Solar cell adhesive film cutting and stacking system

A solar cell and film technology, which is applied in the direction of winding strips, sending objects, processing thin materials, etc., can solve the problems of difficulty in adjusting tension, low work efficiency, and high production costs, and achieve product quality assurance, simple and compact structure, The effect of high working stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

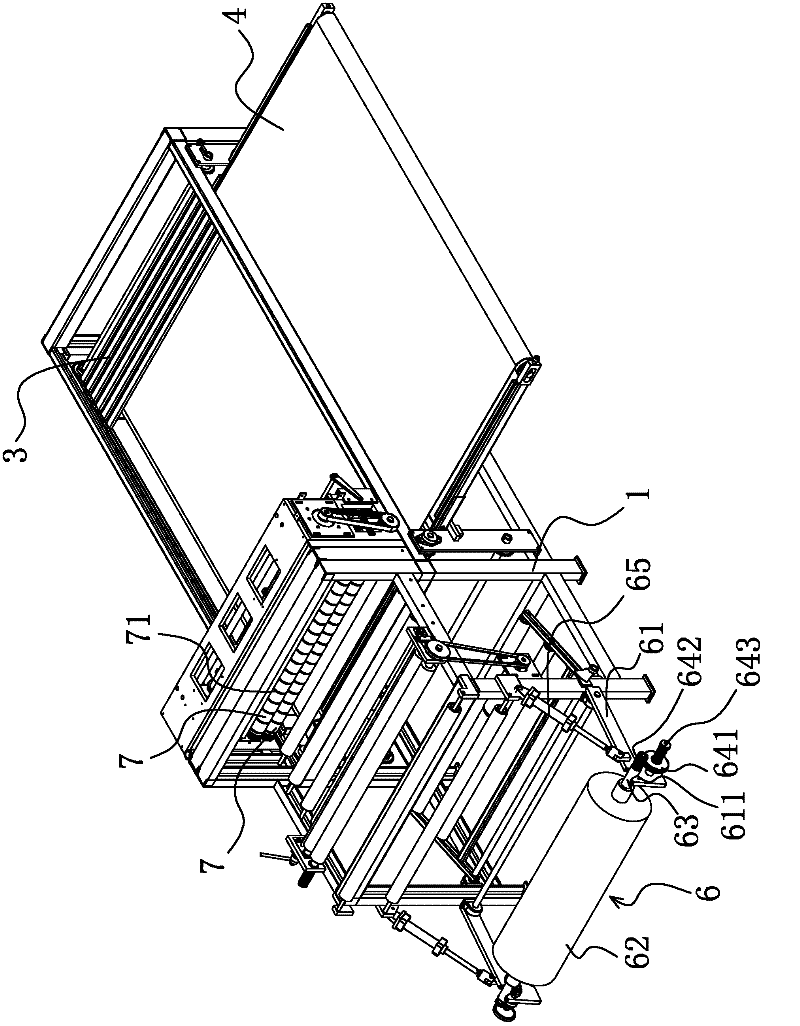

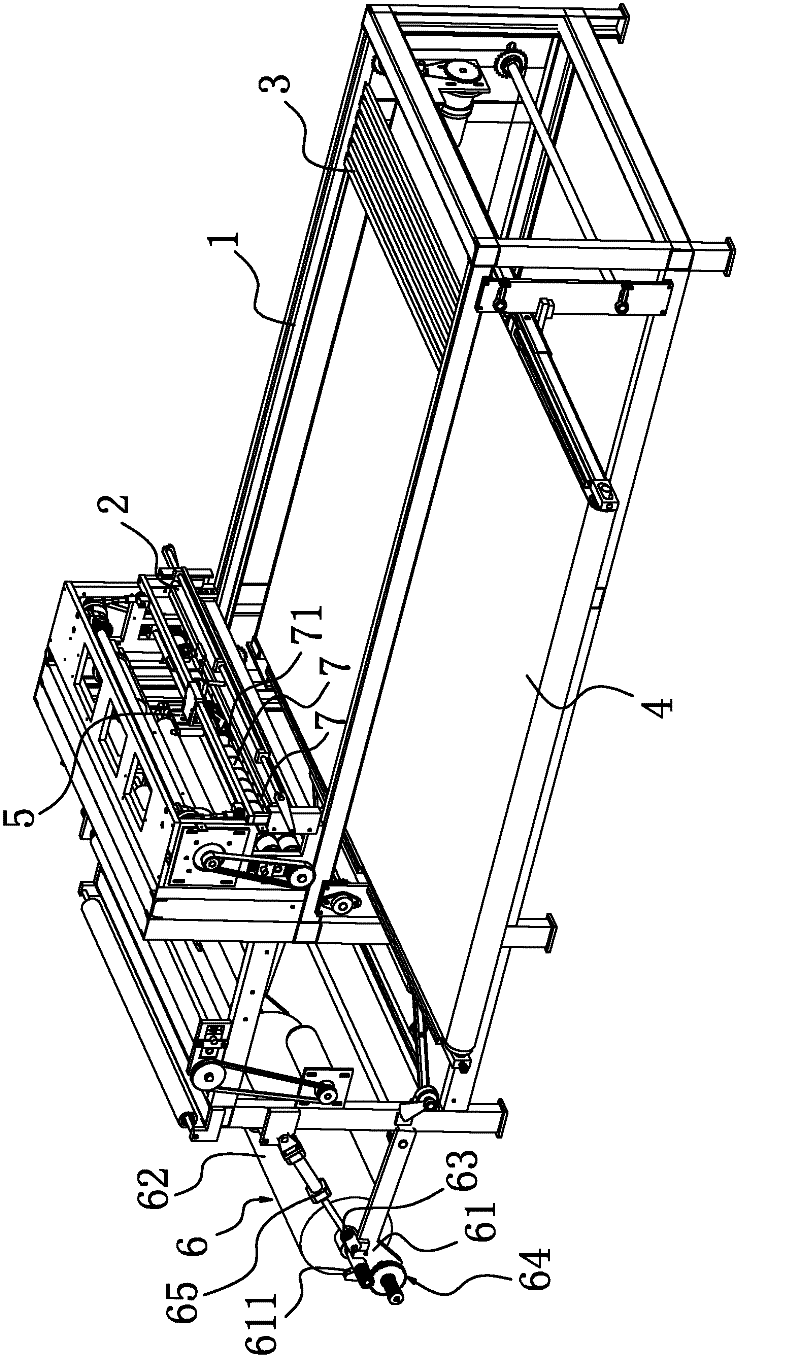

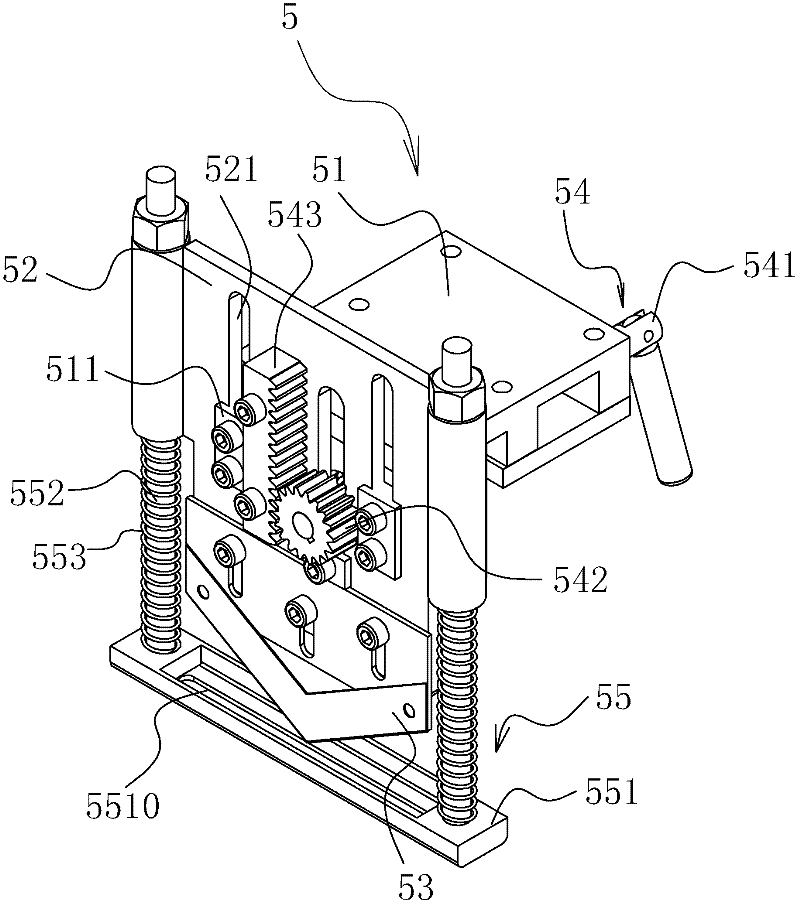

[0021] like Figure 1-5 As shown, the solar cell adhesive film cutting and stacking system includes a frame 1, a cutting mechanism 2 arranged on the frame 1 for cutting the solar cell adhesive film horizontally, and a vertical feeding mechanism 3 is provided below the cutting mechanism 2, Below the longitudinal feeding mechanism 3, a transverse feeding mechanism 4 is arranged. The system also includes a transverse cutting mechanism 5 capable of processing transverse cuts on the solar battery adhesive film while the solar battery adhesive film is cut transversely. The transverse cutting mechanism 5 is arranged above the longitudinal feeding mechanism 3 and on one side of the cutting mechanism 2, and the cutting mechanism 2 and the transverse cutting mechanism 5 are connected with the same driving device. The cutting mechanism 2 includes a static cutter 21 and a dynamic cutter 22 positioned above the static cutter 21, a gap is formed between the movable cutter 22 and the static...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com