A kind of method that graphene oxide reduction prepares graphene material

A technology of graphene and graphene, which is applied in the field of efficient reduction of graphene oxide and efficient preparation of graphene materials, can solve problems such as high cost and environmental pollution, and achieve the effects of simple method, low-cost reduction, excellent electrical conductivity and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

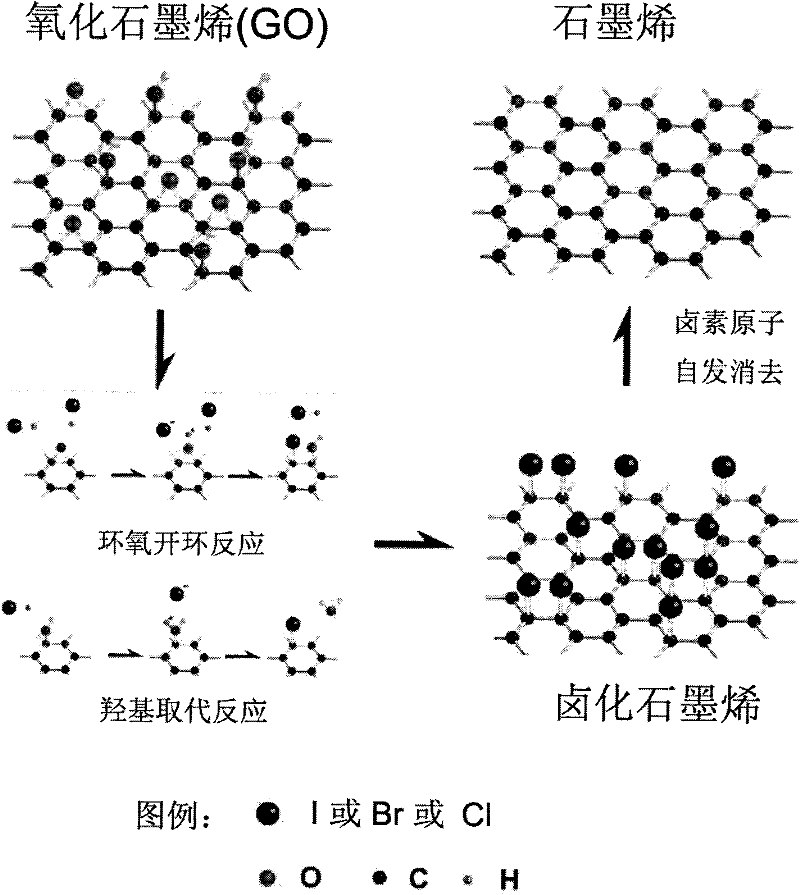

Method used

Image

Examples

Embodiment 1

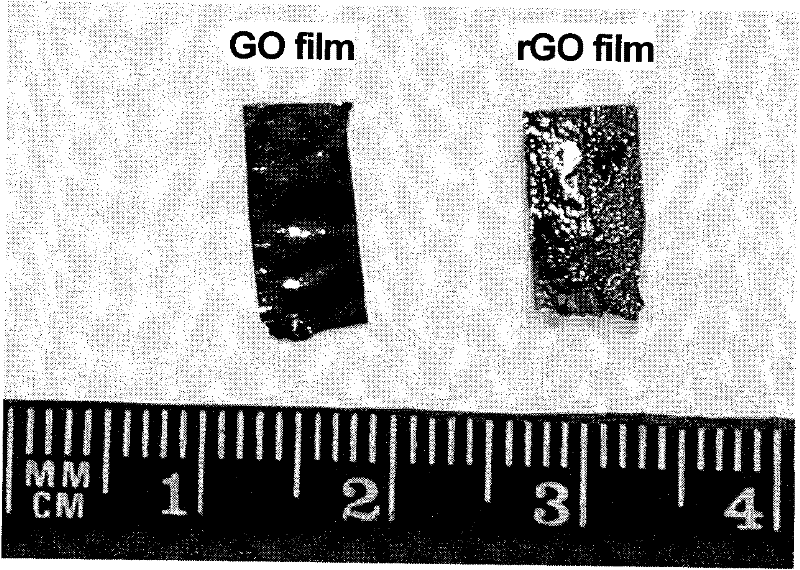

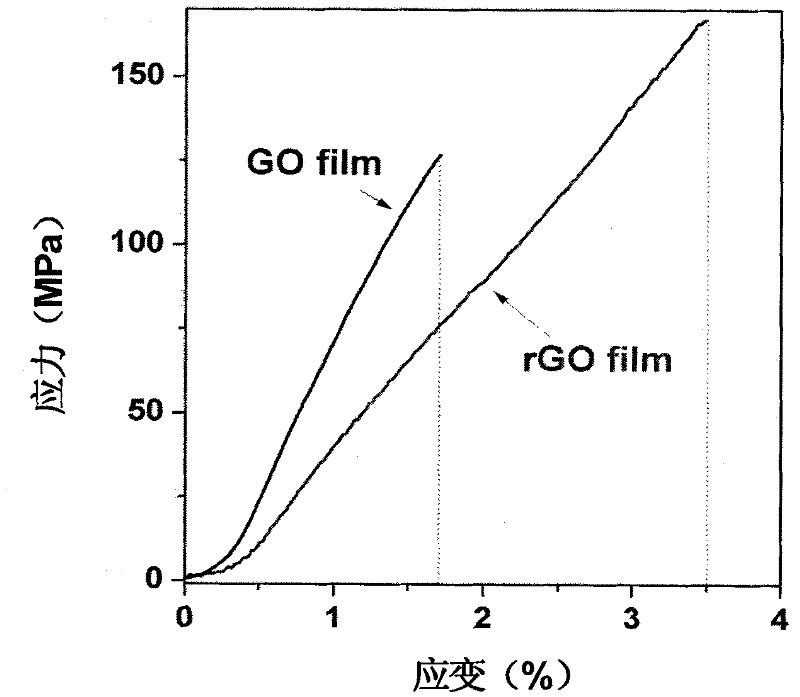

[0025] The sample to be reduced is a self-assembled GO film, and its length × width × thickness=12mm × 5mm × 0.05mm; the reducing agent is hydroiodic acid with a concentration of 55% (mass fraction); the reduction temperature is 80°C; the reduction time is 1 hour, The size of the obtained graphene film is 12mm×5mm×0.03mm. After reduction, the film changed from an insulating state to a high conductance state, and the bulk conductivity was 298S / cm. Due to the increase in electrical conductance, the reduced film exhibits a bright metallic luster (see attached figure 2 ). At the same time, the reduction process maintains the integrity and flexibility of the film; the mechanical performance test before and after reduction shows that the tensile strength of the film is significantly improved. The tensile strength of the film before reduction is 128MPa, and the tensile strength after reduction increases to 167MPa. The increase is about 30% (see attached image 3 ). X-ray photoel...

Embodiment 2

[0027] The sample to be reduced is a self-assembled GO film, and its length × width × thickness=12mm × 5mm × 0.05mm; the reducing agent is hydrobromic acid with a concentration of 40% (mass fraction); the reduction temperature is 100°C; the reduction time is 5 hours, The size of the obtained graphene film is 12mm×5mm×0.04mm. The volume conductivity of the film after reduction was 258S / cm, and the tensile strength increased from 122MPa to 147MPa. The C / O of the GO film before reduction was 2.4, and the C / O increased to 10.8 after reduction (see attached Figure 5 ).

Embodiment 3

[0029] The sample to be reduced is GO paper obtained by filtration, and its length×width×thickness=12mm×5mm×0.5mm; the reducing agent is thionyl chloride liquid; the reduction temperature is 70°C; the reduction time is 24 hours, and the obtained graphene paper The specification is 12mm×5mm×0.45mm. After reduction, the volume conductivity of the film is 18S / cm, and the tensile strength increases from 112MPa to 124MPa. The C / O of GO paper before reduction was 2.3, and the C / O increased to 4.6 after reduction (see attached Figure 6 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com