Rare earth luminescent material and its preparation method

A rare earth luminescence and rare earth technology, applied in the field of luminescent materials containing rare earth elements and their preparation, can solve the problem that the luminous efficiency of phosphors needs to be further improved and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The preparation method of the above-mentioned rare earth luminescent material comprises the following steps:

[0021] (1) The metal nanoparticles are surface-treated, that is, at least one of gold (Au), silver (Ag), platinum (Pt), palladium (Pd) and copper (Cu) metal nanoparticles is added to the polyvinylpyrrolidone solution, stir well.

[0022] (2) Add Al to the above solution 3+ solution and surfactant, stir well. Among them, the Al 3+ The solution is preferably AlCl 3 solution, Al 2 (SO 4 ) 3 solution, Al(NO 3 ) 3 at least one of the solutions. The surfactant is at least one of polyethylene glycol, ethylene glycol, isopropanol and polyvinyl alcohol, preferably polyethylene glycol with a molecular weight of 2000-10000.

[0023] (3) Slowly add the precipitating agent dropwise under the condition of a water bath at 0-100°C, stir for 1.5-5 hours, then age, then filter, wash and dry the precipitate. Among them, the precipitating agent is NH 4 HCO 3 , NH 3 h...

Embodiment 1

[0030] At room temperature, weigh 0.30 g of polyvinylpyrrolidone (PVP) and dissolve it in 5 mL of deionized water, then add 6 mL of 1×10 -2 mol / L platinum nanoparticles, stirred for 18h, then added 12mL of 1mol / L AlCl while stirring 3 , isopropanol 5mL, after stirring evenly, slowly add 30mL 4mol / LNH 4 HCO 3 , stirred and reacted for 5 hours, and then aged for a certain period of time. The precipitate was filtered, washed, dried, and heat-treated at 500°C for 8 hours to obtain Al 2 o 3Pt powder, where Al:Pt=1:5×10 -3 . Then weigh 1.0698g of Y 2 (CO 3 ) 3 , 0.5098g Al 2 o 3 Pt, Ce at 0.0046g 2 (CO 3 ) 3 , placed in an agate mortar and ground until well mixed, then transferred the powder to a corundum crucible, and placed in a tube furnace at 95% N 2 plus 5%H 2 Burn at 1700°C for 2 hours in a weak reducing atmosphere, cool to room temperature, and grind into powder to get Y 2.99 Ce 0.01 al 5 o 12 Pt luminescent material.

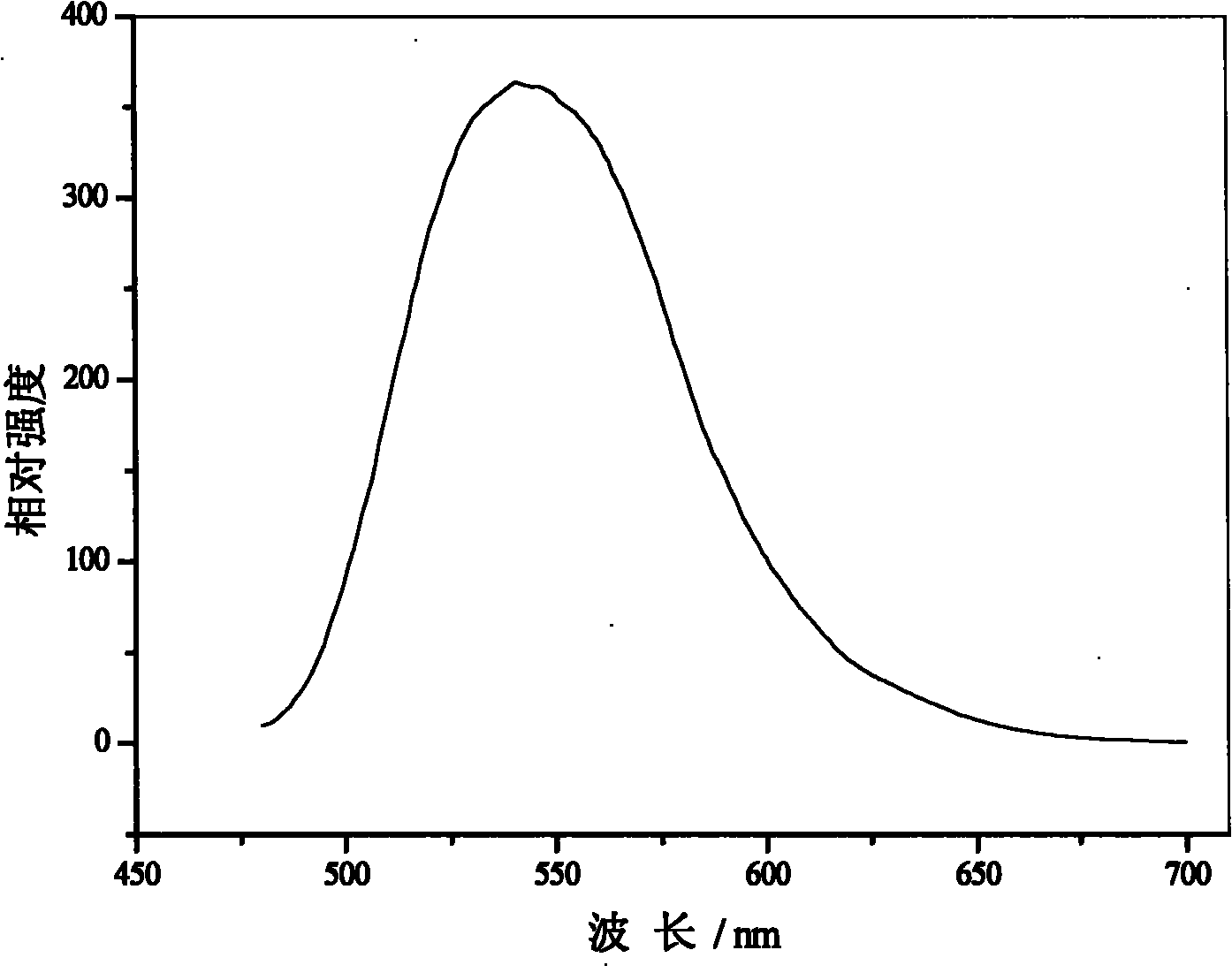

[0031] Such as figure 1 Shown as Y ...

Embodiment 2

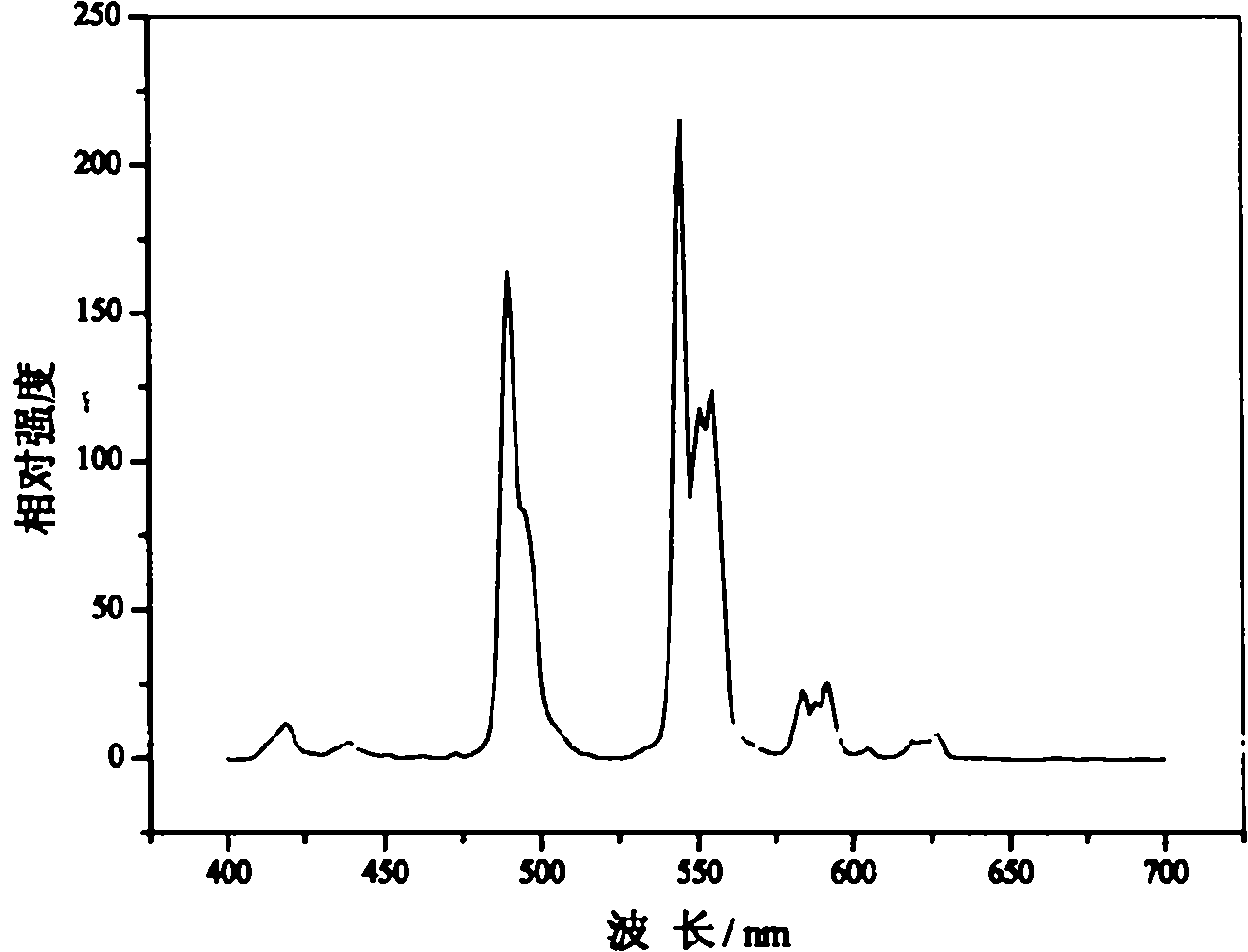

[0033] At room temperature, weigh 0.1g PVP and dissolve it in 4mL deionized water, dissolve, then add 6mL1×10 -3 mol / L Ag nanoparticles, stirred for 12h, then added 6mL 2mol / L Al(NO 3 ) 3 , 6mL of 4% (V / V) polyvinyl alcohol aqueous solution, after stirring evenly, slowly add NH 3 h 2 O, until pH = 9, stirred for 3 hours, and then aged for a certain period of time. The precipitate was filtered, washed, dried, and heat-treated at 900°C for 4 hours to obtain Al 2 o 3 Ag powder, where Al:Ag=1:2.5×10 -4 . Then weigh 0.6322g of Y 2 o 3 , 0.5098g Al 2 o 3 Ag, 0.0275g CeO 2 , 0.0448g Tb 4 o 7 Put it in an agate mortar and grind until it is evenly mixed, then transfer the powder to a corundum crucible, reduce it with carbon powder in a muffle furnace, burn it at 1500°C for 4 hours, cool it to room temperature, and grind it into a powder to get Y 2.80 Tb 0.12 Ce 0.08 al 5 o 12 Ag luminescent material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com