A Gradient Heating Device and Method for Improving the Uniformity of 0.1mm Cover Layer of Blu-ray Disc

A gradient heating, Blu-ray disc technology, applied in the direction of optical record carrier, optical record carrier manufacturing, etc., can solve the problems of glue coating thickness variation, uneven cover layer thickness, pull back, etc., to improve uniformity and solve cover layer Inhomogeneity, the effect of eliminating the influence of peak covering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

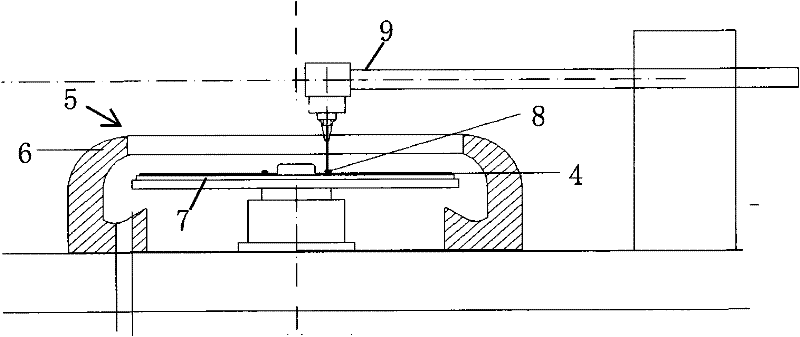

[0020] According to the present invention, in the process of forming the 0.1mm cover layer of a BD Blu-ray disc, such as figure 1 As shown, the Blu-ray disc substrate 4 is first placed on the tray 7 in the spin coating bowl 6 of the spin coating machine 5 . In the first stage, at first glue is coated on the inner circle 8 of this disc substrate 4, and glue down can be carried out by a manipulator 9, and this manipulator 9 removes after coating glue; Then in the second stage, spin coating The machine starts to rotate so that the disc substrate 4 rotates together, and the glue is evenly rotated and coated on the disc substrate. With the rotation of the disc substrate, the glue spreads from the inner ring to the outer ring under the action of centrifugal force, and gradually covers the entire surface. CD substrate. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com