Hydraulic mechanical heat dissipation device for railway transportation

A technology of hydraulic machinery and heat dissipation device, which is applied in the direction of fluid pressure actuating device, mechanical equipment, oil supply tank device, etc., can solve the problems of affecting heat discharge, cylinder explosion, reduction of heat dissipation effect of hydraulic oil radiator, etc., and achieves convenient collection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

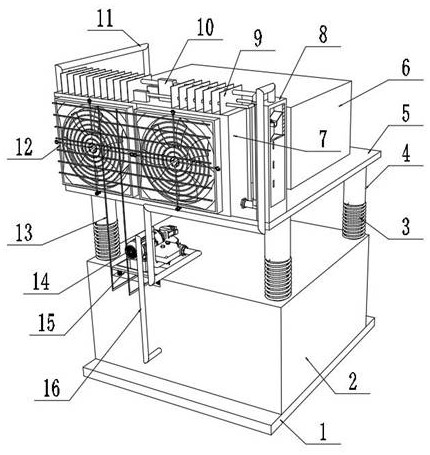

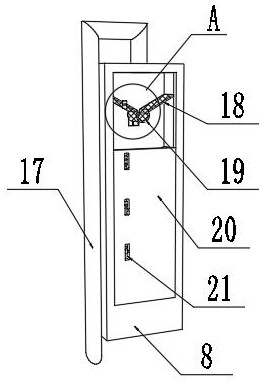

[0034] Hydraulic mechanical heat dissipation device for railway transportation, such as Figure 1-6As shown, including the first fuel tank 2 and the second tank 6 fixed to the top of the base 1, the bottom end of the second oil tank 6 is fixed to the top end of the first fuel tank 2 by a damper buffer mechanism; the damping buffer mechanism includes four groups The telescopic column 4 and the first spring 3 wrapped in the outer wall of the telescopic column 4, the bottom end of the second oil tank 6 secures the support plate 5 by the bolt, and both ends of the telescopic column 4 are fixed to the bottom corner of the support plate 5, respectively, respectively. The top angle of the tank 2, the outer side of the telescopic column 4, the first spring 3 can effectively support the second oil tank 6 above the support plate 5 while reducing the vibration wear of the device during rail transportation; the top end of the support plate 5 One side is fixed by screws, and the fan side of the...

Embodiment 2

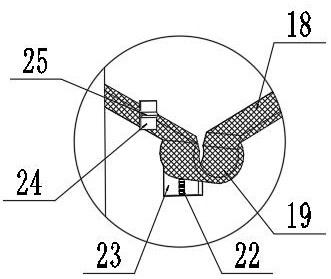

[0039] Hydraulic mechanical heat dissipation device for railway transportation, such as Figure 7 As shown, in order to further improve the problem of clearing the dust-proof mesh 12 surface product; the present embodiment, the following improvements are made based on the first embodiment: the outer wall of the cleaner 27 is provided with a bevel 30, a bevel 30, and a cleaning frame. 27 Near the outer wall of the hydraulic oil heat exchanger 7 is provided with two or more cleaning brushes 29; by providing a bevel 30, the design of the slope 30 can prevent the straight-sheet cleaning frame 27 to block dust falling, providing a sweep dust Cleaning space, avoiding the phenomenon of cleaning of the cleaning operation, and two outer walls of the bevel 30 and the cleaner 27 are provided with two or more outer cleaning brushes 29, and the vibration generated by the oil pump 14 can be used. The vibrating cleaning 29 performs scratching dust, improves the cleaning effect.

[0040] When used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com