Circulating pipe network water quantity integrated simulation test system with temperature control system

A technology of temperature control system and simulation test system, which is applied in pipeline system, mechanical equipment, gas/liquid distribution and storage, etc. It can solve problems such as uncontrollable temperature, influence of four seasons temperature, large simulation distortion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

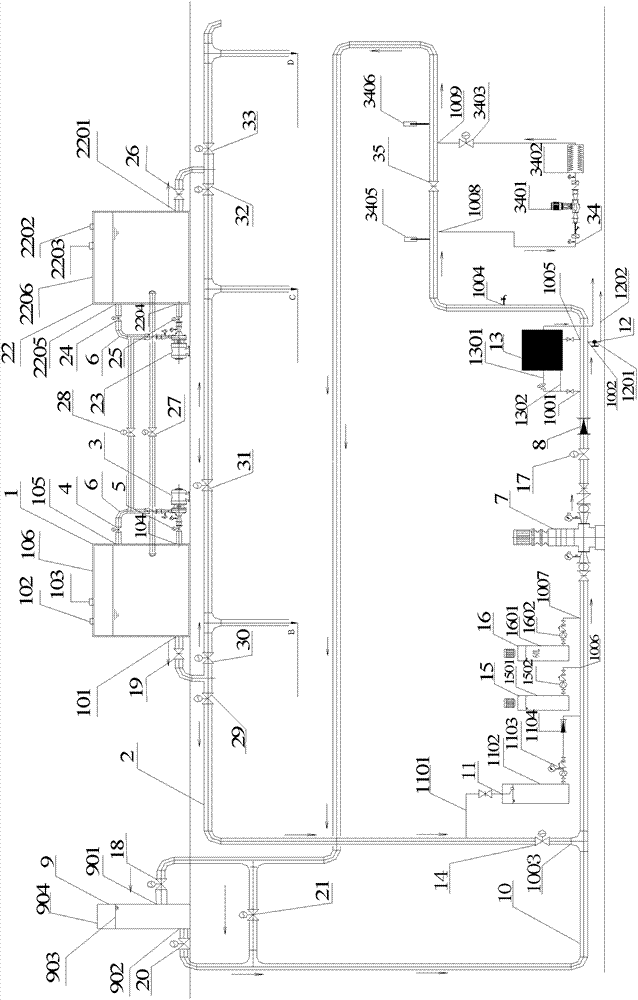

[0043] Such as figure 1 As shown, it is the water quality comprehensive simulation test system of the circulating pipe network with temperature control system of the present invention, which is composed of 1 water supply subsystem and 4 independent circulations connected with the water supply subsystem by the pipeline 2 (hereinafter referred to as pipeline 2) of the water supply subsystem The pipe network subsystem, the four independent circulation pipe network subsystems are the first independent circulation pipe network subsystem, the second independent circulation pipe network subsystem, the third independent circulation pipe network subsystem and the fourth independent circulation pipe network subsystem.

[0044] The water supply subsystem includes a first water supply tank 1, a second water supply tank 22, a pipeline 2, a first mixing circulation pump 3, a valve 4, a valve 5, a valve 19, a second mixing circulation pump 23, a valve 24, a valve 25, and a valve 26 , the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com