Method of Microwave Heating Underground Oil Shale for Oil and Gas Exploitation and Simulation Experiment System

A microwave heating and simulation experiment technology, which is applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., can solve the problems of low thermal conductivity, slow heat transfer rate and slow heating rate of oil shale temperature in oil shale.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

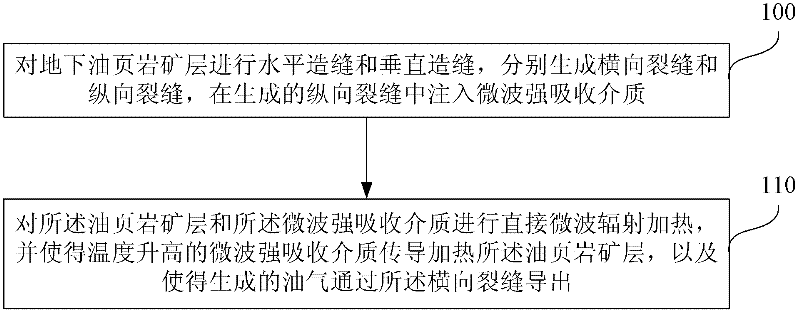

[0025] figure 1 It is an overall flow chart of a method for extracting oil and gas from oil shale with microwave and subsurface heating in Example 1 of the present invention. Such as figure 1 As shown, the method includes:

[0026] 100. Carry out horizontal and vertical fracture creation on the underground oil shale mineral layer, respectively generate transverse cracks and vertical cracks, and inject microwave strong absorption medium into the generated longitudinal cracks;

[0027] 110. Perform direct microwave radiation heating on the oil shale deposit and the microwave strong absorption medium, conduction heating of the oil shale deposit by the microwave strong absorption medium with increased temperature, and allow the generated oil and gas to pass through the transverse Crack export.

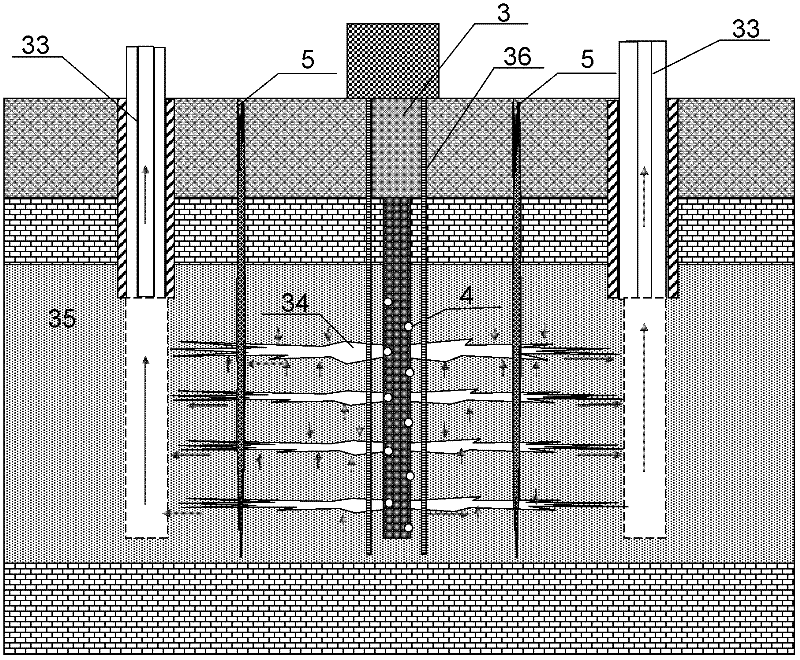

[0028] For details below, please refer to Figure 2A and Figure 2B ,in, Figure 2A It is the application schematic diagram of the microwave heating oil shale extraction method for o...

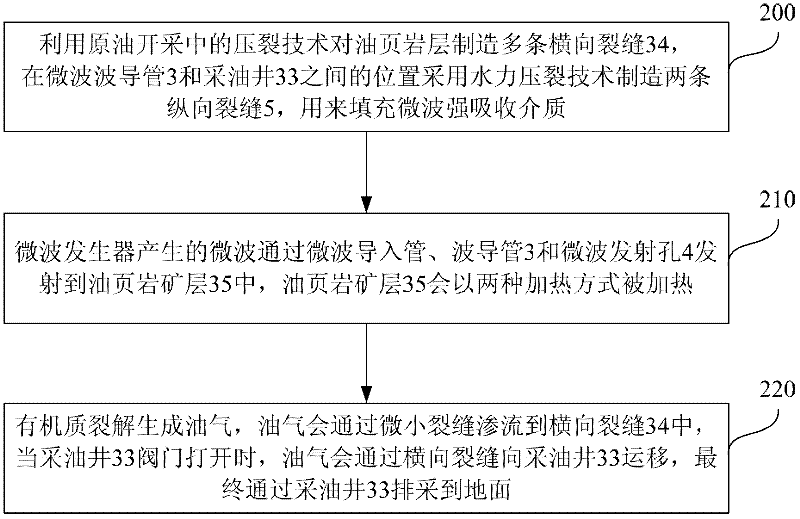

Embodiment 2

[0034]Embodiment 2 of the present invention provides a simulation experiment system for exploiting oil and gas from underground oil shale by microwave heating. This simulation experiment system mainly heats oil shale and microwave strong absorption medium through microwaves. After the temperature of microwave strong absorption medium rises, the oil shale is heated by heat conduction. Therefore, the reaction system is a combination of heat radiation and heat conduction. Heating oil shale, the simulation experiment system can be used to carry out the heat conduction law and shale oil recovery rate of oil shale microwave mining in different areas under different microwave powers, and provide information for microwave heating in situ oil shale extraction in different areas. parameters and development ideas.

[0035] Such as image 3 As shown, a kind of simulation experiment system applied to the mining method of embodiment 1 of embodiment 2 of the present invention comprises:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com