Start-up method of direct coal liquefaction unit

A technology for direct coal liquefaction and stabilization equipment, which is applied in the preparation of liquid hydrocarbon mixtures and the petroleum industry, etc., and can solve problems that affect the operating flexibility of direct coal liquefaction equipment, affect production costs, and are difficult to handle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

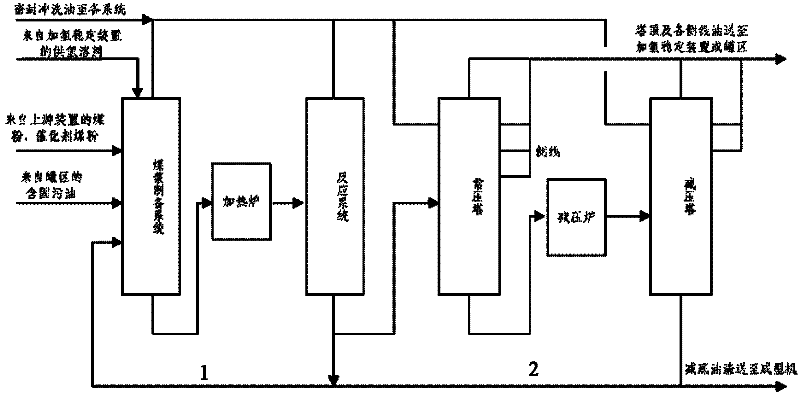

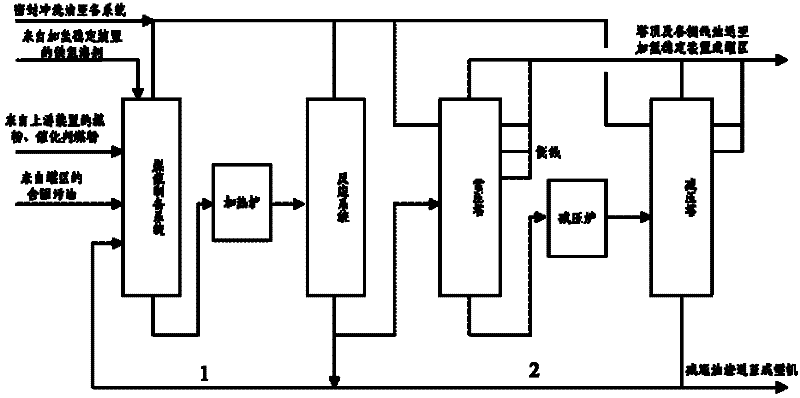

[0028] Refer below figure 1 Preferred embodiments of the present invention will be described.

[0029] Start-up method of the present invention is realized like this:

[0030] First, establish the seal oil of the reactor circulating pump; start the compressor to drive the circulating nitrogen gas to airtight the reaction system and raise the temperature, and the circulating gas circulates in the system until the temperature of the wall and pipeline of the high-pressure equipment reaches above 100 °C. Use high-pressure nitrogen to boost the pressure of the system, conduct an airtight inspection, control the boosting rate not to exceed 2MPa / h, and finally boost the pressure to a full pressure of 18.5MPa. After the nitrogen full-pressure airtightness of the system is qualified, the nitrogen gas is replaced and hydrogen gas is introduced into the device to make the system airtight with hydrogen gas.

[0031] After the hydrogen full-pressure airtightness of the reaction system is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com