Gasket for manufacturing touch panel, method of manufacturing touch panel using the same, and touch panel manufactured by the method

A touch panel and pad technology, applied in the input/output process of data processing, instruments, electrical digital data processing, etc., can solve the problems of residual bubbles, difficulty in manufacturing high-resolution touch panels, etc. The effect of omitting the high-temperature curing process and annealing process and increasing the margins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

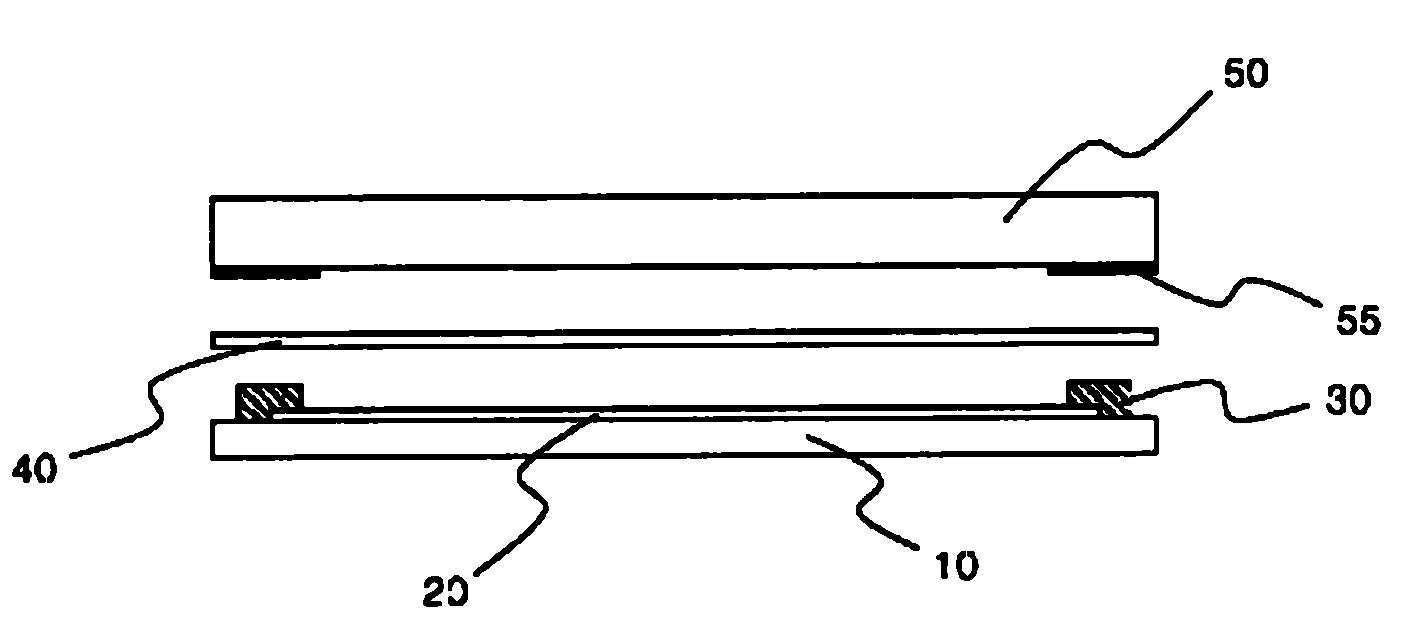

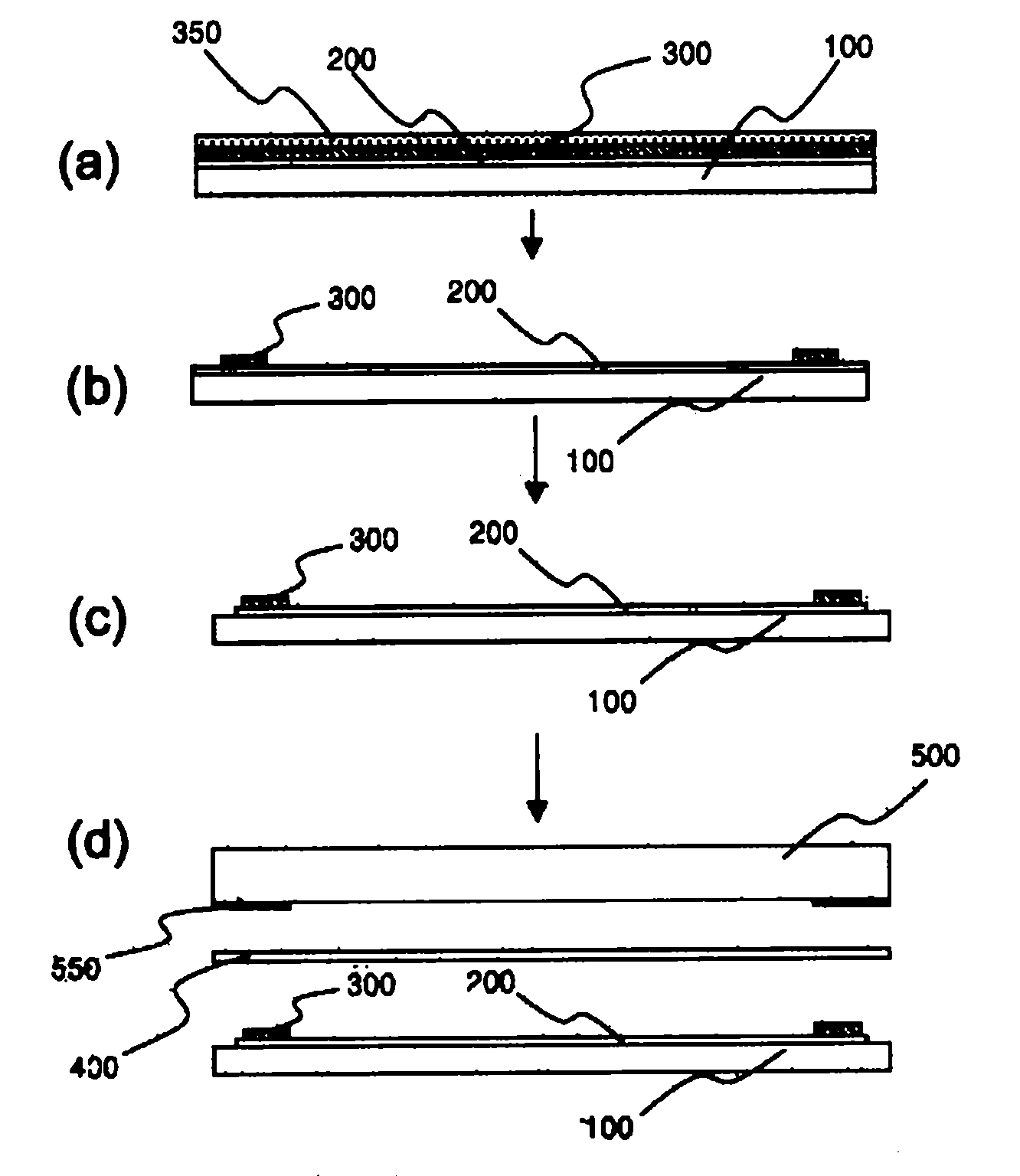

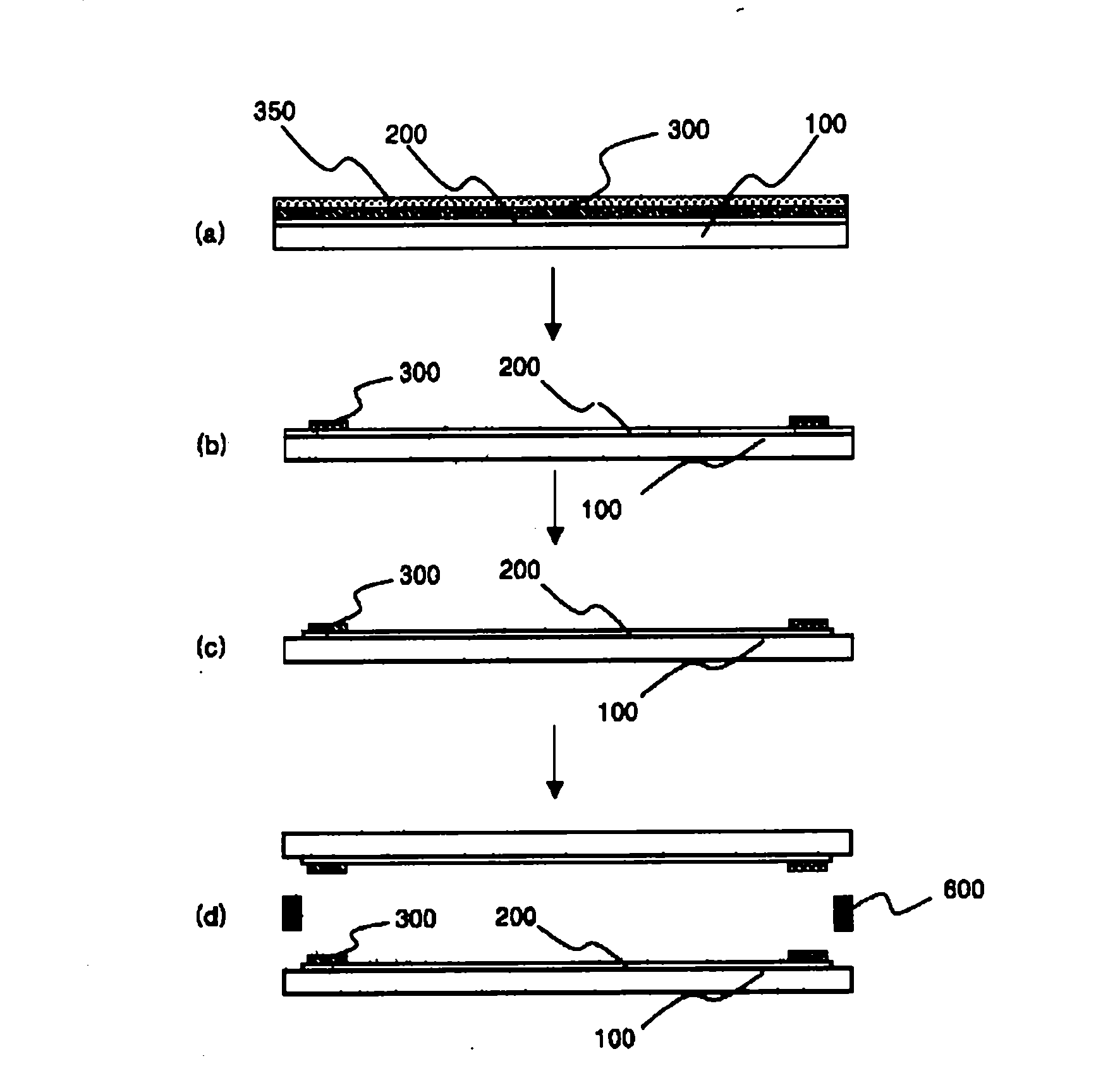

[0022] Hereinafter, the present invention will be described in detail with reference to the drawings.

[0023] The present invention relates to a pad for manufacturing a touch panel, which includes: an insulator layer 100 made of an organic insulator or an inorganic insulator; a conductive material coating 200 formed on the upper surface of the insulator layer 100; The metal coating 300 on the upper surface of the conductive substance coating 200 : and the metal protective coating 350 formed on the upper surface of the metal coating.

[0024] A specific example of this is Figure 2 to Figure 4 shown. That is, for example, in the case of a conventional touch panel, for example, i) a dielectric film (organic insulator), such as a PET film, in the case of a capacitive method, and ii) a glass (inorganic insulator) in the case of a resistive film method. Insulator), apply a conductive material coating on its upper surface, such as ITO, IZO or ATO, and then provide the material to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com