Method for purifying epigallo catechin gallate (EGCG)

A technology of epigallocatechin and gallate, which is applied in the field of separation and purification of effective components of natural plants, can solve the problems of time-consuming, non-continuous automatic production, and low utilization rate of adsorbents, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

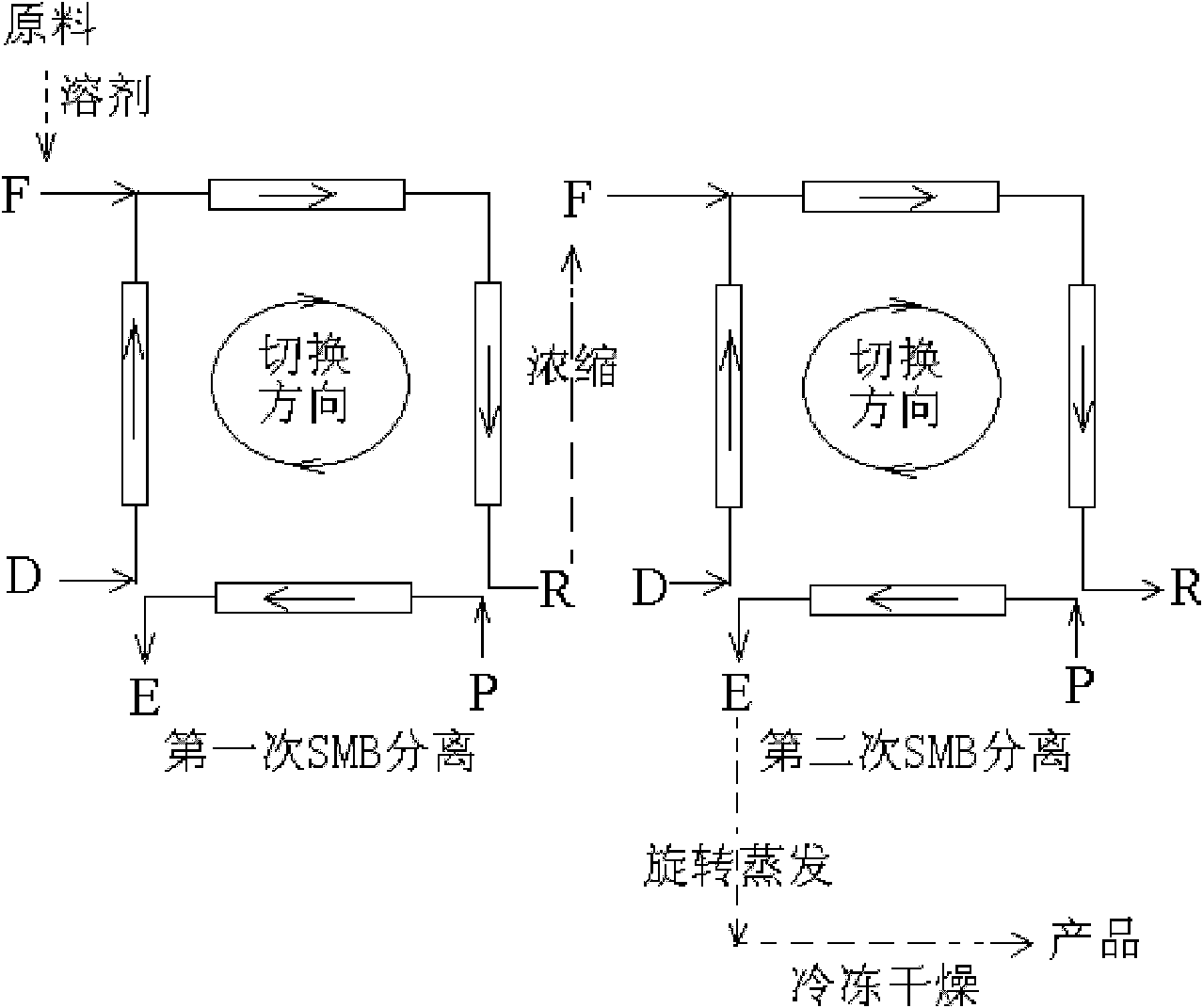

Method used

Image

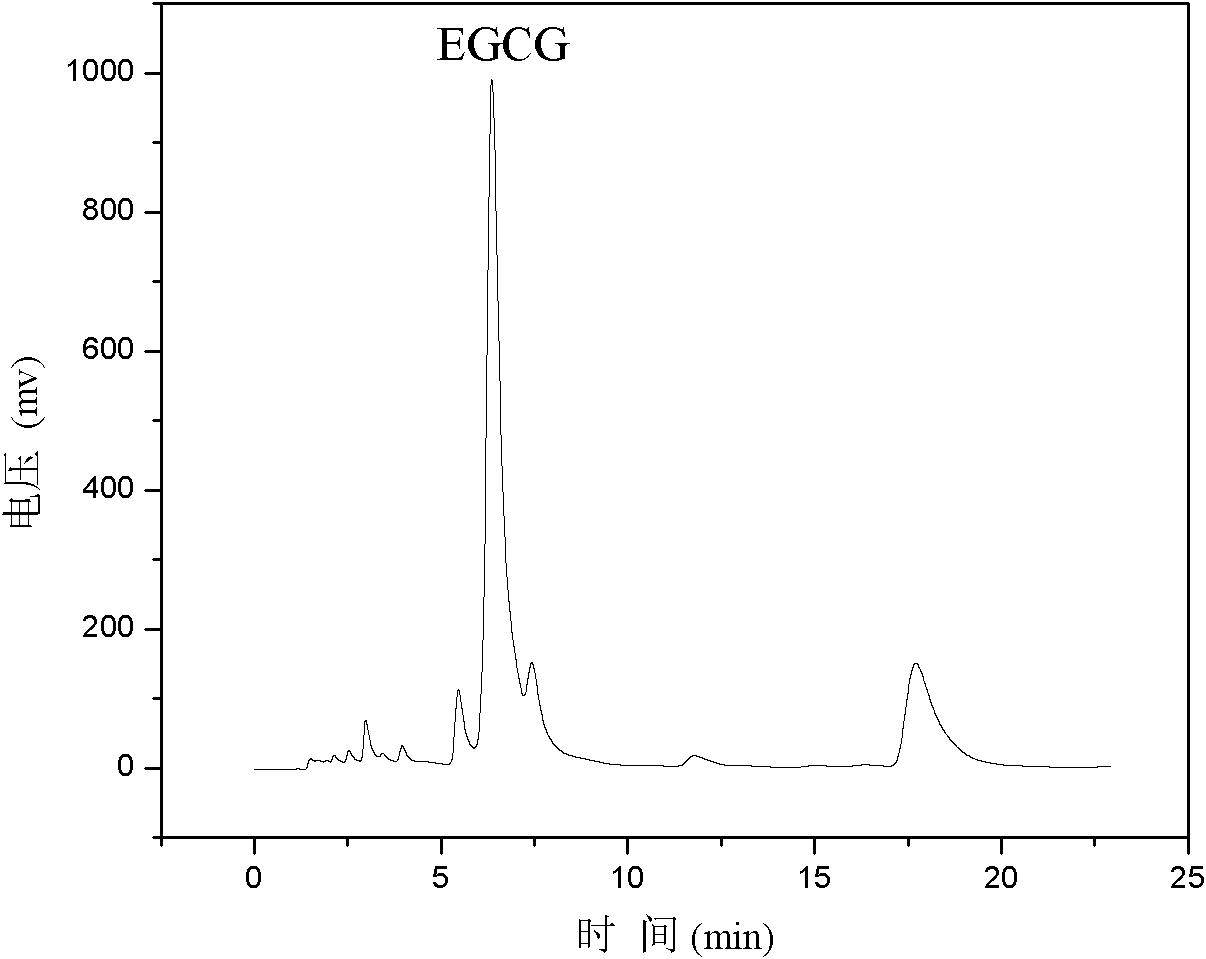

Examples

Embodiment 1

[0035] (1) SMB device

[0036] 8 chromatographic columns, mobile phase D delivery pump flow rate 0-10mL / min, pressure 0-10Mpa; material liquid F pump flow rate 0-30mL / h, pressure 0-8Mpa; mobile phase P delivery pump flow rate 0-10mL / min, Pressure 0-10Mpa, 48 automatic control valves, a set of single-chip automatic control system, 5 liquid storage tanks (mobile phase D, raw material F, mobile phase P, extract E, raffinate R each need a liquid storage tank) , multi-pass, pipelines, connectors, computer; the chromatographic column is 10cm×1cm; the stationary phase uses octadecylsilane bonded silica gel ODS, 20-30μm.

[0037] (2) SMB working conditions

[0038] The first SMB working conditions are as follows:

[0039] SMB operation mode: set the total number of columns of the SMB system to N=4, set the SMB elution zone to 1 chromatographic column, the refining zone to 1 chromatographic column, the adsorption zone to 2 chromatographic columns, and the operating mode is 1-1-2;

...

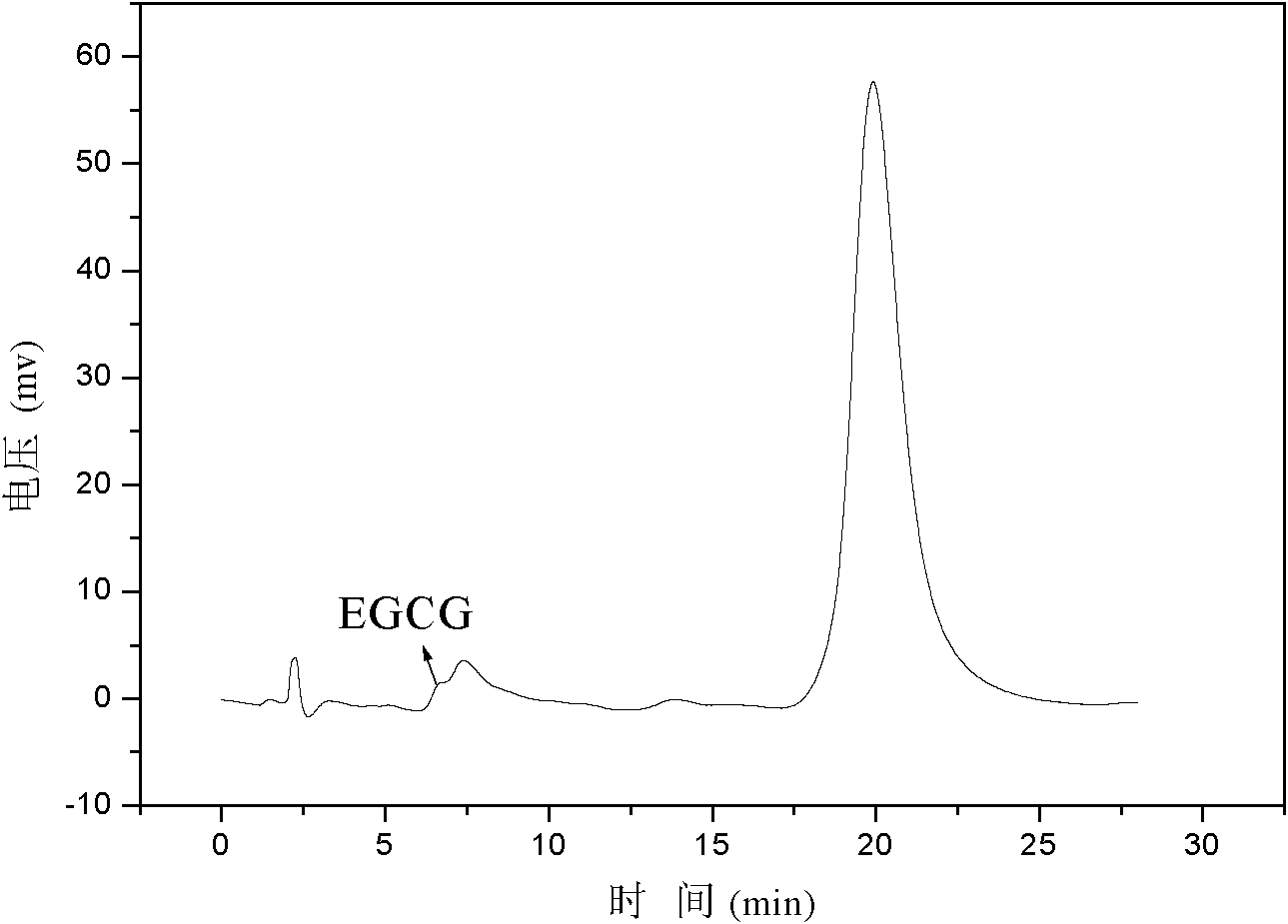

Embodiment 2

[0055] (1) SMB equipment: same as embodiment 1.

[0056] (2) SMB working conditions

[0057] The first SMB working conditions are as follows:

[0058] SMB operation mode: set the total number of columns of the SMB system to N=5, set the SMB elution zone to 1 chromatographic column, the refining zone to 2 chromatographic columns, the adsorption zone to 2 chromatographic columns, and the operating mode is 1-2-2;

[0059] Mobile phase composition: the mobile phase D of the refining zone and the adsorption zone is a mixed solution of ethanol and water, and the volume percentage of ethanol is C D is 15%; the mobile phase P of the elution band is ethanol;

[0060] Mobile phase flow rate: In the elution zone, eluent P flow rate U p is 3.8cm / min, the flow rate of extract E is U E =U p ; In the polishing zone and the adsorption zone, the eluent D flow rate U D is 2.9cm / min, the flow rate of the sample fluid F is U F 0.25cm / min, raffinate R flow rate U R =U D + U F .

[0061]...

Embodiment 3

[0073] (1) SMB equipment: same as embodiment 1.

[0074] (2) SMB working conditions

[0075] The first SMB working conditions are as follows:

[0076] SMB operation mode: set the total number of columns of the SMB system to N=6, set the SMB elution zone to 1 chromatographic column, the refining zone to 3 chromatographic columns, the adsorption zone to 2 chromatographic columns, and the operating mode is 1-3-2;

[0077] Mobile phase composition: the mobile phase D of the refining zone and the adsorption zone is a mixed solution of ethanol and water, and the volume percentage of ethanol is C D is 15%; the mobile phase P of the elution band is ethanol;

[0078] Mobile phase flow rate: In the elution zone, eluent P flow rate U p is 5.1cm / min, the flow rate of extract E is U E =U p ; In the polishing zone and the adsorption zone, the eluent D flow rate U D is 2.9cm / min, the flow rate of the sample fluid F is U F 0.25cm / min, raffinate R flow rate U R =U D + U F .

[0079]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com