Power plant with co2 capture

A power equipment, CO2 technology, applied in the direction of mechanical equipment, engine components, engine control, etc., can solve the problems of performance, efficiency and operability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

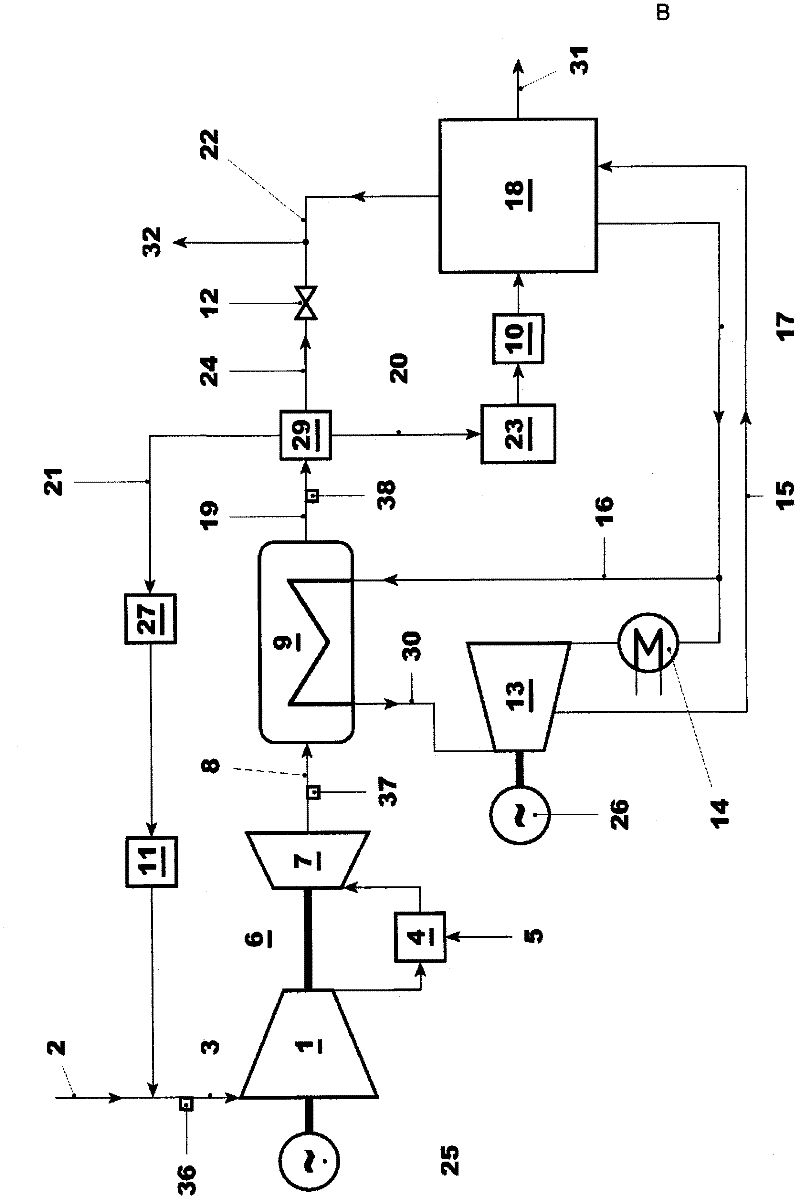

[0058] The power plants used to perform the proposed method include conventional CCPPs, equipment for flue gas recirculation and CO 2 capture system 18 .

[0059] exist figure 1 A typical arrangement with post combustion capture and flue gas recirculation is shown in . A turbine 6 driving a first generator 25 is supplied with compressor inlet gas 3 and fuel 5 . The compressor inlet gas 3 is a mixture of ambient air 2 and flue gas recirculated through the flue gas recirculation line. Inlet gas is compressed in compressor 1 . The compressed gas is used in combustor 4 to burn fuel 5 and the pressurized hot gas is expanded in turbine 7 . Its main outputs are electrical power and hot flue gas8.

[0060] The hot flue gas 8 of the gas turbine passes through the HRSG 9 , which generates live steam 30 for the steam turbine 13 . The steam turbine 13 is arranged either in a single-shaft configuration with the gas turbine 6 and the first generator 25 , or in a multi-shaft configurat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com