Automatic winding device for battery cell

A kind of equipment and automatic technology, applied in the direction of circuits, electrical components, secondary batteries, etc., can solve the problems that it is difficult to meet the development requirements of process speed and precision, cannot be directly wound with a mandrel, and increases the labor intensity of workers, so as to achieve reliable clamping The effect of holding, feeding material smoothly and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

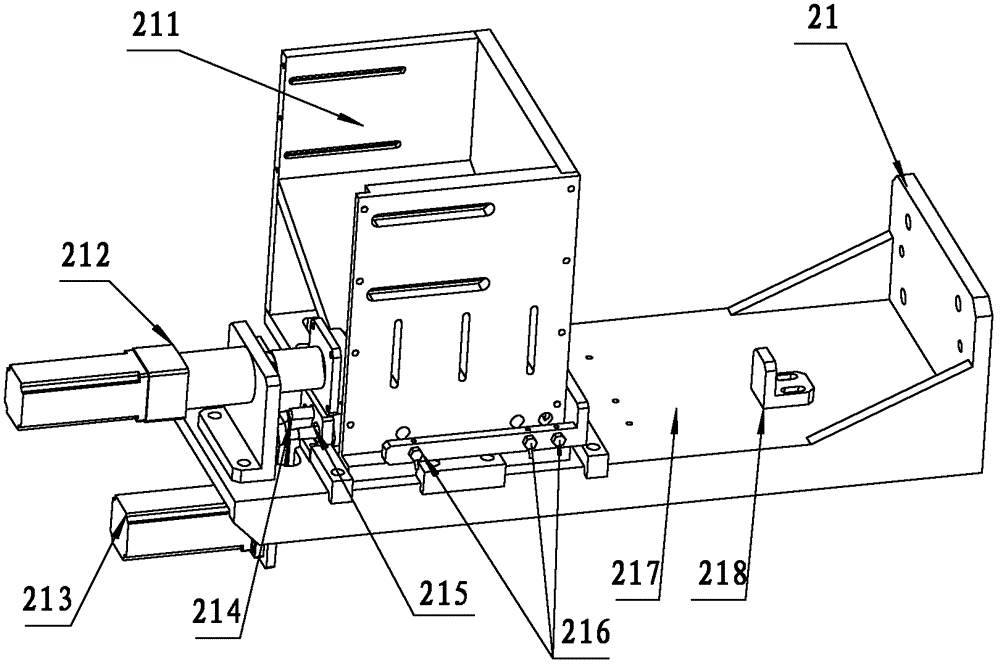

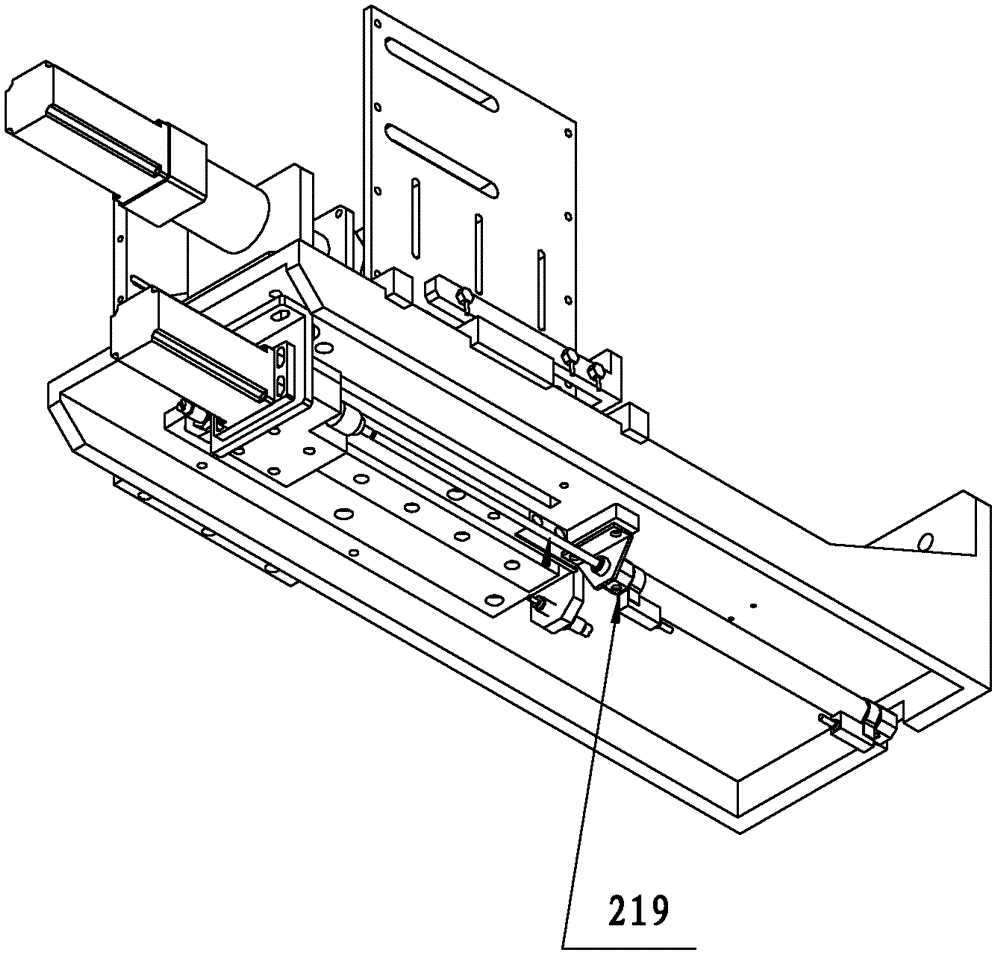

[0025] The present invention adds an automatic core changing component to realize fully automatic material distribution and feeding in the battery automatic winding equipment, which can automatically replace the next mandrel for winding after one battery core is processed and unloaded, so it is significantly The process efficiency and automation level of cell winding are improved.

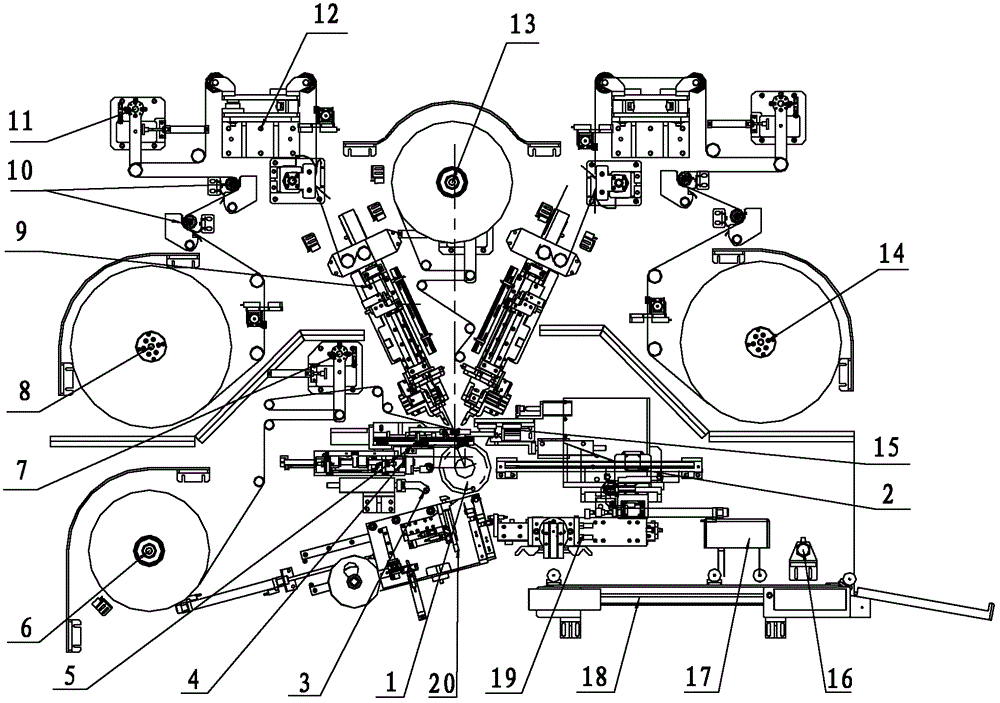

[0026] Such as figure 1 As shown, an automatic battery winding device of an embodiment includes a frame (not shown in the figure) and a winding assembly 1 installed on the frame. The end of the winding head is also provided with a clamping head for clamping the mandrel so as to drive it to wind. In one embodiment, in order to facilitate the orientation of the mandrel, when an orientation part is provided on the mandrel, the shape of the clamping head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com