Gas flow meter and throttling device used therein, ventilator, anesthesia machine

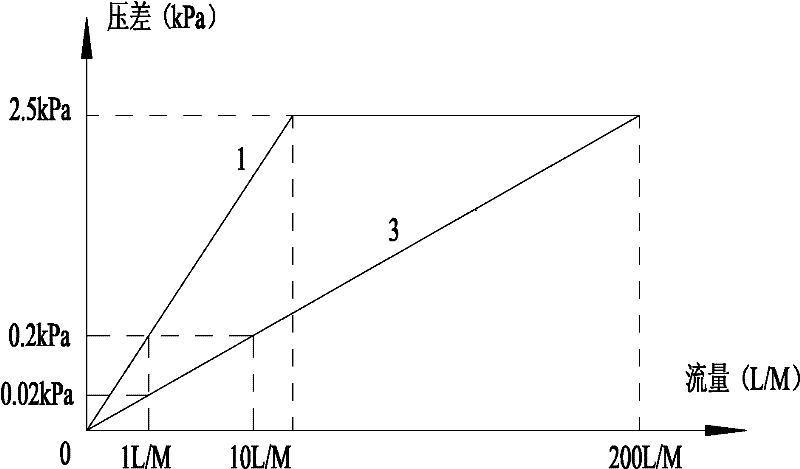

A gas flow meter and throttling device technology, applied in the field of sensors, can solve the problems of large exhalation resistance, small flow measurement range, small pressure difference change, etc., to meet the requirements of measurement accuracy, large flow detection range, and increased resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

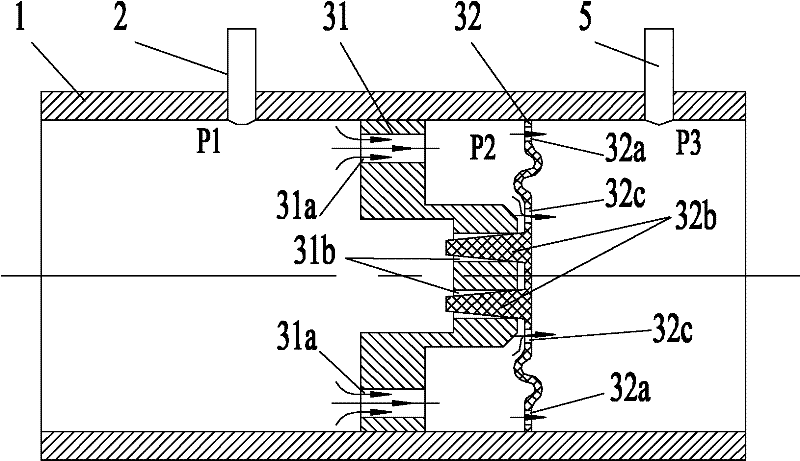

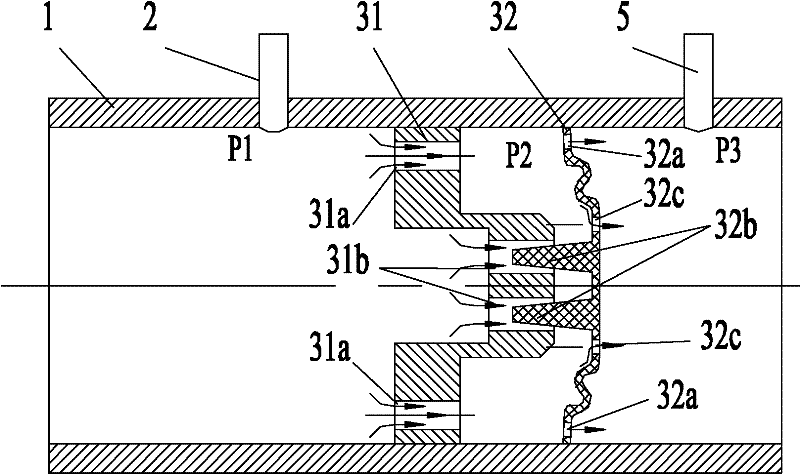

[0026] Such as figure 2 and image 3 As shown, the throttling device 3 used in the gas flow meter according to the first embodiment of the present invention is arranged in the pipeline through which the gas flows. The arrows in the figure indicate the flow direction of the gas in the pipeline. As can be seen from the figure, the throttling device 3 is provided with a throttling hole, and the cross-sectional area of the throttling hole is smaller than the cross-sectional area of the pipeline through which the gas flows. The cross-sectional area of the orifice is designed to increase as the gas flow rate reaching the throttling device 3 increases. image 3 The gas flow in the pipeline is greater than figure 2 The gas flow in the pipeline i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com