A kind of production method of chemical fiber grade cyclohexanone

A production method and cyclohexanone technology are applied in the production field of chemical fiber grade cyclohexanone, can solve the problems of increased ton ketone benzene consumption, increased production cost, increased ton ketone energy consumption, etc., and achieve low material consumption, strong removal capacity, The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

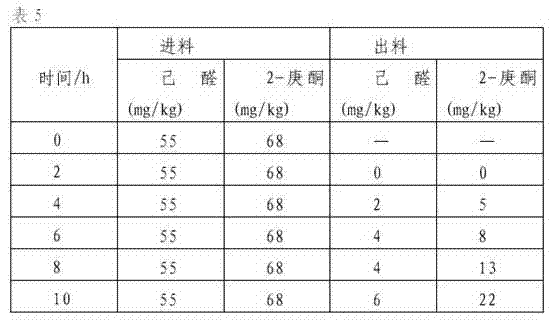

[0015] The specifications of the adsorption column are: column height: 1000mm, inner diameter: 50mm, volume: 1.96L. 1400g molecular sieves are loaded into the adsorption column. Pass the cyclohexanone solution from the bottom of the adsorption column, the content of hexanal in the solution is 70mg / kg, the content of 2-heptanone is 100mg / kg, the flow rate of cyclohexanone is about 2.2L / h, and the total feed volume is 58L. The adsorption data are shown in Table 1:

[0016]

[0017] After the adsorption test, the cyclohexanone vapor at 160° C. is used for desorption, and the cyclohexanone vapor contains less than 30 mg / kg of the total amount of hexanal and 2-heptanone. The cyclohexanone vapor is introduced from the top of the adsorption column, and the condensate is discharged from the bottom, and the whole desorption lasts for 26 minutes.

[0018] After the desorption was completed, when the temperature dropped to room temperature, the adsorption test was carried o...

Embodiment 2

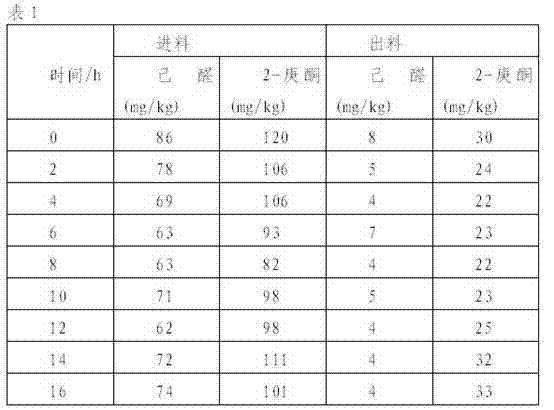

[0022] The specifications of the adsorption column are: column height: 1000mm, inner diameter: 50mm, volume: 1.96L. Add 1204g molecular sieves to the adsorption column. Pass through the cyclohexanone solution from the bottom of the adsorption column, which contains 100 mg / kg of hexanal and 60 mg / kg of 2-heptanone. The flow rate of cyclohexanone is about 65ml / min. The adsorption data are shown in Table 3:

[0023]

[0024] After the adsorption test, the cyclohexanone vapor at 160° C. was used for desorption, and the cyclohexanone vapor contained the total amount of hexanal and 2-heptanone less than 36 mg / kg. The cyclohexanone vapor is introduced from the top of the adsorption column, and the condensate is discharged from the bottom, and the whole desorption lasts for 60 minutes.

[0025] After the desorption was completed, when the temperature dropped to room temperature, the adsorption test was carried out again. The test method was the same as the above method, and t...

Embodiment 3

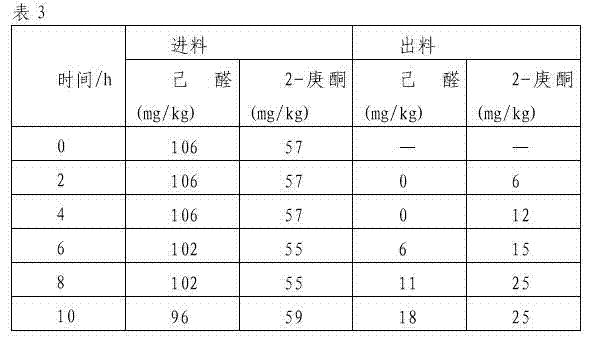

[0029] The specifications of the adsorption column are: column height: 1000mm, inner diameter: 50mm, volume: 0.35L. Add 251g molecular sieves to the adsorption column. Pass into cyclohexanone solution from the bottom of the adsorption column, wherein containing hexanal is 55mg / kg, and 2-heptanone is 68mg / kg. The flow rate of cyclohexanone is about 5.6ml / min. The adsorption data are shown in Table 5:

[0030]

[0031] After the adsorption test, the cyclohexanone vapor at 160° C. was used for desorption, and the cyclohexanone vapor contained the total amount of hexanal and 2-heptanone less than 36 mg / kg. The cyclohexanone vapor is introduced from the top of the adsorption column, and the condensate is discharged from the bottom, and the whole desorption lasts for 60 minutes.

[0032] After the desorption was completed, when the temperature dropped to room temperature, the adsorption test was carried out again. The test method was the same as the above method, and the data ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com