Photovoltaic power plant with a compensated voltage source controlling the dc potential at the output of the converter

一种光伏发电站、补偿电压源的技术,应用在光伏发电站领域,能够解决耗费劳力、不希望电压接地回路电流等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

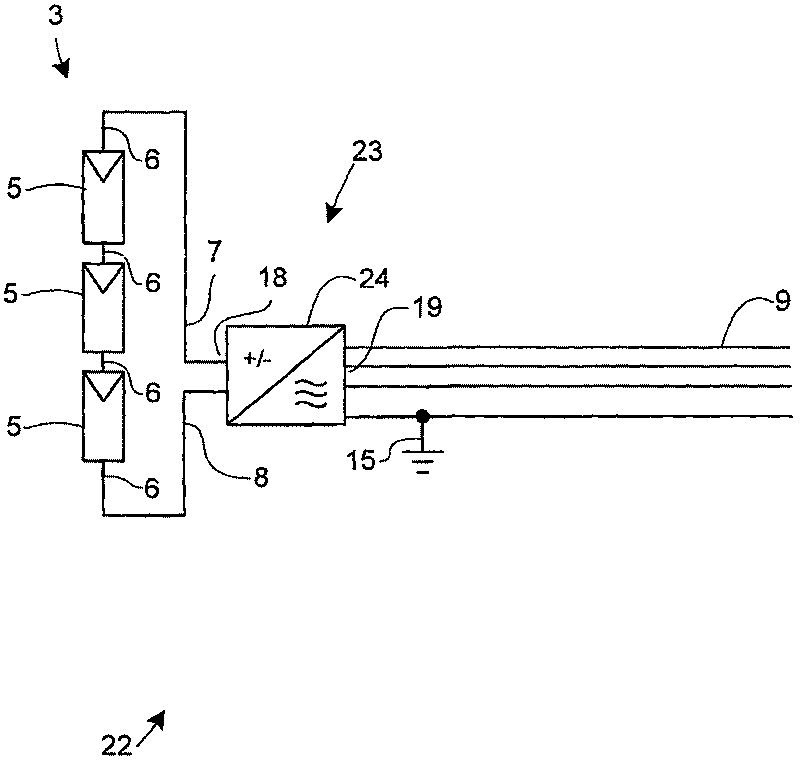

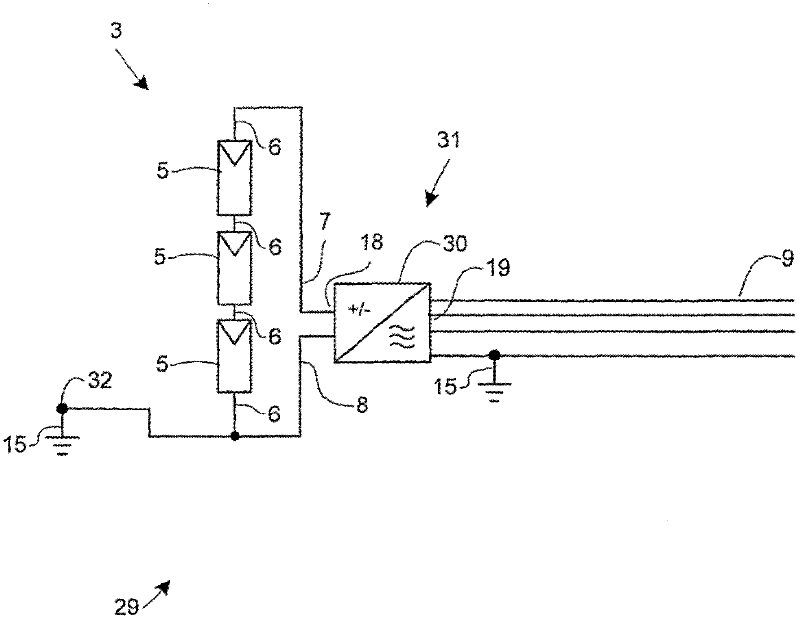

[0051] Figure 7 The PV power station 34 includes a PV generator 2 including a PV string 3 and a converter 4 . The converter 4 has a DC input 18 and a three-phase AC output 19 . The converter 4 includes a balancing circuit such that the DC potential at the DC input 18 of the converter 4 is symmetrical around the average DC potential at the AC output 19 thereof. In its simplest form, a balancing circuit may comprise a voltage divider based on resistors, inductors and / or capacitors. The PV string 3 comprises three PV modules 5 connected in series and configured such that they will be exposed to sunlight. Each PV module 5 includes several PV cells (not shown) connected as known in the art so that they produce a single DC power output at terminals 6 of the PV module 5 . The PV string 3 is electrically connected to the DC input 18 of the converter 4 via a positive connection 7 and a negative connection 8 . The AC output 19 is electrically paralleled to the grid 9 via a three-ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com