Optical displacement sensor

A technology of displacement sensor and sensor, which is applied in the direction of adopting optical devices, instruments, measuring devices, etc., can solve problems such as complex production, achieve the effects of eliminating influencing factors, simple structure and principle, and improving detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

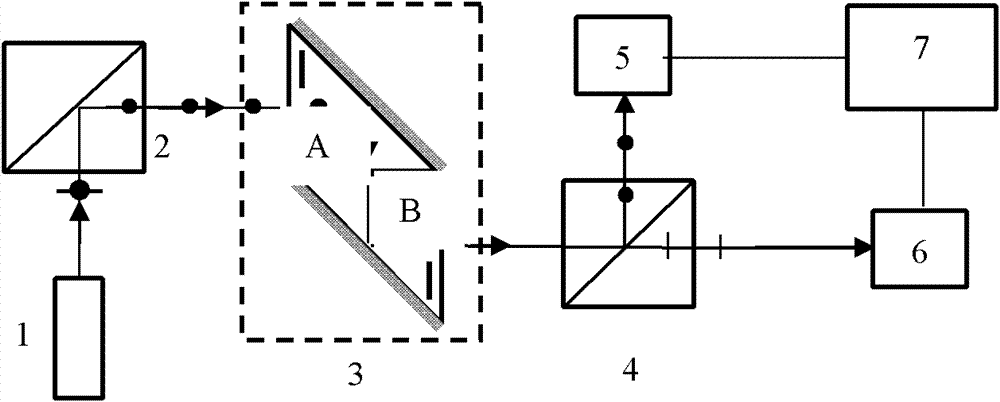

[0040] The device used in an optical displacement sensor of the present invention is as figure 1 shown. figure 1Among them, 1 is the laser. 2 is the first polarizing beam splitting prism. 3 is a displacement sensing element, which is composed of two isosceles right-angled triangle quartz crystal prisms A and B with the same structure and performance on the upper and lower sides. A and B glue their horizontal bottom surfaces together through optical glue to form a An overall sensing element; one of A and B is required to be a positive crystal, and the other is a negative crystal; the slopes are respectively coated with polarization-maintaining reflective films, so that the polarization state of the light does not change when the light is reflected on the slopes; the optical axes of crystals A and B The direction is perpendicular to its two bottom surfaces, as shown by the marking line "|" in the quartz crystal in the figure. The laser light emitted by the laser 1 is reflecte...

specific Embodiment 2

[0061] The device used in an optical displacement sensor of the present invention is as figure 1 shown. figure 1 1 is the laser. 2 is the first polarizing beam splitting prism. 3 is a displacement sensing element, which is composed of two isosceles right-angled triangle quartz crystal prisms A and B with the same structure and performance on the upper and lower sides. The two bottom surfaces of A and B are glued together by optical glue to form a The overall sensing element; one of A and B is required to be a positive crystal, and the other is a negative crystal; the slopes are respectively coated with polarization-maintaining reflective film, so that the polarization state of the light does not change when the light is reflected on the slope; the direction of the optical axis of crystals A and B It is perpendicular to its two bottom surfaces, as shown by the marking line "|" in the quartz crystal in the figure. The laser light emitted by the laser 1 is reflected by the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com