Roller press and high pressure roller mill combination set roller shaft

A high-pressure roller mill and roller press technology, applied in the field of squeeze rollers, can solve the problems of harsh load and working conditions, long production cycle, difficulty in making large rollers, etc., achieve good fatigue strength and life, reduce Stress concentration factor, the effect of easy assurance of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Take the extrusion roller shaft of the 2-meter-diameter series roller press (or high-pressure roller mill) as an example. The diameter of the roller is 200cm, and the last numbers 60, 80, 100, 120...indicate the width of the squeeze roller in cm).

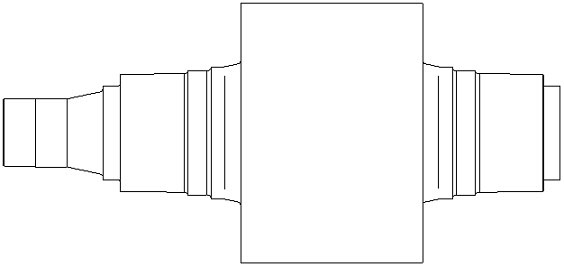

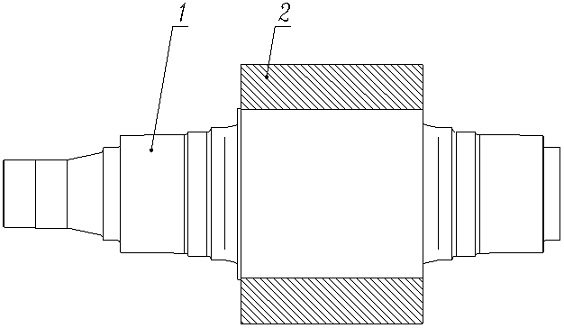

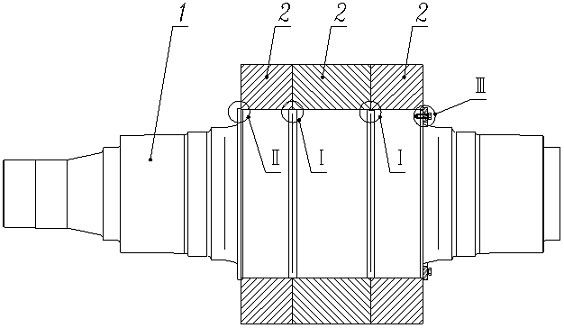

[0027] If press figure 1 For the production of the traditional overall roller structure, it is necessary to organize the production of 20060, 20080, 200100, 200120, 200140, 200160 rollers separately, and they cannot be borrowed from each other. The diameter of the 200160 rollers can reach 2 meters, and the width of the extrusion surface can be Up to 1.6 meters, such a large roller has high requirements on manufacturing equipment and technology, and it is difficult to guarantee the mechanical properties. It is difficult to realize the serialization, modularization and large-scale production of rollers, and the manufacturing cycle is long, which restricts the roller. Machine (or high pressure roller mill) production.

[0028...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com