Device and method for machining inner hole of bent pipe of nuclear power main pipeline

A technology for processing devices and main pipelines, applied in metal processing equipment, manufacturing tools, boring/drilling, etc., can solve problems such as low work efficiency, heavy workload, and inability to realize mass production, so as to improve processing quality and ensure cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

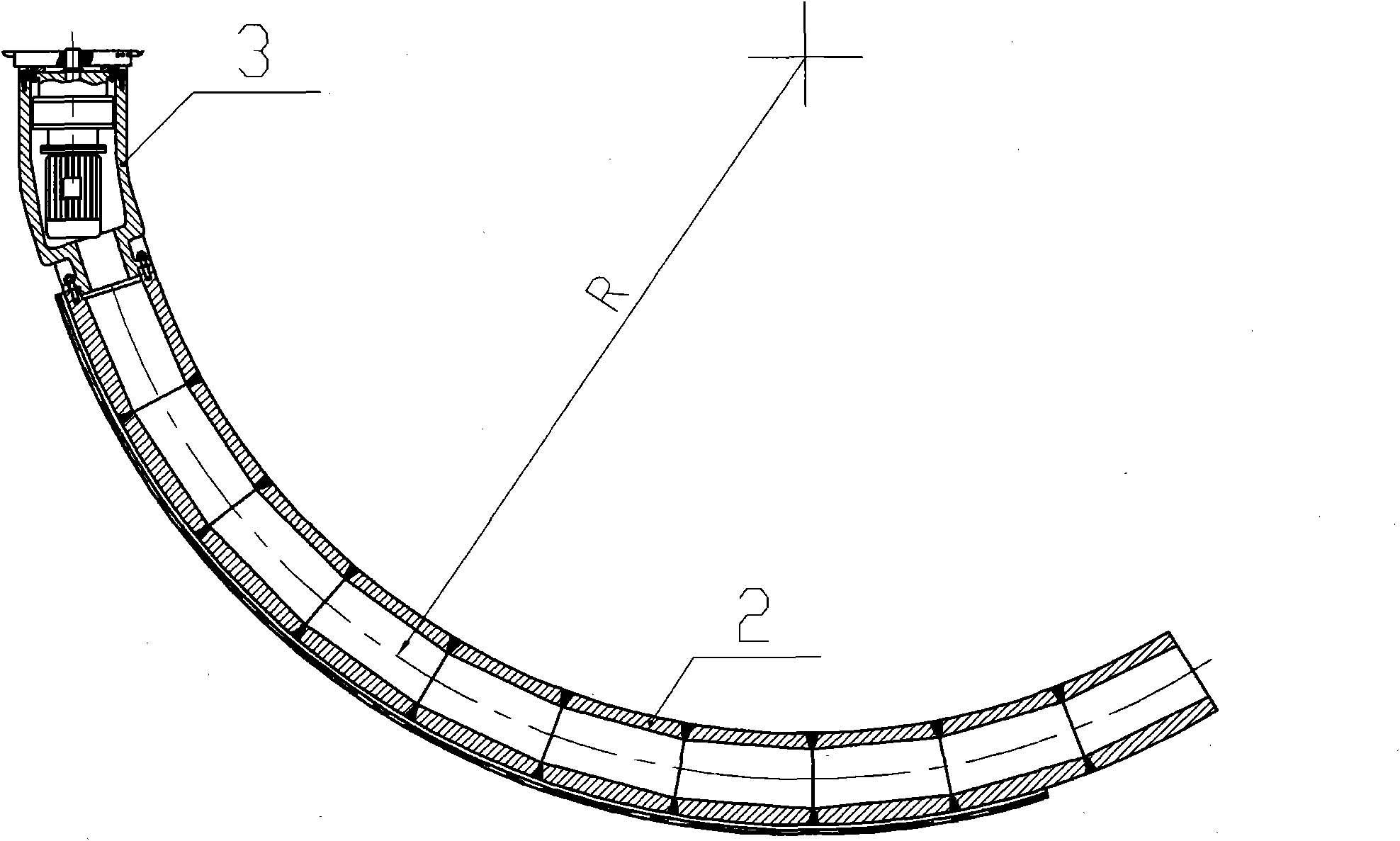

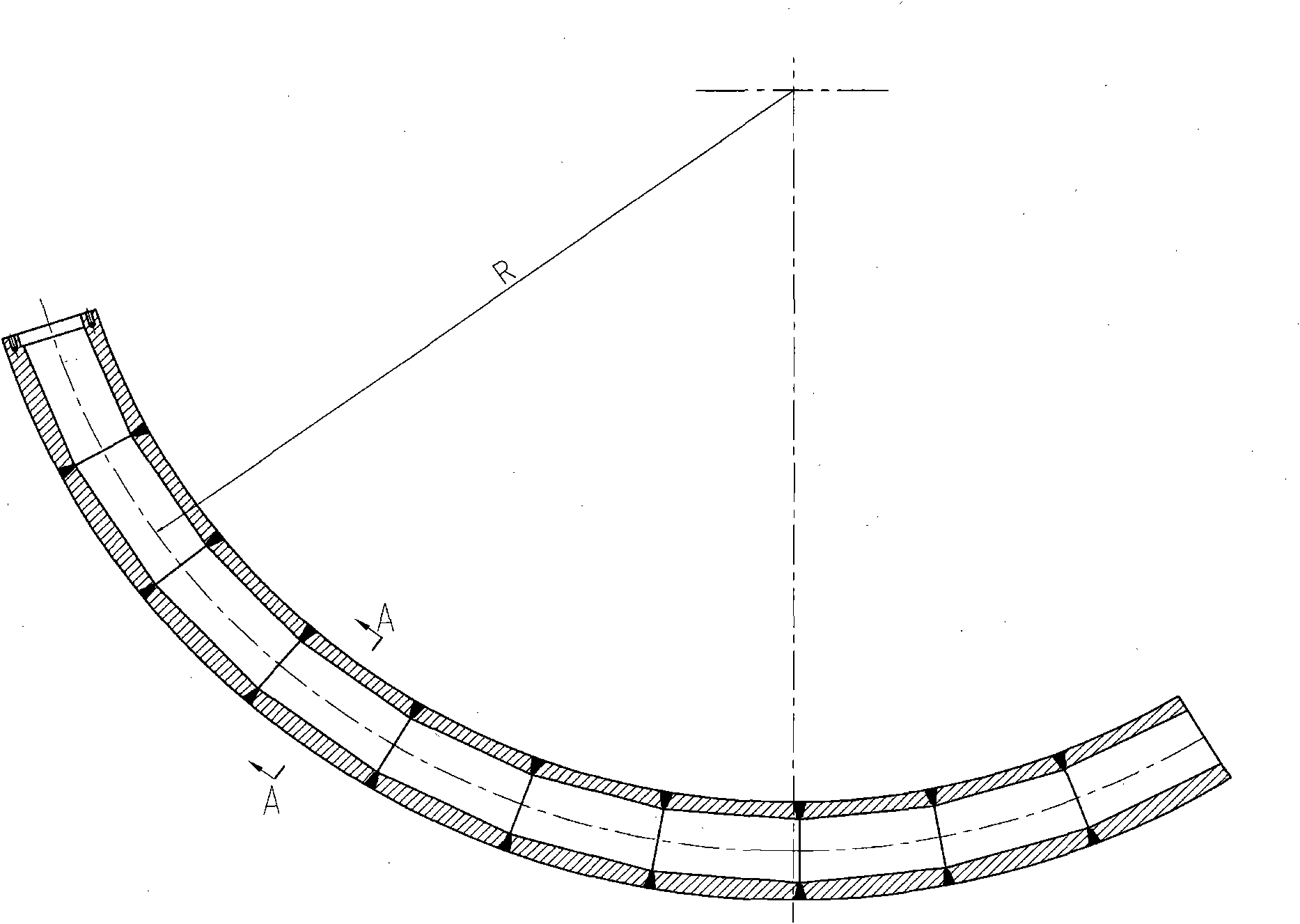

[0034] Such as figure 2 As shown, the processing device for the inner hole of the main pipeline elbow of nuclear power of the present invention includes an arc boring bar 2, a tool rotation power source 3, a large ring gear bar 4, and a pinion 5, and the tool rotation power source 3 is arranged on the arc boring The flange interface at one end of the rod 2 is connected, and the tool rotation power source 3 is the main cutting power source; the outer side of the arc-shaped boring bar 2 is fixed with a large gear ring 4, and the pinion 5 meshes with the large gear ring 4 to drive the boring bar. feed.

[0035] Such as image 3 , Figure 4 As shown, the cross-section of the arc-shaped boring bar 2 is octagonal, and one end is a flange interface for connecting with the rotary power source 3 of the tool.

[0036] The arc-shaped boring bar 2 is assembled by multi-section welding, and then integrally processed and formed.

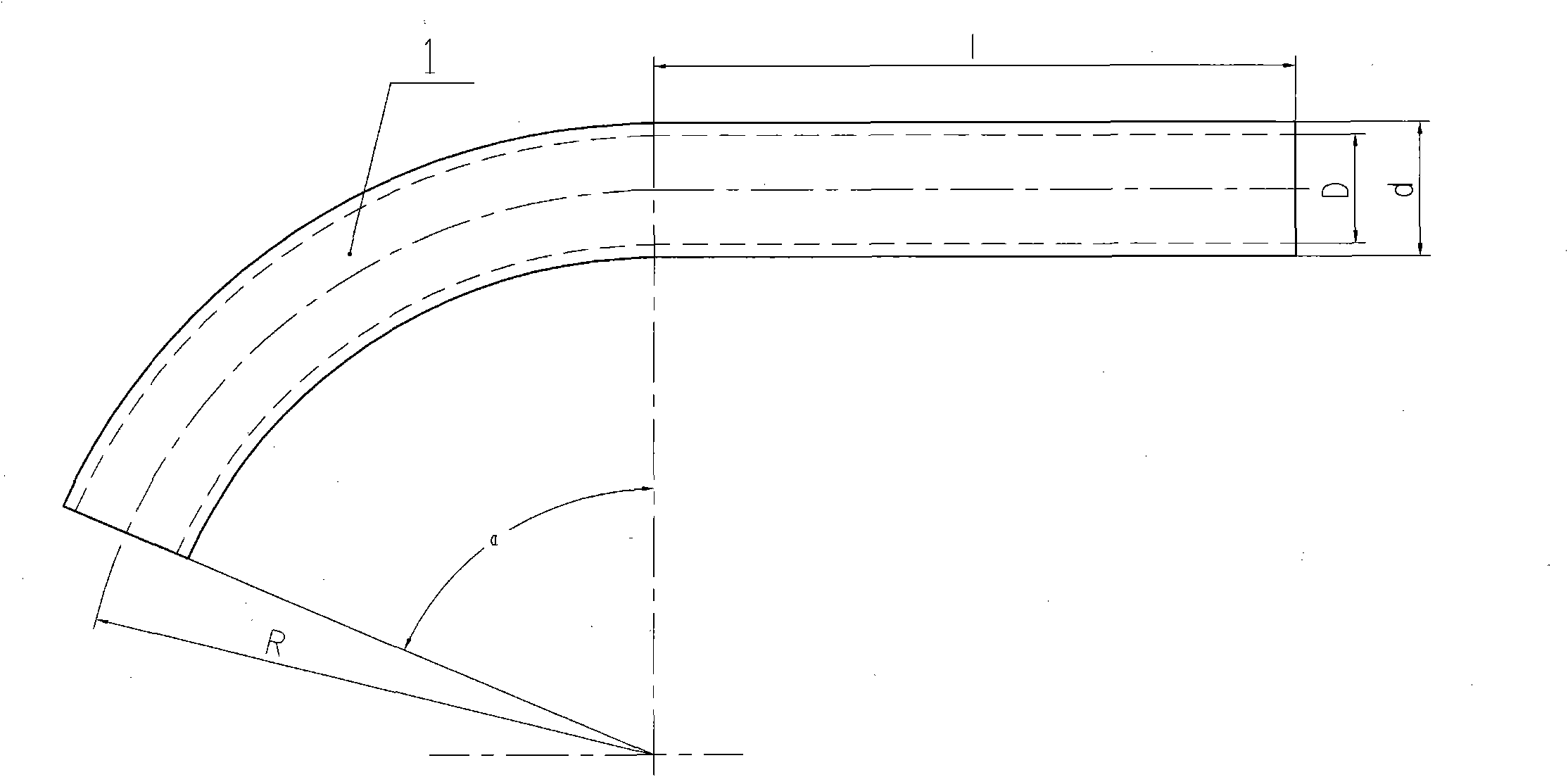

[0037] The radius of the central axis of the arc-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com