A dry double clutch

A dual-clutch, clutch technology, applied in the direction of clutches, fluid-driven clutches, non-mechanical-driven clutches, etc., can solve the problems of unfavorable dry-type dual-clutch commercialization, long input shaft length of transmission, and difficult maintenance of dual-clutches, etc., to achieve replacement Easy maintenance, simplified clutch structure, and reduced transmission process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the drawings and embodiments:

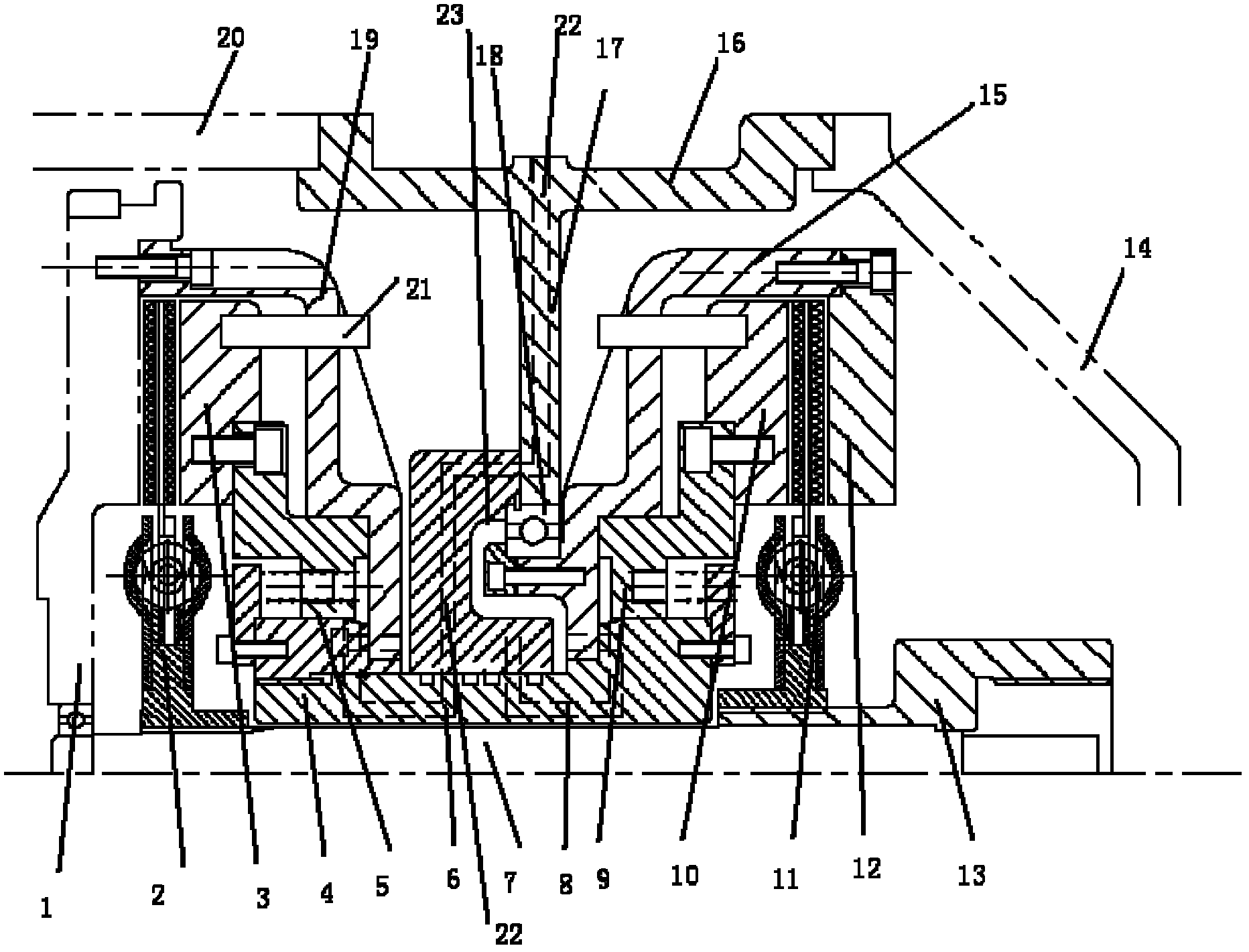

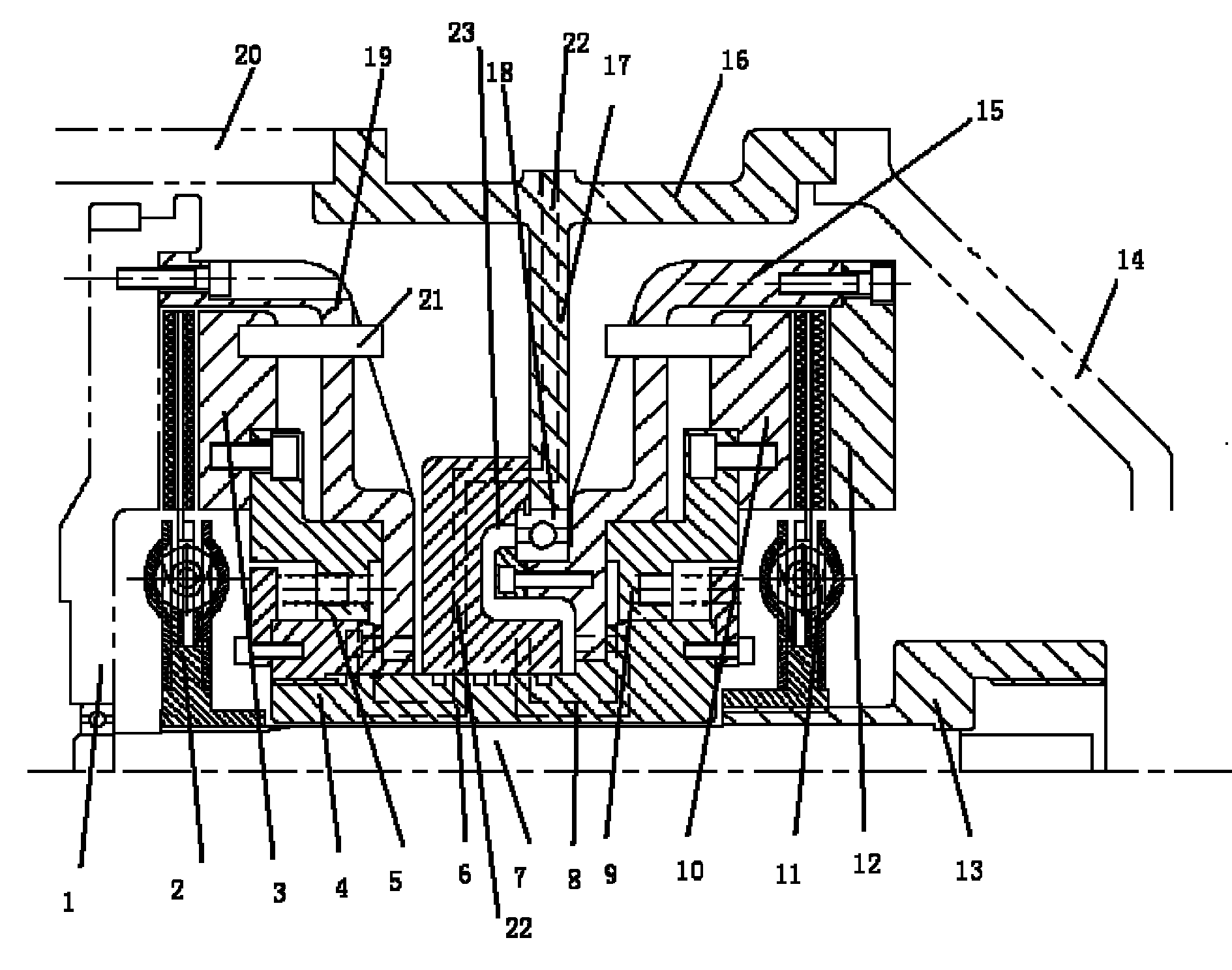

[0019] Such as figure 1 A dry dual clutch is shown, which includes a clutch housing 14, a first clutch, a second clutch, a transition shaft 4, a first input shaft 7, and a second input shaft 13 coaxially arranged with the first input shaft 7. , The first clutch includes a first pressure plate 3, a first driven plate assembly 2 located between the first engine flywheel 1 and the first pressure plate 3, the first driven plate assembly 2 is splined to the first input shaft 7; The second clutch includes a second pressure plate 10, a second driven plate assembly 11 located between the second engine flywheel 12 and the second pressure plate 10, the second driven plate assembly 11 is splined to the second input Shaft 13, the first engine flywheel 1 and the second engine flywheel 12 are fixedly connected by a transition shaft 4, the first pressure plate 3 is control...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap