Design method of improved scram combustion chamber and its swirler

A technology of scramjet combustion chamber and combustion chamber, which is applied in mechanical equipment, ramjet engines, etc., can solve the problems of increasing engine mass load, reducing thrust-to-weight ratio of scramjet engine, and large total pressure loss, and reducing the weight of the engine. , the effect of improving combustion efficiency and increasing thrust-to-weight ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to enable the public to fully understand the technical essence and beneficial effects of the present invention, the applicant will describe in detail the specific implementation of the present invention below in conjunction with the accompanying drawings, but the applicant's description of the embodiments is not a limitation to the technical solution. Changes in the form of the inventive concept rather than in substance should be regarded as the protection scope of the present invention.

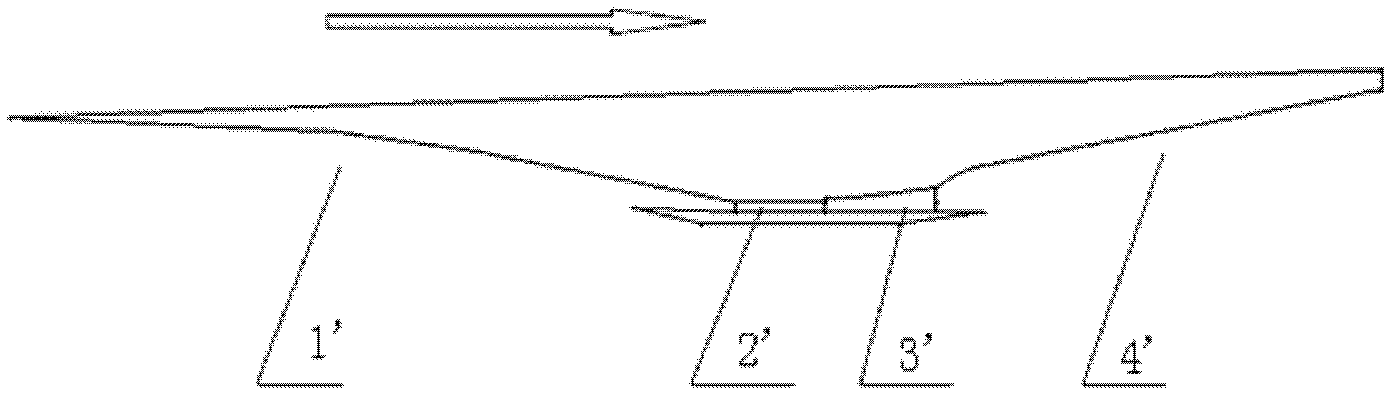

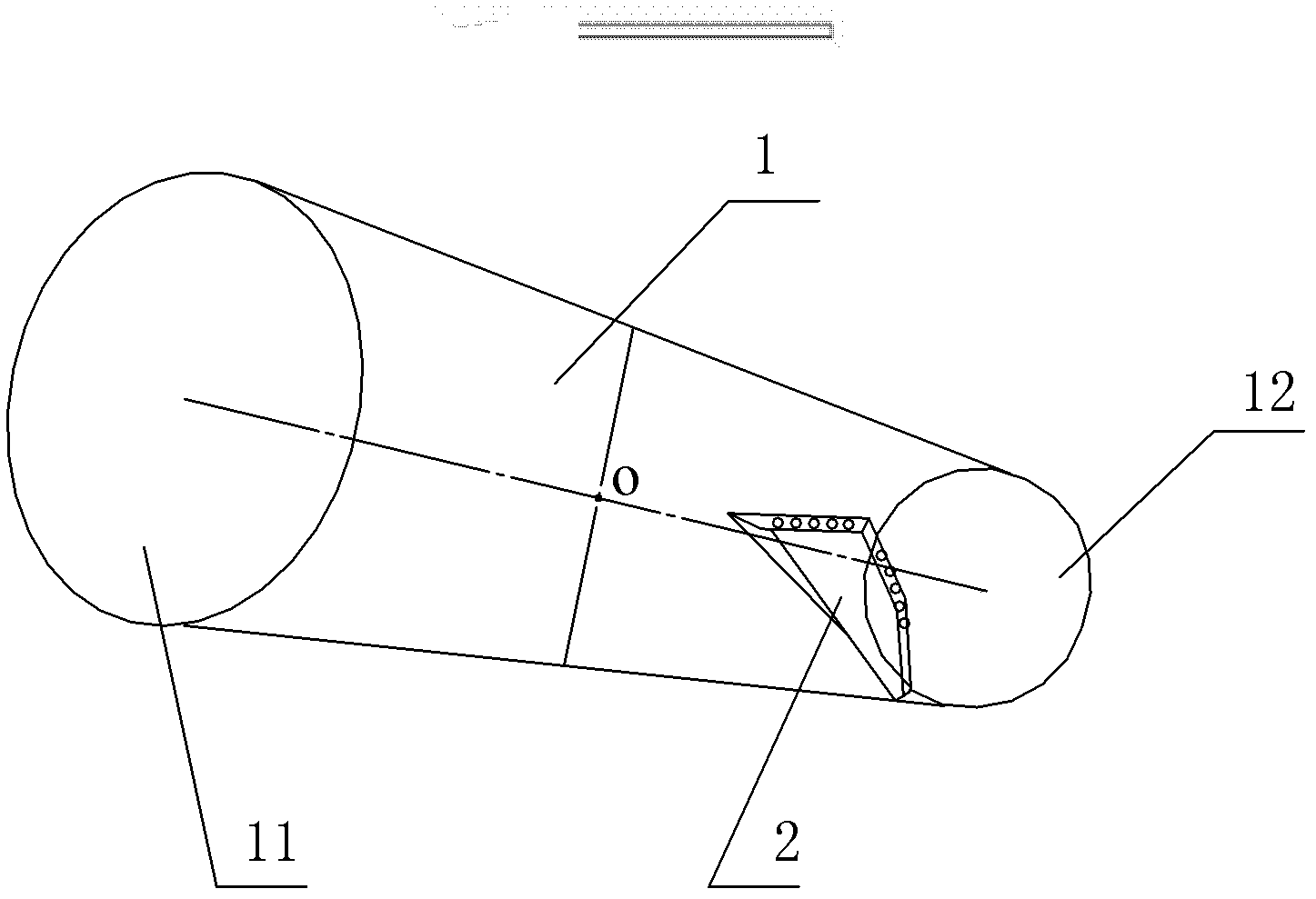

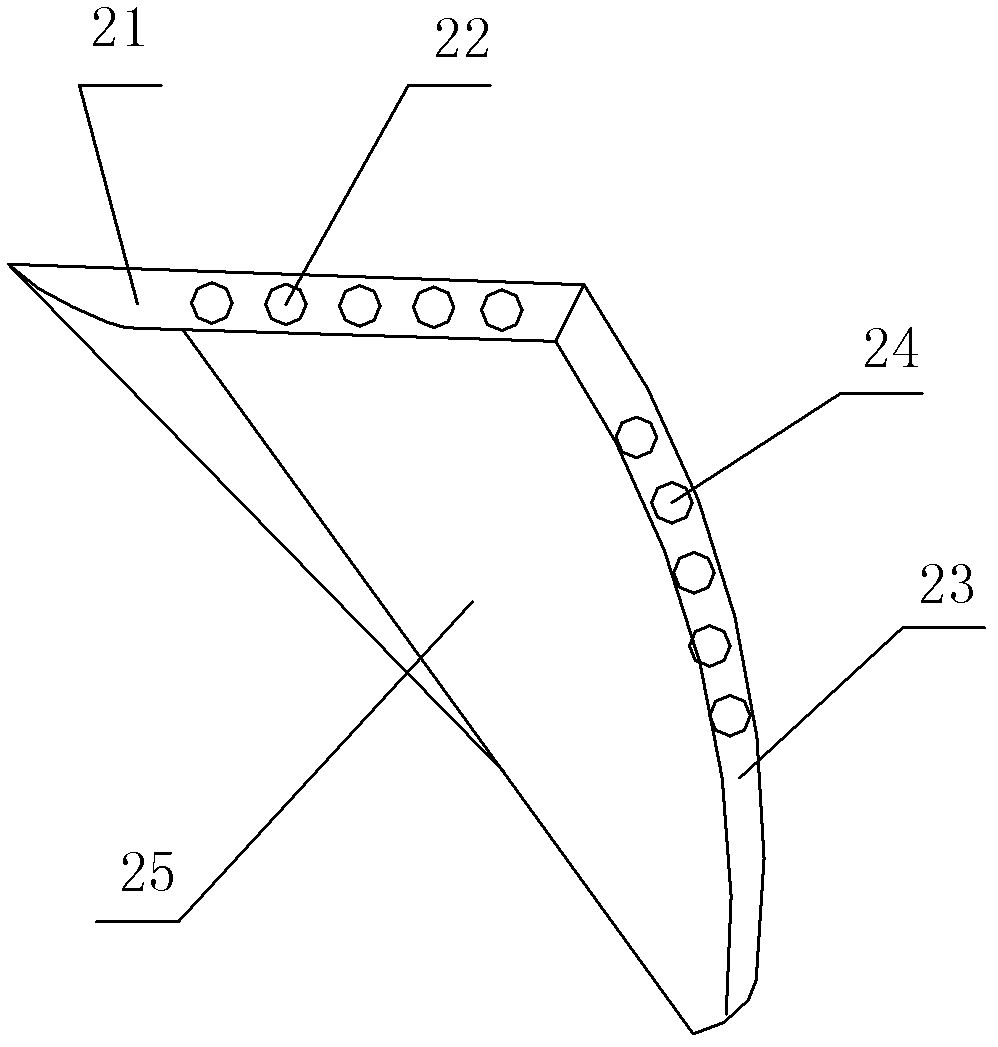

[0025] Such as Figures 2 to 5 As shown, the improved super-combustion combustion chamber of the present invention includes a combustion chamber 1, the cross section of the inner flow channel of the combustion chamber 1 is circular or elliptical, and a device that causes air flow is installed near the inlet of the inner flow channel of the combustion chamber 1. The swirler 2 that spirally moves; the swirler 2 includes a swirl generating upper wall plate 26 that makes the air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com