Plasma treatment device

A plasma and processing device technology, applied in the field of plasma processing devices, can solve problems such as uneven wafers, and achieve the effects of eliminating standing wave effects, uniform etching rate, and uniform energy distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

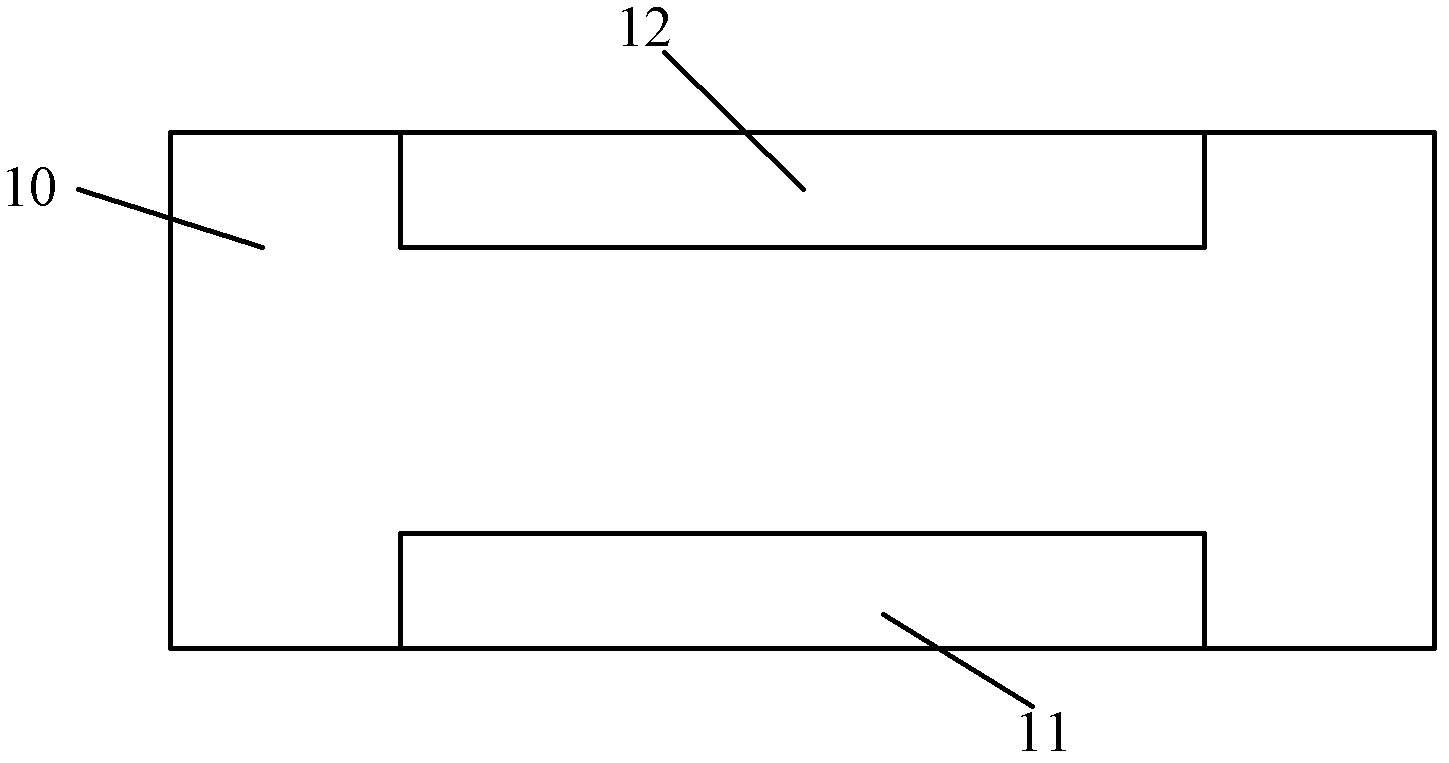

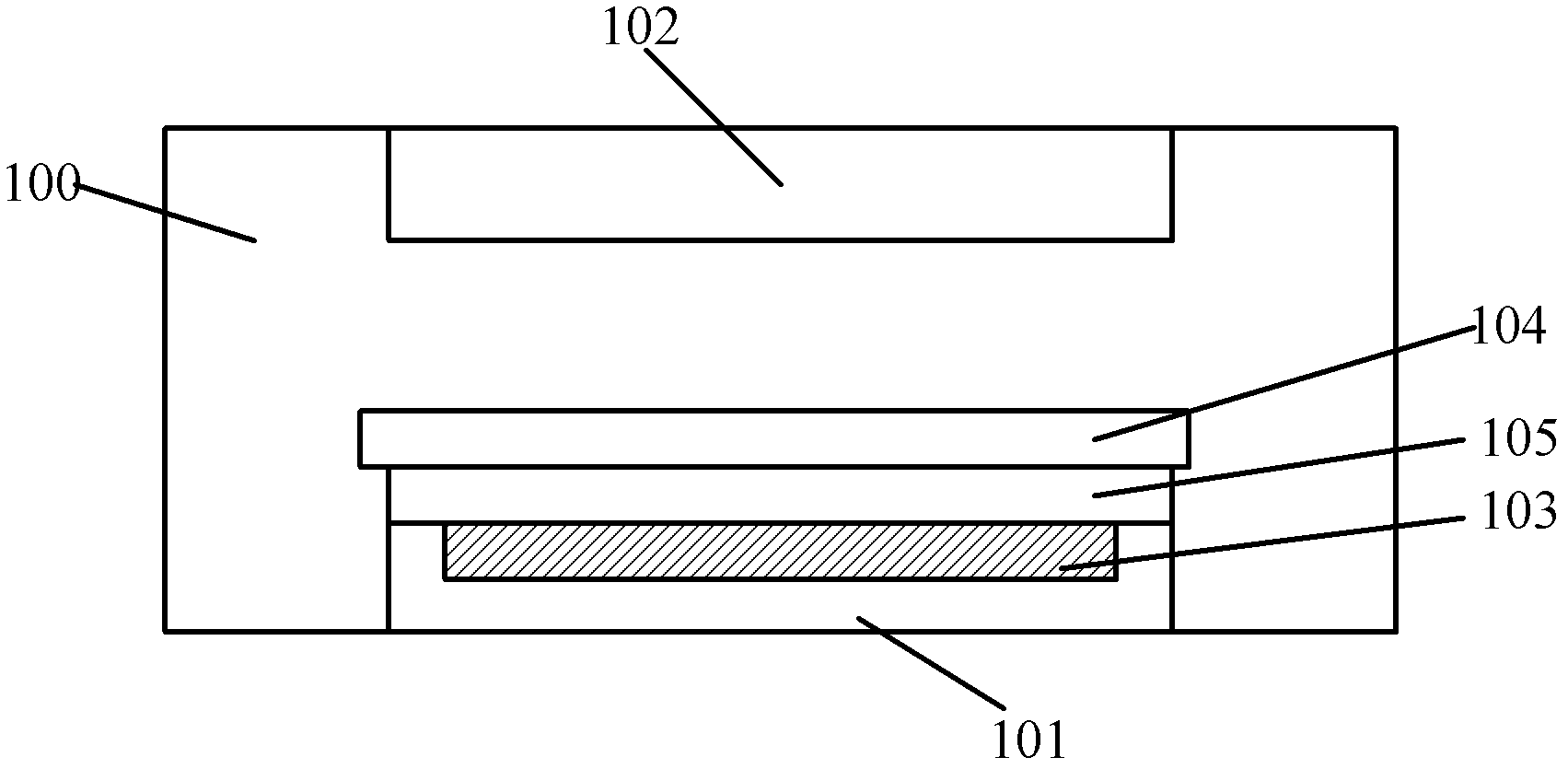

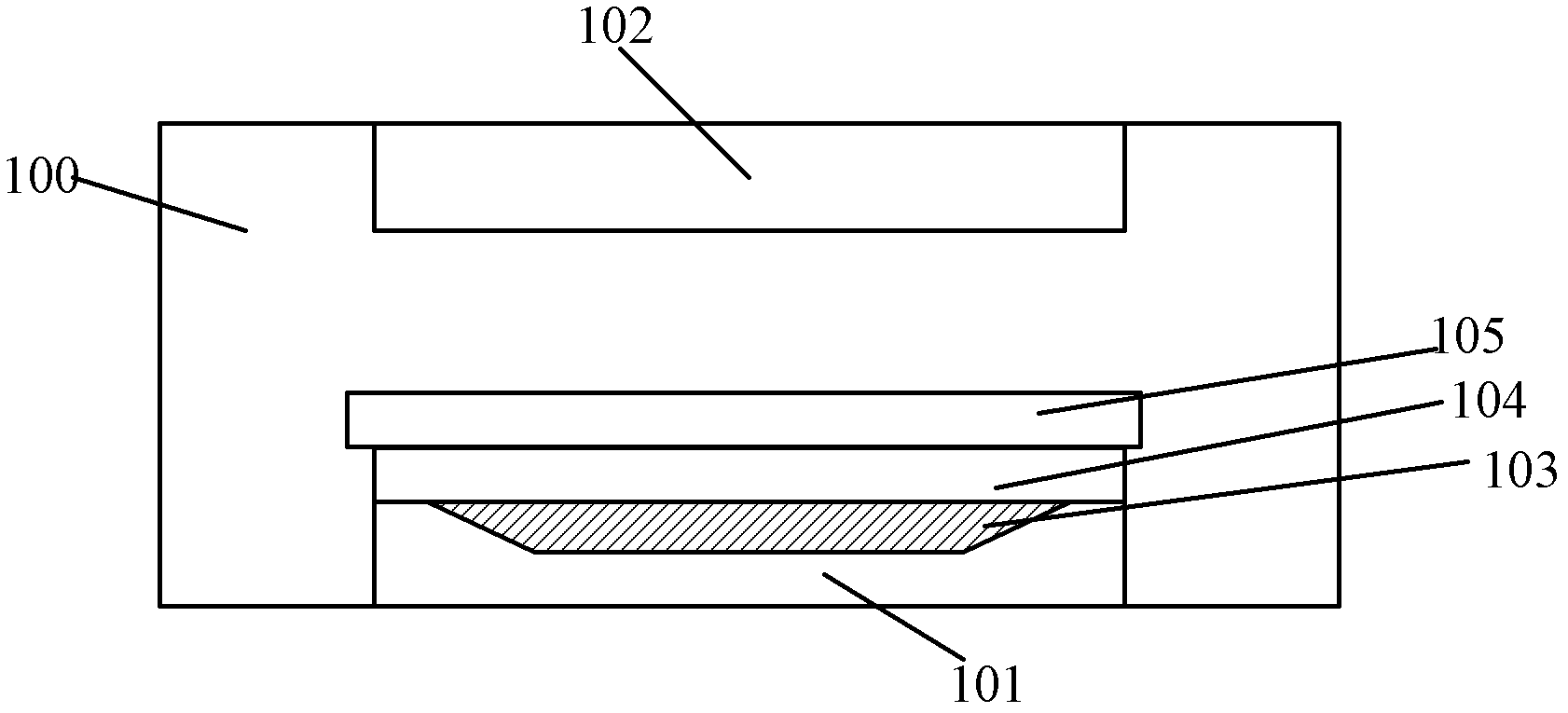

[0032] The uniformity of wafers processed by existing plasma processing devices cannot meet process requirements. After research by the inventor, it was found that the uniformity of the processed wafer was not good due to the uneven distribution of the plasma on the wafer surface during the process, and the reason for the uneven distribution of the plasma on the wafer surface was: the application of radio frequency signals The energy distribution of the first electrode or the second electrode close to the surface of the wafer to be processed (the energy in the vacuum processing chamber) is uneven.

[0033] Please combine figure 1 , taking a plasma processing device applied to a plasma etching process as an example, a radio frequency signal is applied on the second surface of the first electrode 11, and the radio frequency signal is transmitted from the second surface to the first surface along the outside of the first electrode 11 , when the radio frequency signal is a high f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com