Impurity cleaning device of air outlet mesh

A technology of air outlet net and impurity removal, which is applied in the field of cotton impurity removal, and can solve the problems affecting the smoothness of ventilation, the uniformity of wind pressure of the foreign fiber removal device, and the cleaning effect of the foreign fiber removal device, so as to ensure normal operation and effective separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

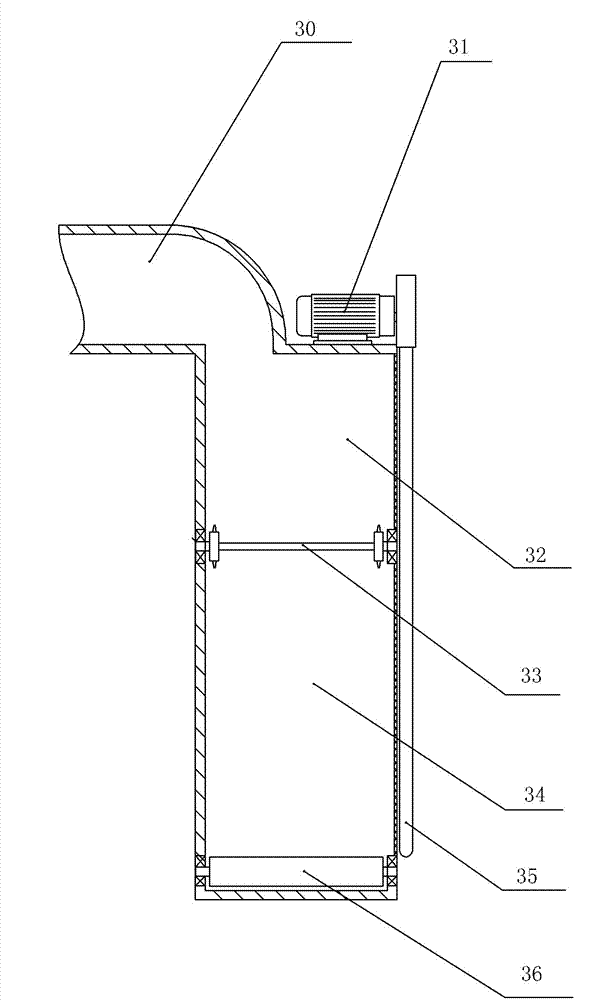

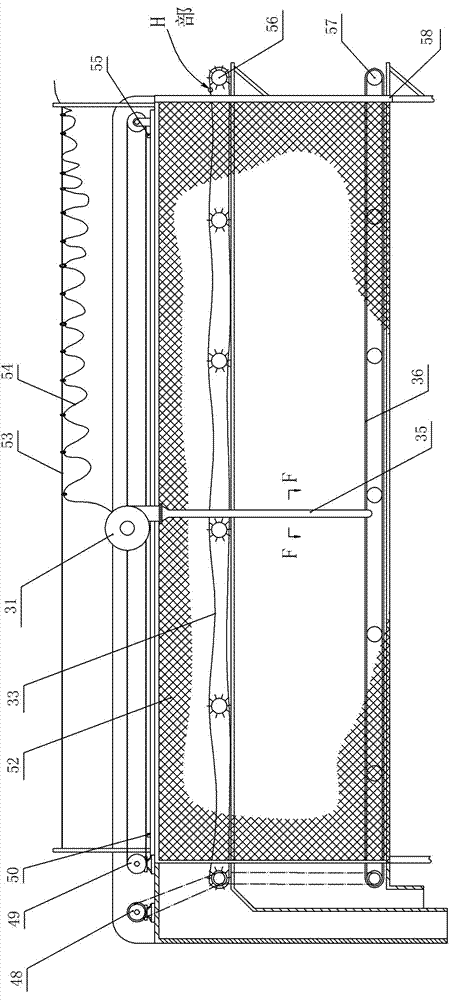

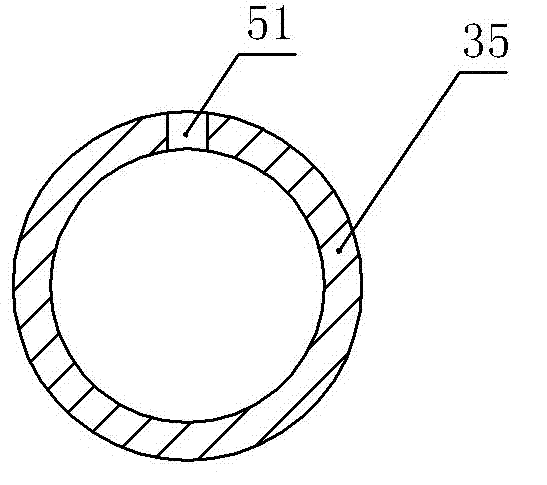

[0020] Embodiment one: see figure 1 , figure 2 , image 3 , Figure 4 , The air outlet net cleaning device is arranged on the side of the positive pressure foreign fiber removal device, and the upper part of the positive pressure foreign fiber removal device communicates with the upper part of the foreign fiber separation chamber. The air outlet net cleaning device is provided with an upper exhaust chamber and a lower exhaust chamber, and an overflow cotton conveyor belt is arranged between the two exhaust chambers, and the overflow cotton conveyor belt is a grid type conveyor belt, see Figure 4 , the rotating shafts of the parallel circular chains are respectively fixed together by connecting rods, and the synchronous operation of the circular chains on both sides drives each connecting rod to move forward, so as to achieve the purpose of filtering foreign fibers and conveying overflow cotton. The conveying end of the overflow cotton conveyor belt It is provided with a c...

Embodiment 2

[0022] Embodiment two: see Figure 5 , the content is basically the same as that of Embodiment 1, and the similarities will not be repeated. The difference is that: the two sides of the upper end of the upper foreign fiber separation chamber are provided with air outlet net cleaning devices.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com