Method for treating sewage produced during cyclohexanone production by adopting extraction method

A technology of cyclohexanone and extraction method is applied in the field of treating sewage generated in the production of cyclohexanone, which can solve the problems of insufficient effect and high operating cost, and achieve the effects of reducing treatment load, low operating cost and reducing organic matter concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

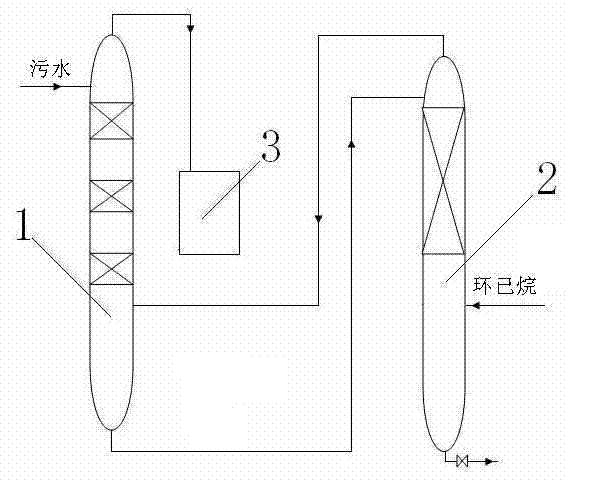

Image

Examples

Embodiment 1

[0012] Example 1: Pump sewage with a COD value of 16191mg / kg into the top of the second extraction tower 2, with a flow rate of 11.5m 3 / h. Control the flow rate of the extractant hexanaphthene that is pressed into the bottom of extraction tower 1 to be 5.0 m 3 / h. The measured COD values of the sewage at the inlet and outlet of the second extraction tower 2 are 16191mg / kg and 3524mg / kg respectively, and the calculated COD extraction rate is 78.2%; The total extraction rate of COD was 94.5%.

Embodiment 2

[0013] Embodiment 2: Pump sewage with a COD value of 17257mg / kg into the top of the second extraction tower 2, with a flow rate of 11.5m 3 / h. Control the flow rate of the extraction agent cyclohexane that is pressed into the bottom of the extraction tower 1 to be 6.0 m 3 / h. The measured COD values of the sewage at the inlet and outlet of the second extraction tower 2 are 17257mg / kg and 3169mg / kg respectively, and the calculated COD extraction rate is 81.6%; The total extraction rate of COD was 95.0%.

Embodiment 3

[0014] Example 3: Pump sewage with a COD value of 16358mg / kg into the top of the second extraction tower 2, with a flow rate of 11.5m 3 / h. Control the flow rate of the extractant hexanaphthene that is pressed into the bottom of extraction tower 1 to be 8.0 m 3 / h. The measured COD values of the sewage at the inlet and outlet of the second extraction tower 2 are 16358mg / kg and 2640mg / kg respectively, and the calculated COD extraction rate is 83.9%; The total extraction rate of COD was 96.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com