Process for making polycyclohexane dimethylene terephthalate copolymer from polyethylene terephthalate, compositions and articles thereof

A technology of cyclohexane dimethylene terephthalate and polyethylene terephthalate, applied in the field of manufacturing polyethylene terephthalate, can solve the shortage of Availability etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

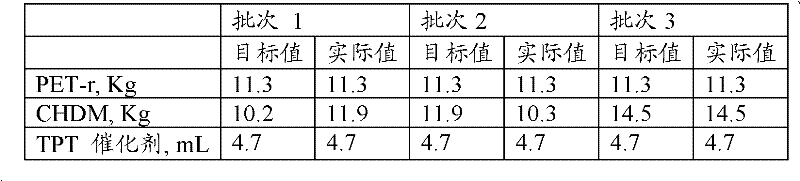

[0068] Table 1 lists the components used in the examples.

[0069] Table 1

[0070] abbreviation

illustrate

supplier

PET-r

Recycled poly(1,4-ethylene terephthalate) pellets

Futura Polyesters

TPT

Titanium tetraisopropoxide

DuPont

CHDM

Eastman

[0071] Synthesis of modified PCT from recycled PET, pilot plant method (Pilot Plant).

[0072] On a larger scale, modified polycyclohexane dimethylene terephthalate copolymers are derivatized from polyethylene terephthalate components in a helicone reactor. The helical reactor has a capacity of 40 liters and is fitted with specially designed pairs of oppositely arranged helical blades with a twist of 270 degrees; constructed of 316SS (stainless steel) with a 16g polished finish. The blade speed can be from 1 to 65 rpm. The stirrer was connected to a 7.5HP Constant Torque Inverter Duty Motor operating at 230 / 460VAC, 3PH and 60Hz. These sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com