Non-blocking biomass pellet fuel molding machine

A biomass pellet and molding machine technology, applied in material molding presses, presses, manufacturing tools, etc., can solve problems such as affecting the working efficiency of the machine, downtime for maintenance, damage to bearing components, etc., to improve continuous working time and The effect of production efficiency, reducing failure rate and reducing working temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

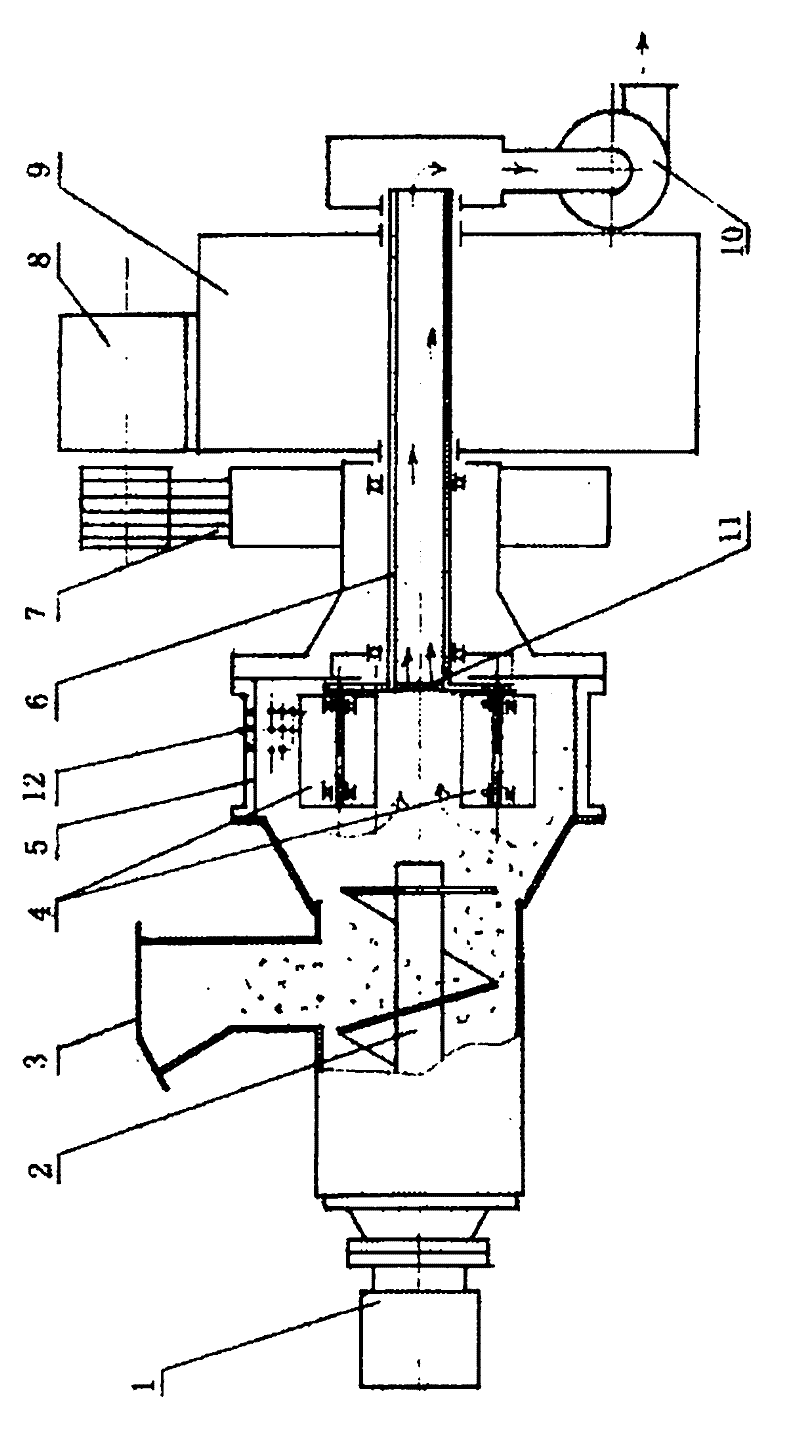

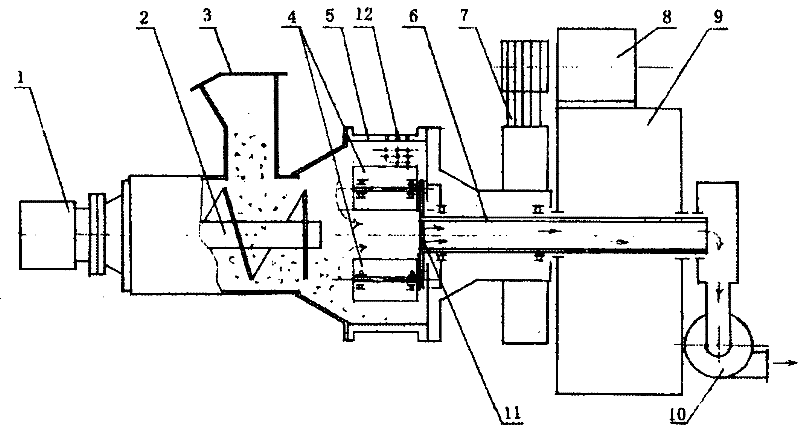

[0008] like figure 1 As shown, the blockage-free biomass pellet fuel molding machine consists of a frame 9, a support shaft 6 mounted on the frame 9, a ring die 5 mounted on the support shaft 6, and a center pressure wheel located in the ring die 5 4. It is composed of the feed chute 3 located at the feed inlet of the ring die, the feed screw 2 connected to the feed motor 1 located in the feed chute 3, the pulley mechanism 7 that drives the ring die 5 to rotate, and the main motor 8. Its characteristics The supporting shaft 6 is a hollow shaft, the end of the hollow shaft stretching in the ring die is provided with an orifice 11 , and the other end of the hollow shaft is connected with an induced draft fan 10 . During operation, the high-temperature steam in the ring die 5 enters the hollow shaft 6 through the orifice plate 11 on the end face of the hollow shaft 6 under the action of the induced draft fan 10, and then is drawn out of the machine body by the induced draft fan 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com