A coaxial laser coupling package device fixture

A coaxial laser and packaging device technology, which is applied to laser components and other directions, can solve the problems of coaxial laser coupling packaging device fixtures and not many device fixtures, etc., so as to improve work efficiency and product quality, and facilitate device loading and unloading and operation Convenience and concise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, and the structure, assembly and working principle of the present invention will be introduced in detail.

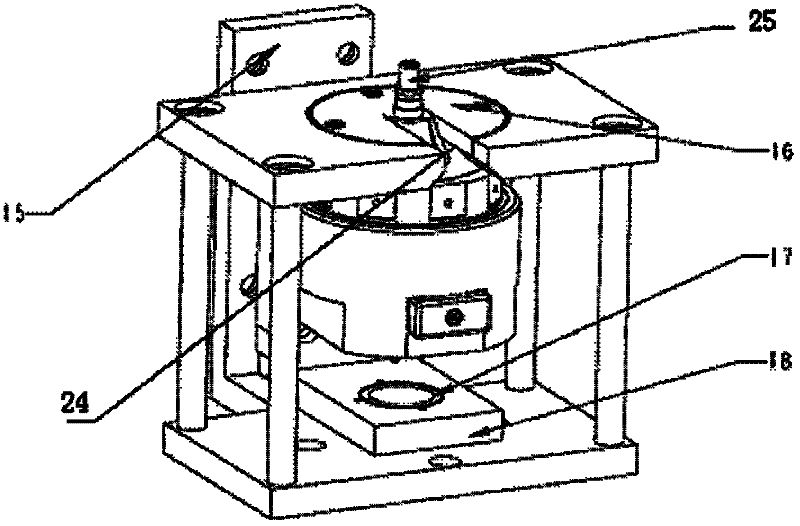

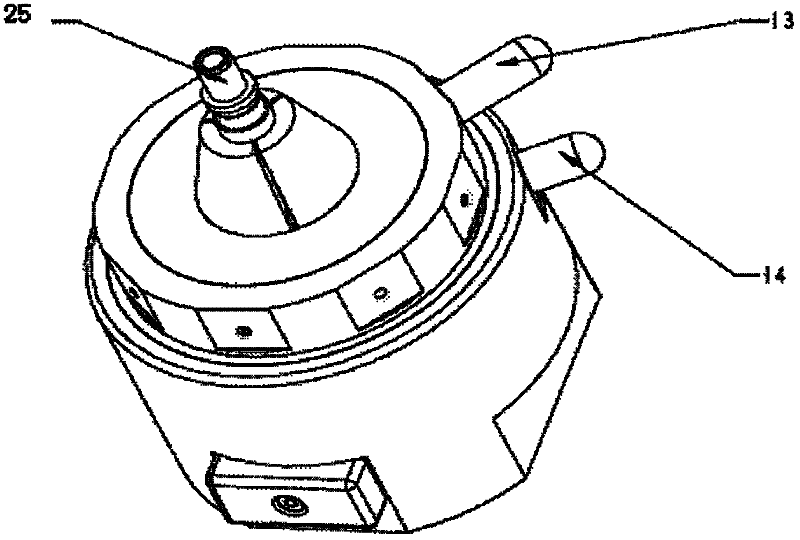

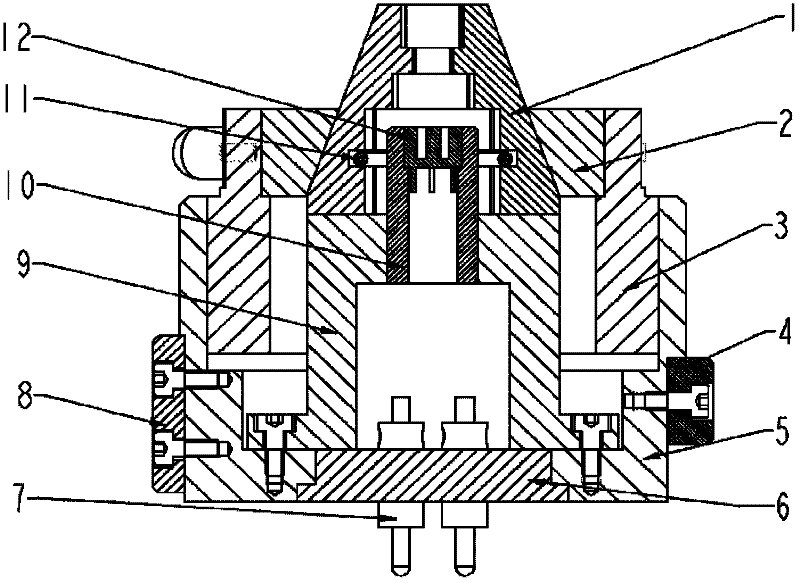

[0022] Such as figure 1 , Figure 5 As shown, it is a schematic diagram and a side view of a three-dimensional structure of the present invention, a clamp lifting seat 18 is installed on the clamp mounting seat 15, a bottom wiring groove 17 is provided on the clamp lifting seat 18, and a The cone stopper 16, whose cone angle is 20°, is used to locate the positions of the three clamp petals 1 in the clamp body on an inclined plane, which can play a good role in positioning and centering. The TOSA / ROSA product 25 is inserted into the LD special socket 12 , when the three clamp petals 1 of the clamp body clamp the package component of TOSA / ROSA product 25, the cone stopper 16 can keep the axis of the package component vertical. The conical su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com