Suspension device for mining vehicles

A suspension device, mining vehicle technology, applied in the direction of suspension, elastic suspension, vehicle parts, etc., can solve the problems of harsh working conditions, reduced quality and reliability of the whole vehicle, insufficient manufacturing process, etc., to reduce wear, improve Vehicle reliability and the effect of improving vehicle carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

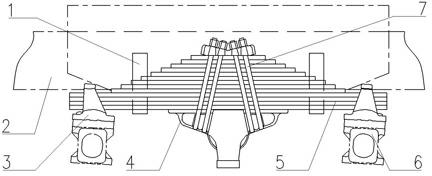

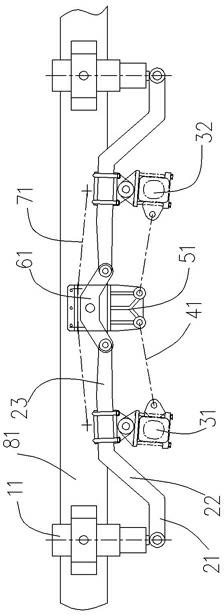

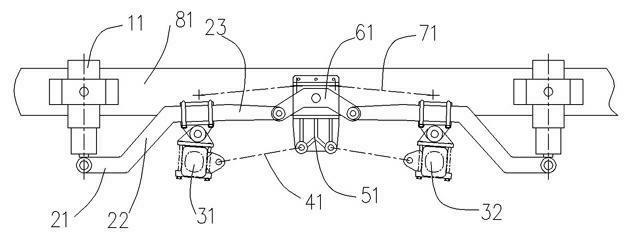

[0031] Such as figure 2 As shown, a suspension device for a mining vehicle is mainly composed of a balance arm 61, an oil-pneumatic spring 11, an elastic beam, a balance bracket 51, an upper thrust rod 71, a lower thrust rod 41 and a lateral thrust rod (not shown in the figure). , oil and gas spring 11, elastic beam, upper thrust rod 71, lower thrust rod 41 and lateral thrust rod are two.

[0032] in:

[0033] The balance arm 61 is V-shaped, and its spine is hinged on the vehicle frame 81 between the double rear axles (rear axle I 31 and rear axle II 32 shown in the figure). Preferably, the balance arm 61 is arranged in an inverted V shape. Preferably, the distance between the hinge point and the double rear axle is approximately equal.

[0034] The two oil-pneumatic springs 11 are respectively located outside the double rear axles. In other words, the double rear axles are located between the two oil-pneumatic springs 11 , and the outer cylinders of the oil-pneumatic spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com