersect on an annular wall 119 at the center of the lower surface 114 of the base 110 .

[0019] The sputtering carrier 100 is made by melt-blending polycarbonate and glass fiber and molding. Specifically, polycarbonate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com