Straw solid fuel hot blast stove

A solid fuel, hot blast stove technology, applied in the directions of fluid heaters, air heaters, drying gas layout, etc., can solve the problems of large volume, low degree of industrialization, scattered straw distribution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

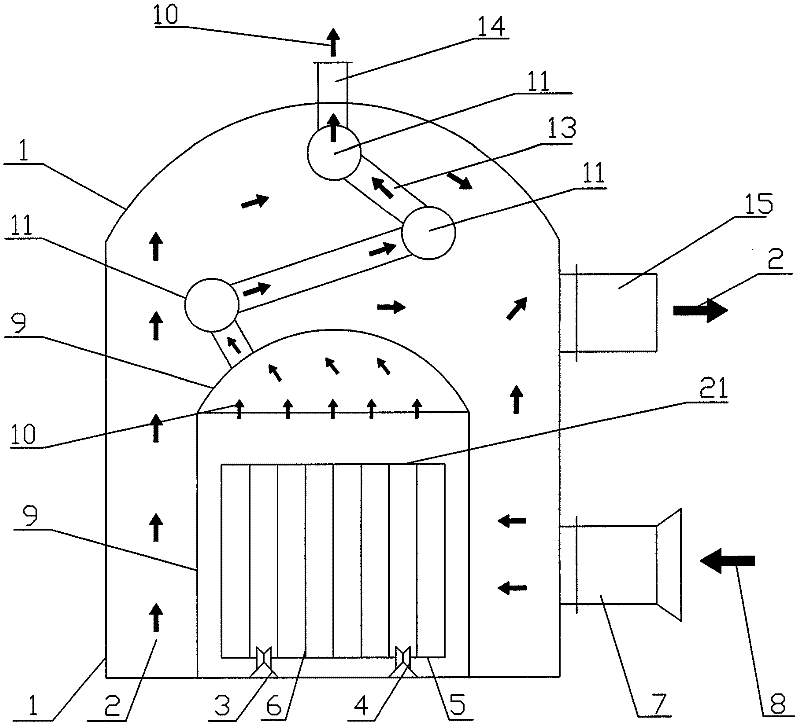

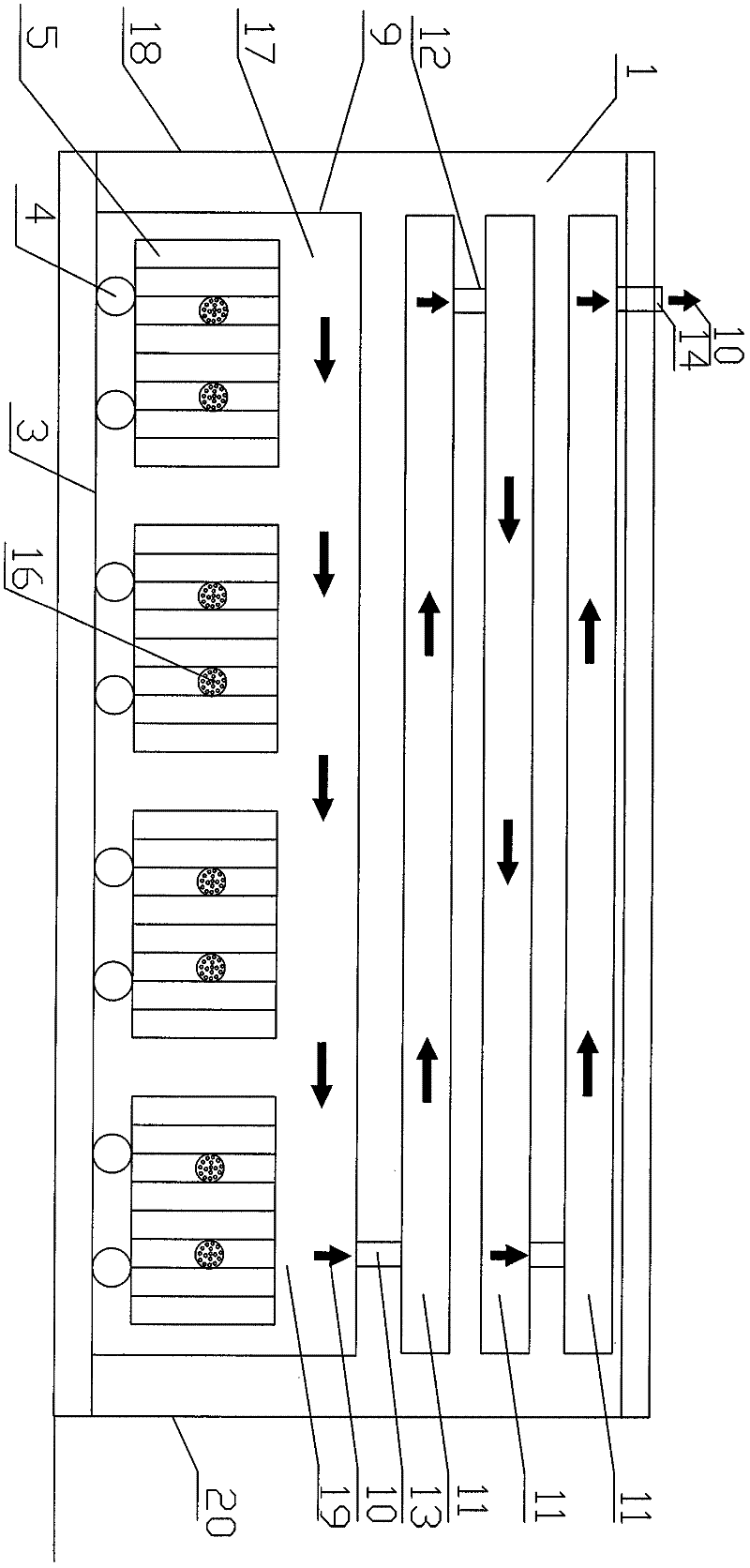

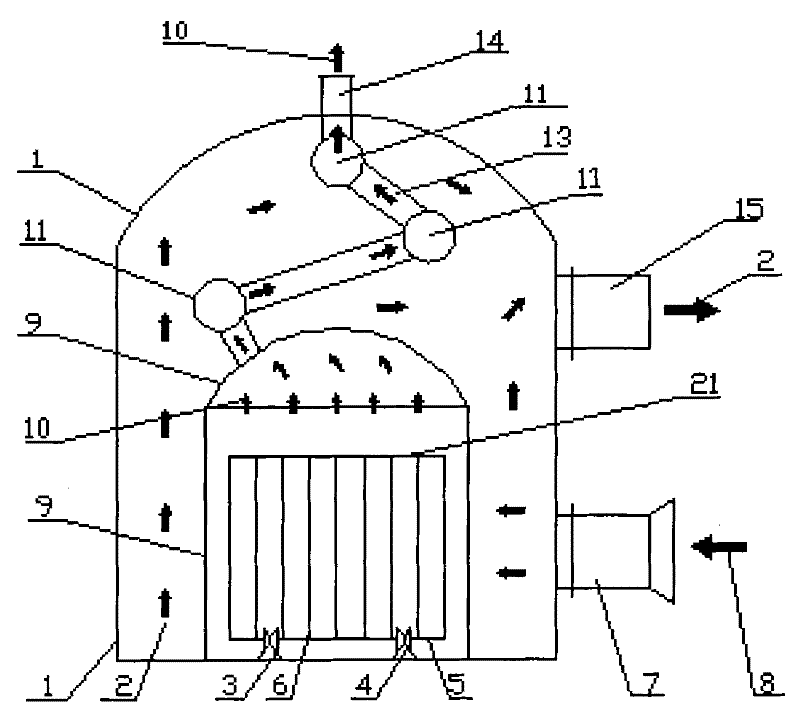

Embodiment Construction

[0016] The steel bar basket is formed by welding the vertical round steel bar 6 and the horizontal round steel bar 21. There is a certain distance between each steel bar. The five sides of the steel bar basket are welded and closed to form a basket. V-shaped walking wheels 4 are installed under the basket, and briquette-shaped straw solid fuel 16 together form a straw solid fuel combustion basket 5, which is arranged in a row on the track 3 in the horizontal steel plate refractory hearth 9, and along the track 3 walking; the heat exchanger of the hot blast stove is composed of a horizontal steel plate refractory earth furnace 9, smoke exhaust heat exchange pipes 11 arranged in zigzag, left connecting smoke pipe 12, and right connecting smoke pipe 13; the briquette-shaped straw solid fuel 16 Fill the straw solid fuel combustion basket 5 and push it into the horizontal steel plate refractory soil furnace 9 from the feed door 18. The horizontal steel plate refractory soil furnace ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com